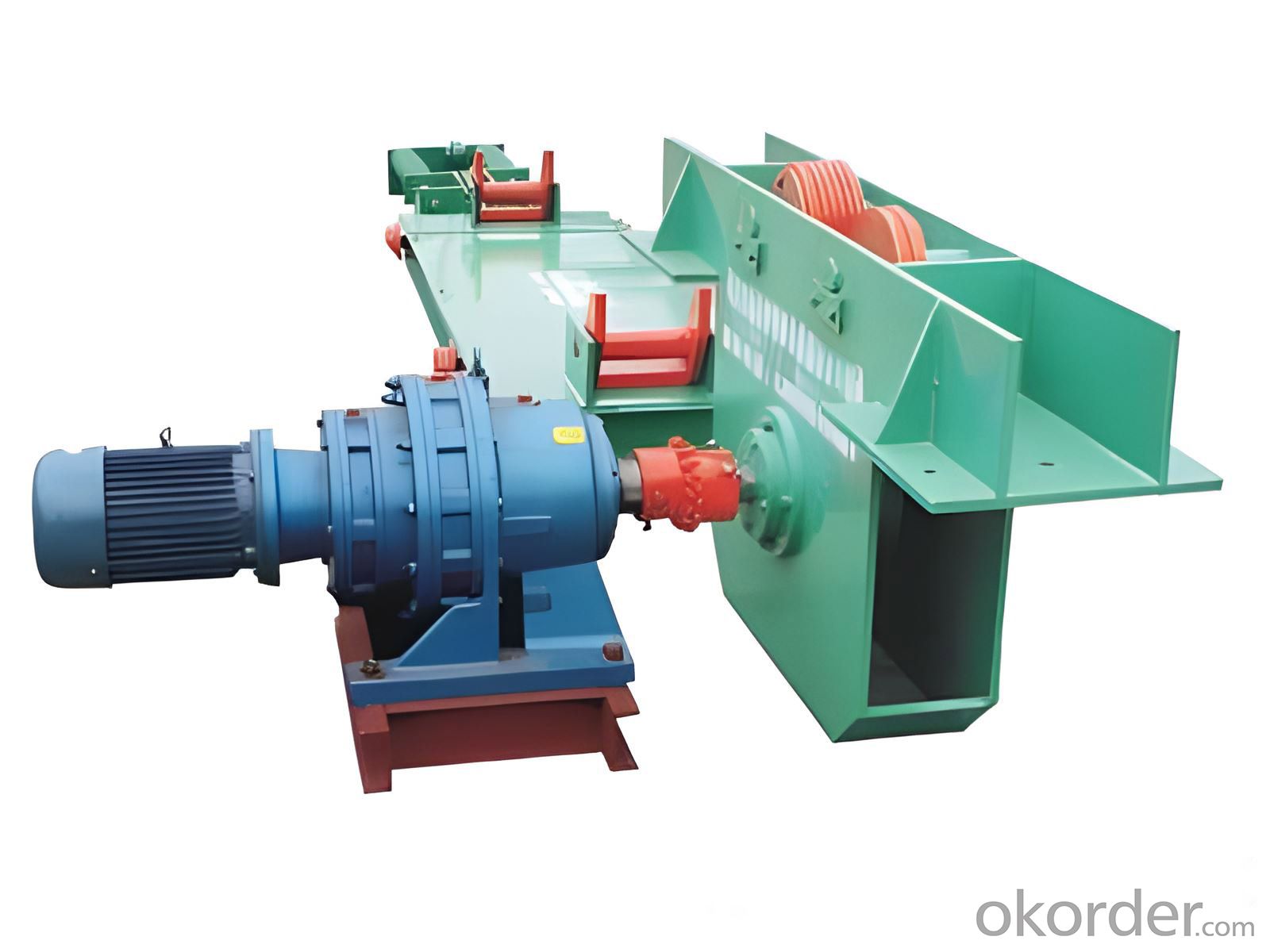

Cutting and Transporting Equipment---Operating Equipment---Positioning Stepper

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Positioning Stepper

Specifications | Max Thrust(t) | Push Speed(m/s) | Motor Power(kw) | Oil Cylinder | Applicable Kiln Type |

