Customized Colorful Food Safe BOPP Printed Packing Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 2500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications Of Customed Colorful Bopp Printed Packing Tape:

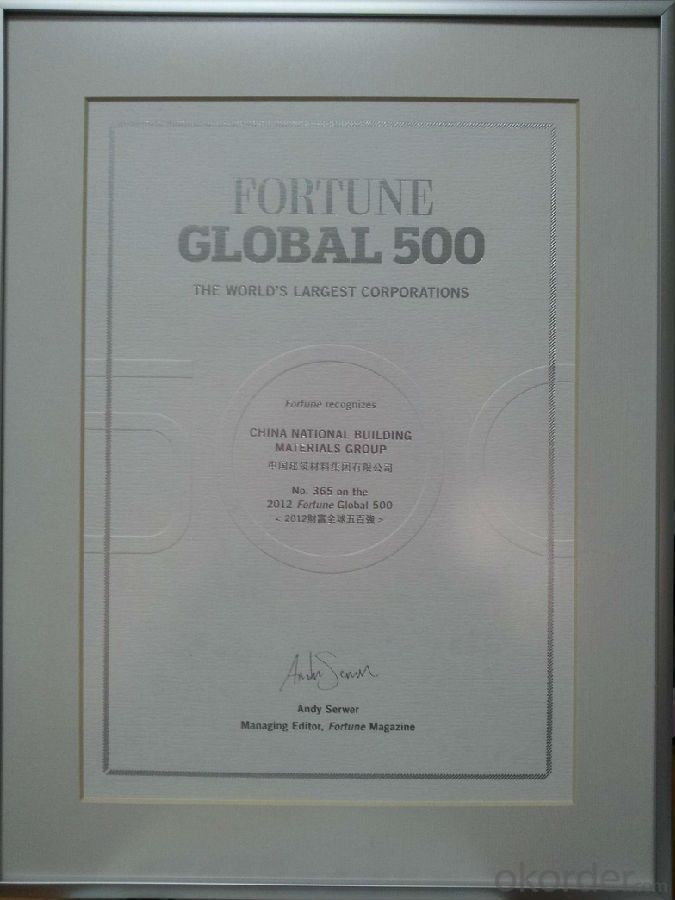

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description Of Customed Colorful Bopp Printed Packing Tape:

The Bopp Tape is of Bopp film as the carrier, coating with water based acrylic adhesive. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

General purpose of Bopp Tape: widely used for carton sealing and packaging, light duty packaging, bounding, holding and other office and household use.

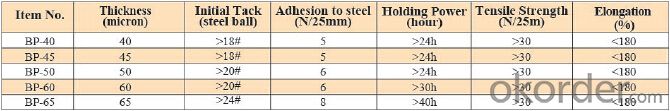

Typical Physical Reports Of Customed Colorful Bopp Printed Packing Tape:

Packaging Of Customed Colorful Bopp Printed Packing Tape:

The thickness of the tape can be customized.

Cut Roll: As per customer’s requirements

Log Roll: Width1280mm; length according to customers’ requirements

FAQ of Customed Colorful Bopp Printed Packing Tape:

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Double Sided Tissue Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: How do I prevent packaging tape from wrinkling?

- Here are some steps you can take to prevent packaging tape from wrinkling: 1. Utilize a tape dispenser: Using a tape dispenser aids in achieving a smooth application of the tape, reducing the likelihood of wrinkling. It also grants better control during taping, making it easier to keep the tape straight and taut. 2. Apply the tape tightly: When applying the tape, pull it firmly as you adhere it. This prevents any slack or loose areas that may cause wrinkling. Be cautious not to stretch the tape excessively, as this could diminish its adhesive properties. 3. Opt for the appropriate tape type: Different types of packaging tape possess varying adhesive properties and thicknesses. Selecting a high-quality tape specifically designed for packaging can minimize wrinkling. Additionally, consider using tape with reinforced fibers for added strength and resistance to wrinkling. 4. Ensure a clean surface: Before applying the tape, ensure that the surface is free from dust, dirt, or any other debris. These particles can cause the tape to wrinkle or adhere improperly. Thoroughly clean the surface and allow it to dry before taping. 5. Avoid extreme temperatures: Packaging tape can be sensitive to temperature changes, which may lead to wrinkling. Refrain from using the tape in extremely cold or hot environments. If possible, store the tape in an area with controlled temperature before usage. 6. Apply pressure: After applying the tape, use your hand or a roller to exert pressure on it, ensuring proper adhesion. This helps smooth out any potential wrinkles or bubbles and ensures a secure attachment of the tape. By following these suggestions, you can significantly diminish the likelihood of packaging tape wrinkling, resulting in a more orderly and secure package.

