Cutting and Transporting Equipment---Stacking Bricks Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

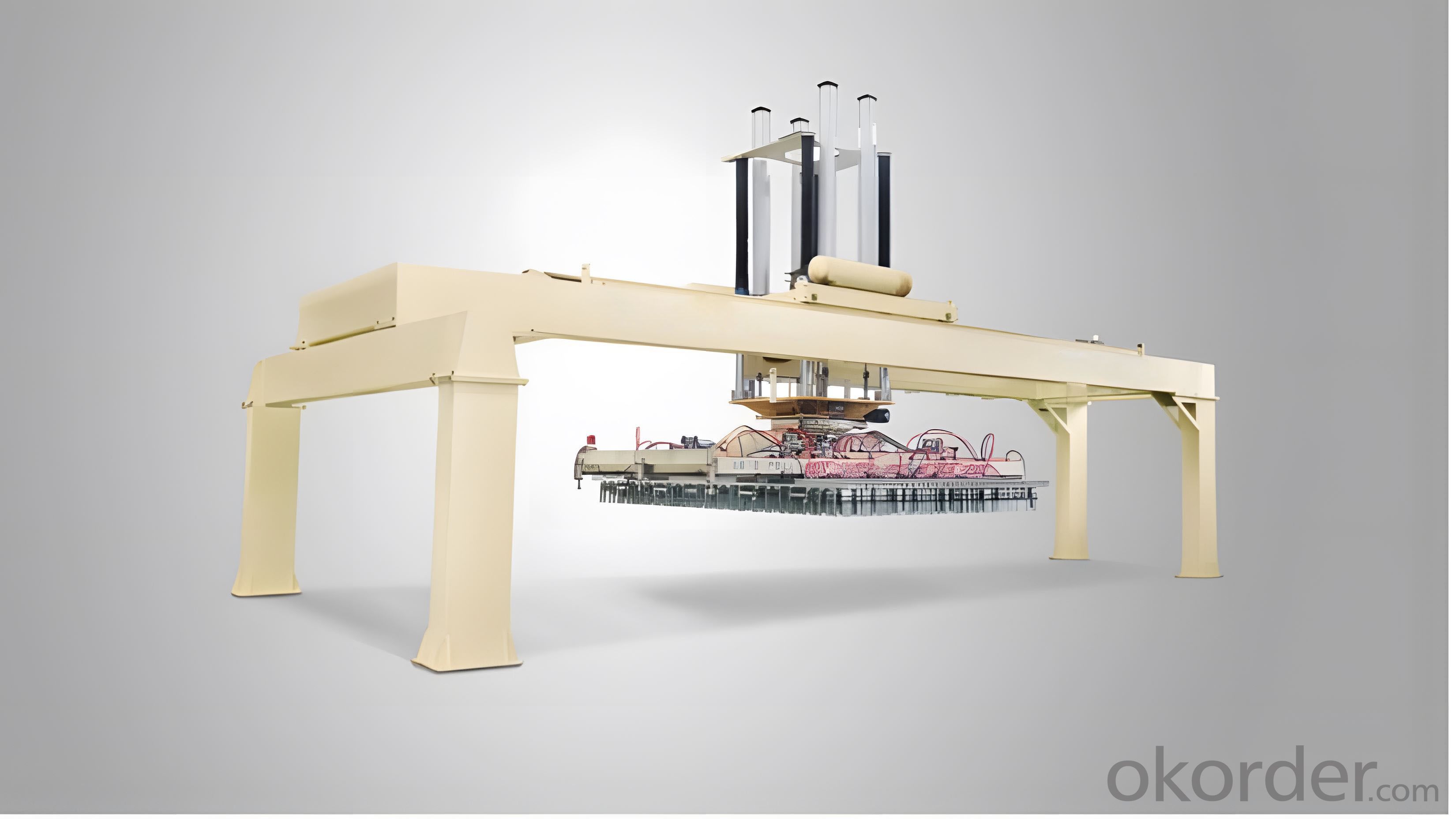

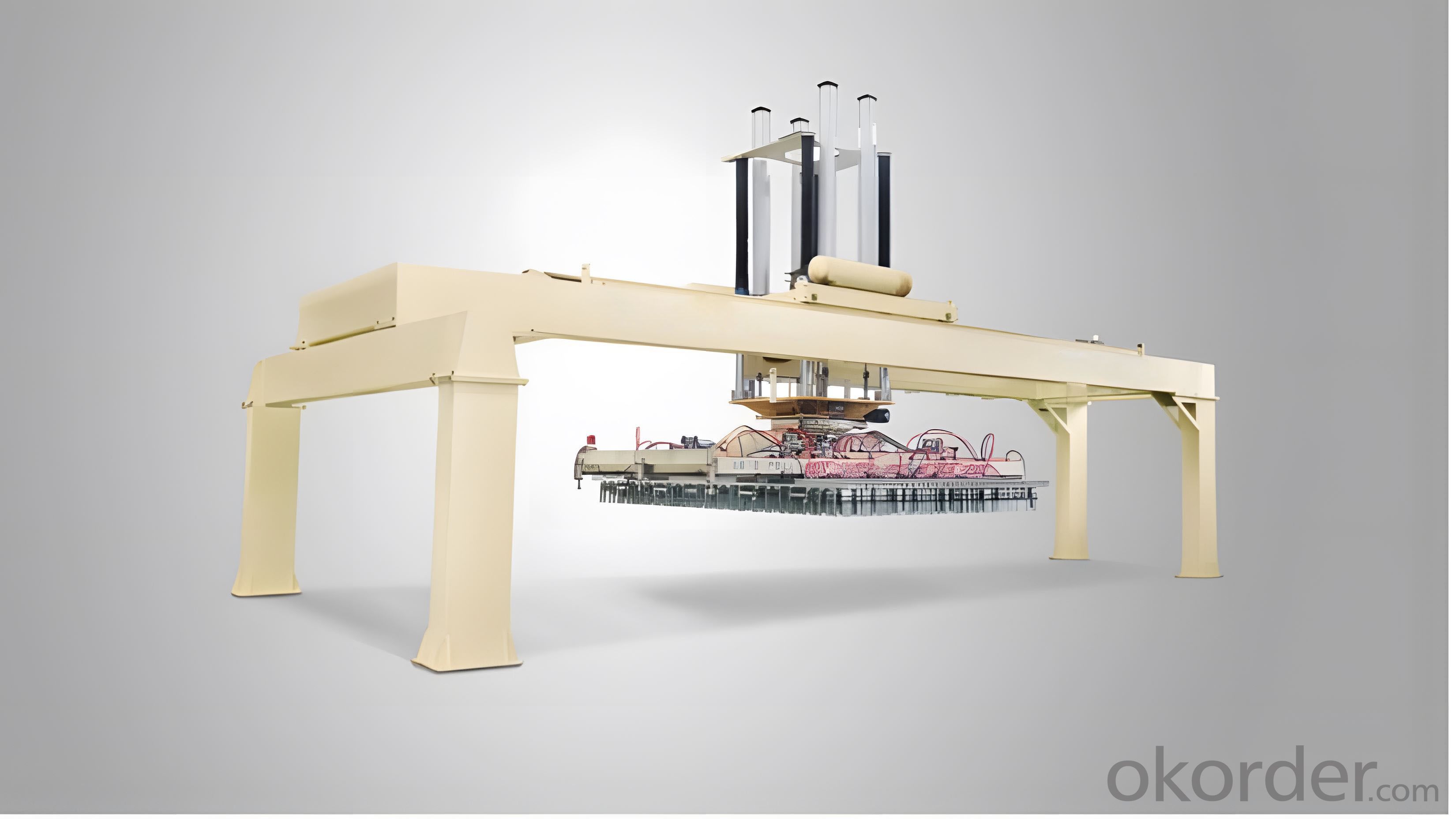

Picture1 and Picture2--Product performance:

Special press with single, double, and four-column. When changing brick types such as hollow bricks and thermal insulation blocks, the conversion of the bricks is convenient. The simple new powerful drive structure replaces the complex RV reducer to achieve a new height of load capacity and durability. It is suitable to produce multi-variety bricks and blocks and has the advantages of flexible brick conversion and low cost and can meet the medium and high output.

