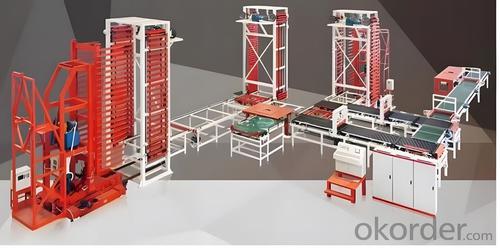

Cutting and Transporting Equipment---Upper and Lower Operation System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

The system is composed of green brick, upper and lower rack conveying, upper and lower rack machine, pallet circulation, sub-mother car, dried brick grouping, manipulator operation and other subsystems. Fully automatic operation, with an annual output of 80 million pieces (common bricks).

An upper and lower rack marshalling system suitable for secondary code burning, characterized in that: the system is sequentially provided with a blank receiving belt (1), an upper rack manipulator (2), a wet blank chain (3), a first heavy-duty chain (4), plate lifter (5), first sub-mother program car (6), drying kiln (7), second sub-mother program car (8), lower plate machine (9), second heavy-duty chain (10), tray and brick separation device (11), dry blank grouping platform (12), conveying belt (13), lower rack manipulator (14), said wet blank chain (3) and tray and brick separation device (11) A pallet supply chain (15), a transverse chain (16), and a lift chain (17) are arranged in sequence between the pallet supply chains (15), and a pallet rack (18) is also provided on one side of the pallet supply chain (15). A docking track (19) is provided between the machine (5) and the first sub-mother program car (6) and between the second sub-mother program car (8) and the lowering machine (9). The conveying belt (13) The feeding end and the discharging end of the) are respectively provided with tightening components (20)

The utility model discloses an upper and lower rack marshalling system suitable for secondary code burning, which is sequentially provided with a blank receiving belt, a rack loading manipulator, a wet blank chain, a first heavy-duty chain, a plate lifter, and a first sub-mother program car , drying kiln, second sub-mother program car, lowering machine, second heavy-duty chain, tray and brick separation device, dry blank marshalling platform, conveyor belt, lower rack manipulator, wet blank chain and tray and brick separation device. A pallet supply chain, a horizontal chain, and a lifting chain are arranged in sequence between the pallet supply chains, and a pallet rack is also arranged on one side of the pallet supply chain. A docking track is arranged between them, and the feeding end and the discharging end of the conveying belt are respectively provided with tightening components. The utility model is used for the first grouping and stacking of the wet blanks, and the racks are transferred to the drying kiln for drying. After drying, the dry billets are grouped off the shelf, stacked on the tunnel kiln car, and then entered into the kiln for roasting.

- Q: Bq: have you read elfen liedBq2: favorite quote from a book

- Kyrie- Mr. Mister Bq: No. Bq2: And in its sky was such a sun as no opium eater could have imagined in his wildest dreams. Too hot to be white, it was a searing ghost at the frontiers of the ultraviolet. (Childhood's End-Arthur C. Clarke-Chapter 16-The Last Generation)

- Q: I found one in italy. that says our machinery for beverages:-filling,-dosing, -rinsing machines, -labeling, -bending, -capping machines,-packaging and conditioning machinery, -automatic corking machines,-sterilizations sysytems i wanna know what these ^ mean to explain each of them basically and their functions for the beverage machinery.. plz help !!!!!!!!!!!!

- hh

- Q: it has for wheels and u can move around int it .... i can not think of its name!! PLEASE HELP =0

- Everybody is right; a gantry is called a cherry-picker sometimes. A scissor lift is another kind of mobile people-lifter. I saw a bulb changer driving down the hall changing lights on the high ceiling with a scissor lift. The guy changing street lamps was riding a cherry picker. Pick the one that fits the job.

- Q: Does it have all the details of the threading section? I used Machinery's Handbook for drawings to determine tap sizes, thread dimensions etc for technical drawings. I hate to buy the book again (I lost it in a flood) for the one chapter I really need. Does anyone know if it includes those tables?

- rmatc4 okorder /

- Q: How to improve the mechanical properties of materials?

- , Surface ion nitriding, can also improve the surface hardness to improve wear resistance, withdrawal can reduce the hardness of the material to reduce the brittleness to increase toughness, tempering can refine the organization, improve the stability of the material, the material surface sandblasting or

- Q: whre can i download this book?...Electric Machinery Fundamentals (Power & Energy)By Stephen J. Chapman-4th edi?

- I'm okorder /

- Q: I hate working out in public gyms and exorcise rooms if other people are there for some reason. And I hate running in public (I've ran at night before, but now I don't have any time with so much schoolwork). I was wondering what some good exorcises i can do at home every day that don't take long but will make a difference. I was hoping to work my stomach muscles more so i can get in shape for swimsuit season. Thanks! (:

- brisk okorder

- Q: green company purchased a piece of machinery on credit for 10,000.Briefly state how this transaction affect th?

- Green okorder

- Q: i want to sell a candle an unused candle extruder i bought couple of years ago, which internet sites can help me do that?

- Goto okorder

- Q: how can i acquire barrel assembly machinery for coffee bean processing?

- The okorder /

Send your message to us

Cutting and Transporting Equipment---Upper and Lower Operation System

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.