ZWBJ-15 | 15 | 0.04 | 11 | Ø140 Ø168 | 3.6m |

ZWBJ-20 | 20 | 0.04 | 11 | Ø150 Ø178 | 4.2m |

ZWBJ-30 | 30 | 0.04 | 15 | Ø140 Ø168 | 4.8m |

ZWBJ-50 | 50 | 0.04 | 18.5,22 | Ø180 Ø219 | 4.8m above |

ZWBJ-60 | 60 | 0.04 | 30 | Ø200 Ø245 | 4.8m above |

Kiln car and drying car are vehicles in the brick making industry that carry bricks and transport them into sintering and drying facilities. In the past, the bricks were layered and stacked in layers and stacks according to a certain structural form. When the kiln car is used in conjunction with the automatic blanking equipment, it needs to accurately reach the designated position, and during the blanking process, it needs to reciprocate and move in multiple positions according to the blanking method. At present, there are two driving methods for the kiln car to move on the track. The first is manual push, and the second is wire rope traction. Due to the use of hook connection in the way of wire rope traction, a stepping machine can only achieve one-way pulling, but cannot achieve two-way and precise movement. Manual cannot achieve accurate and fast positioning. As the size of the kiln car is getting bigger and bigger, and the method of stacking the blanks is more complicated, a kiln car may need to stack the blanks multiple times and in multiple positions. Therefore, the automation of the code blank urgently needs the cooperation of the stepping machine that can realize the linkage and precise movement with the system.

- Q: Bq: have you read elfen liedBq2: favorite quote from a book

- Muscle Bound - Spandau Ballet. 2. I'm gonna hunt you down like a rabid dog! Hunter S. Thompson.

- Q: want to go to school to be one, how long is the program and how much do they make yearly. approximately. i live in spring hill florida if that helps any.

- The median hourly wage for industrial machinery mechanics in 2008 was $20.98. The highest paid 10 percent earned more than $31.40 per hour. REad the info above..

- Q: what is the quality of a central machinery 39743?

- MINI MULTIPURPOSE MACHINE , I'd guess you'll get what you pay for, i.e.. not much. I'd imaging that within it's limited capacity is might be an adequate (depending on ones requirements) lathe, but milling capacity will be quite limited.

- Q: i've been working out on my arms for 6 months now but can't seem to get any results on the sides of my upper arms.i'm not really skinny,i'm avarage body build but i have skinny arms.i can grow muscle on front and back of my arms,but not on the sides.what are some good exercises,exercise machinery or techniques i can use to target these areas?(and sorry i don't know the technical names for these muscles in the arm)

- mattress of nails by utilising alice cooper sledgehammer by utilising peter gabriel huge undesirable John by utilising jimmy dean, confident, the sausage guy. LOL The God that failed by utilising metallica cock the hammer by utilising cyprus hill

- Q: I forgot :DI think it's some sort of generator - I know there is some piece of equipment or machinery that converts the energy in power plants...Thanks in advance!!

- Its a generator, because generators produce electricity by either moving a magnet inside of a acoil of wire or by rotating a coil of wire around a magnet, both of which use kinetic energy and convert it to electrical energy in power plants.

- Q: what rate of depreciation on new machineries purchase?

- The maximum section 179 deduction you can elect for property you placed in service in 2006 is increased to $108,000 for quali?fied section 179 property. This limit is reduced by the amount by which the cost of section 179 property placed in service during the tax year exceeds $430,000. Assuming you bought this equipment and it was placed into service in 2006, you dont have to capitalize it and depreciate it. You can elect to expense the equipment up to $108,000. This limitation gets reduced dollar for dollar for the amount of equipment placed into service in 2006 that exceeds $430,000.

- Q: Metal forming and processing methods which have their own characteristics and scope of application

- Casting the advantages are: First, you can produce complex shapes, especially the complex cavity of the rough, such as the box; Second, a wide range of applications, casting the size of unrestricted; Third, you can use low scrap as raw materials, Low; four is the shape and size of the casting and the required parts are very close, can save a lot of metal materials. Casting the shortcomings are as follows: First, the process is relatively difficult to control, easy to produce defects; Second, compared to forgings, casting performance is relatively low; Third, in some casting process, the production of small quantities, workers labor intensity.

- Q: Can the shears machine be processed?

- Shearing machine: As the name suggests is the machine to cut the sheet metal.

- Q: I know the basics - clear cut the trees, put explosives in the mountains, blow the mountain up, separate coal from waste, fill up valleys and then plant some grass. What I want to know if more about the machinery used - some sites talk about a quot;dragline,quot; but don't have any more info than quot;it is used in MTRquot; What kind of explosives are used? How do they gather/separate the coal from the mining waste?

- The explosive is a slurry of Diesel fuel and potassium nitrate that is pumped into the drilled holes for surface mining. They use Semtex and variations of it to do underground mining because of how fast the explosion is. As far as separating there is a very small amount of other materials when you are mining coal. It exists in large quantities at a pure rate. There is almost no need to separate anything from the haul.

- Q: plz help! its my homework :P ugh. thanks guys xD

- The Oxford American Writer's Thesaurus does not mention any antonyms. The opposite of a machine might be human labor. Did you mean synonym? (meaning similar) ... If so, apparatus ,hardware, gear, mechanism, gadgetry, tool, engine

Send your message to us

Cutting and Transporting Equipment---Operating Equipment---Positioning Stepper

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.