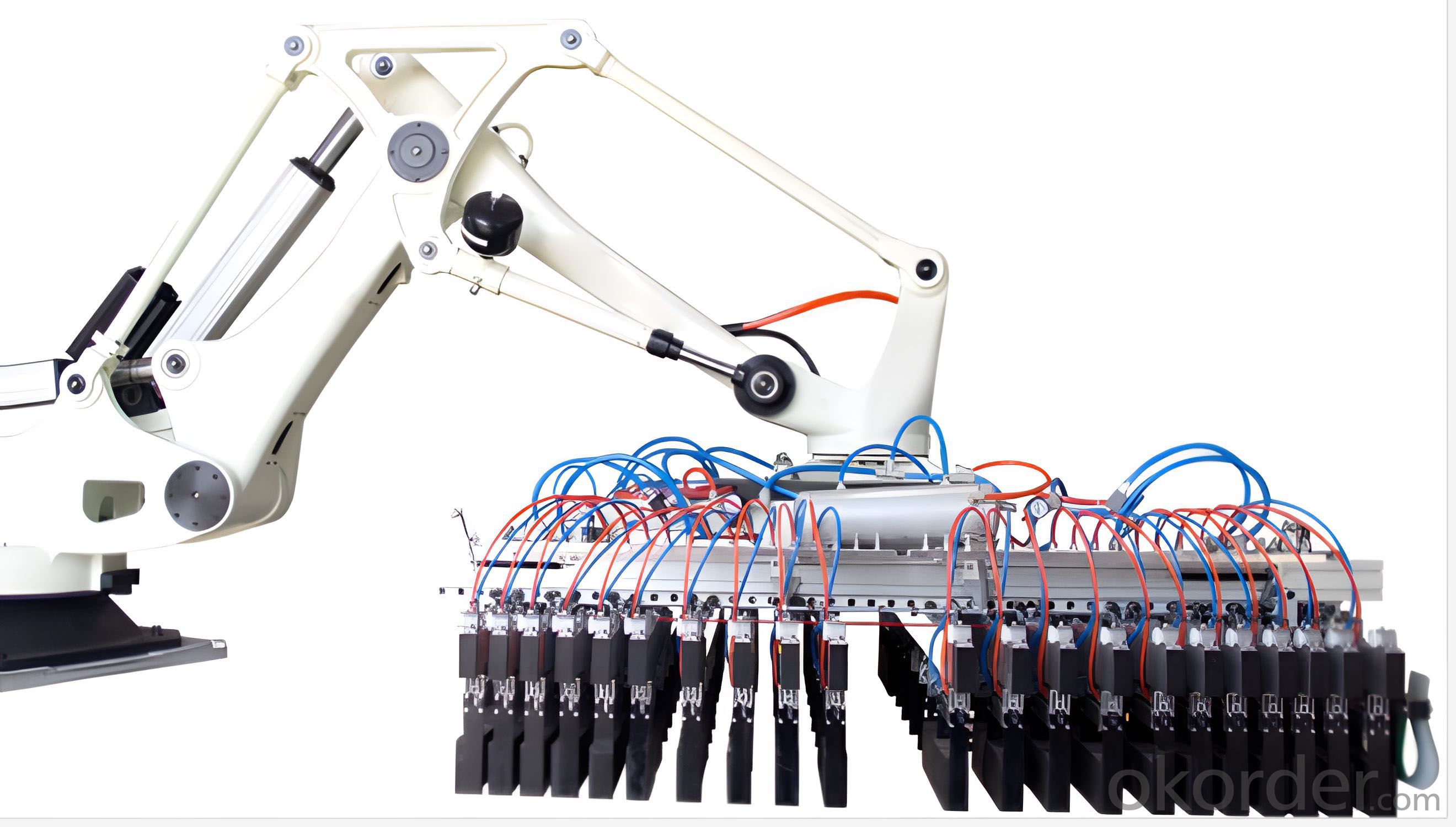

Item/Specification | ZWMR-1200 |

Structure | vertical articulation |

Flexibility | 4 |

load mass | 1200kg |

Dimensions | 3530x1000x2400mm |

Maximum working radius | 3520mm |

Repeatability | ±1mm |

Body weight | 1920kg |

Average power consumption | 11kw |

noise | 75bB |

Depending on the running attitude, some attitudes may not reach the maximum speed of each axis. | |

Picture2--Robotic hand stacks bricks

----------------------------------------------------------------------------------------------------------

Picture3--Stacking Bricks Machine

Product performance:

High-speed, high-efficiency, stable and reliable, simple operation, and convenient maintenance. It can operate a variety of brick types, change a set of chucks within 30 minutes, without affecting production; can operate long and short strips, arcs for the top layer, and compression gaps. The product has precise positioning, does not drop bricks, leak bricks, or break bricks; it has a high degree of intelligence and can realize unmanned control of the whole process; standardized spare parts design, easy maintenance, and low cost.

Parameters of Stacking Bricks Machine(Some models)

Models | Suitable for Kiln Type | Suitable for Section(m) | Capacity Per Hour (Common Brick) | Single Cycle Time(s) | Chuck |

ZWM2.2-2.8 series | Tunnel kiln, rotary kiln | 2.2-2.8 | 30 thousand | 28 | single |

ZWM3.0-4.3 series | 3.0-4.3 | 50 thousand | 36 | single | |

ZWM4.4-5.0 series | 4.4-5.0 | 60 thousand | 40 | single | |

Double chuck | 5.3 above | double |

- Q: It is related to the injection unit of molding machine

- Well, see this link.

- Q: A ers' wagesB.machineryC.trainingD.marketing

- B. machinery

- Q: Machinery was purchased for $51,000 on January 1, 2009. Freight charges amounted to $2,100 and there was a cost of $6,000 for building a foundation and installing the machinery. It is estimated that the machinery will have a $9,000 salvage value at the end of its 5-year useful life. What is the amount of accumulated depreciation at December 31, 2010, if the straight-line method of depreciation is used? $10,020. $8,580. $17,160. $20,040.

- $20,040: (51,000+2,100+6,000-9,000) / 5 = 10,020 per year 2009 - 10,020 2010 - 10,020 Total = $20,040

- Q: Is machinery still being built?

- yes it is

- Q: Can the shears machine be processed?

- According to the classification of metal materials can be cut processing: sheet; 2: plate; 3: thick plate and other materials.

- Q: Or do I have to claim my business as a medium size cooperation?

- mr. penis envy, my guess is you would have yourself an illegal medium size corporation . but that is ok, since you'll be illegal you don't have to pay taxes and the mexicans will have jobs so they can send money back to mexico to feed little mexicans. it's a win win situation! but seriously, just remember one thing though: immigrants, like the 45 illegal one's you mention, built this country so that your lazy *** can sit in front of a computer, call yourself 'penis envy' and ask moronic questions to kill time. thanks

- Q: machinery purchsed entry and derpeciation charged for it?

- The purchase: Dr. Machinery (Fixed Assets) Cr. Cash / Accounts Payable Depreciation: Dr. Machinery Depreciation Expense Cr. Machinery Accumulated Depreciation Note that the accumulated depreciation is a contra account for the fixed assets, and what appears on the Balance sheet is the net of the two figures.

- Q: this is according to marx, i think its to do with how machinery changed society from primitive to industrial, im not sure tho, any help would be gratefully appreciatedthanks

- Machines okorder

- Q: Women: Do you like to operate machinery? Weedeaters? Lawnmowers? Tillers? Tractors? Etc?

- Not really lol - - mowing a lawn is pretty boring - weedeater!! definitely not - the tractor would be the only thing that 'might' interest me :) - I'm a seamstress, I could make you a pair of jeans, that any good lol :))

- Q: Hello, our family business is rather kind of in need, to start producing our cake mixes in larger quantities.I ahve not been able to find a manufacturer that sells this amchinery. Please ask any further questions.God Bless

- you okorder /

Send your message to us

Cutting and Transporting Equipment---Stacking Bricks Equipment

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.