- Q: What are the benefits of using pre-printed packaging tape with warning messages?

- Using pre-printed packaging tape with warning messages has several benefits. Firstly, it helps to ensure the safety of the package contents and the individuals handling them. The warning messages act as a visual reminder of any potential hazards or special handling instructions, reducing the risk of accidents or mishandling. Secondly, it saves time and effort by eliminating the need for separate warning labels or writing instructions on the packaging. The pre-printed tape provides a clear and professional warning message that can be easily recognized by anyone involved in the packaging process. Lastly, it enhances the overall professionalism and branding of the company. The customized warning messages on the tape can include the company's logo, contact information, or any other branding elements, making the package stand out and leaving a positive impression on the recipient.

- Q: Does packaging tape come in different odor-free options?

- Indeed, there are various odorless alternatives available for packaging tape. Numerous manufacturers provide packaging tape explicitly crafted to be free from any scent, rendering it appropriate for utilization in delicate settings or for individuals susceptible to allergies or sensitivities towards specific aromas. Typically, these odorless choices are manufactured using materials that do not release any intense odors or fragrances, guaranteeing a neutral and enjoyable packaging experience. Before purchasing packaging tape, it is advisable to inspect the product description or labeling to confirm its odorless nature.

- Q: What course of packing and cartons do we use for our company?

- Raw material ledger ledger should set the number of value type according to the material specifications, if material specifications more, in order to prevent errors but also in warehouse and category raw materials two accounts, two accounts only income issued andbalances amount, do not remember the number.

- Q: Can packaging tape be used for sealing packages with high-value contents?

- Yes, packaging tape can be used for sealing packages with high-value contents. However, it is important to ensure that the tape used is strong, durable, and tamper-evident to provide adequate security and protection for the valuable contents.

- Q: What are the considerations for using packaging tape on wooden surfaces?

- When using packaging tape on wooden surfaces, there are several considerations to keep in mind. Firstly, it is important to choose the right type of packaging tape for the wooden surface. Opt for a tape that is specifically designed for use on wood or has a gentle adhesive to prevent any potential damage or residue. Avoid using strong adhesive tapes or duct tapes that may leave a sticky residue or even peel off the wood's finish. Secondly, consider the condition of the wooden surface. If the wood is old, fragile, or has cracks, it is advisable to take extra precautions. Applying tape directly to damaged or delicate wood may cause further harm, such as peeling off the varnish or causing splintering. In such cases, it may be better to use alternative methods for securing or protecting the wooden surface. Another consideration is the duration for which the packaging tape will be applied to the wooden surface. If the tape is only going to be used temporarily, it is generally safe to utilize most types of packaging tape. However, if the tape is intended to be left on the wood for an extended period, it is important to choose a tape that is less likely to damage the wood or leave residue when removed. Additionally, be mindful of the climate or environment in which the wooden surface will be situated. Extreme temperatures or humidity can impact the adhesive properties of the tape, potentially causing it to lose its stickiness or even damage the wood. In such cases, it may be necessary to explore alternative methods for securing or protecting the wooden surface. Lastly, always test a small, inconspicuous area of the wooden surface with the packaging tape before applying it extensively. This will allow you to assess any potential damage or residue that may occur and make an informed decision about whether or not to proceed with using the tape on the entire wooden surface. By considering these factors, you can ensure that using packaging tape on wooden surfaces is done safely and without causing any unnecessary damage or issues.

- Q: Can packaging tape be used for sealing medical or pharmaceutical supplies?

- No, packaging tape is not suitable for sealing medical or pharmaceutical supplies as it may not provide an adequate barrier against contamination or tampering. Specialized medical or pharmaceutical grade sealing materials should be used for these purposes.

- Q: How do I prevent packaging tape from becoming too sticky?

- To avoid packaging tape becoming excessively sticky, there are several precautions you can take: 1. Keep the tape in a cool and dry location: Excessive heat and humidity often lead to the adhesive on packaging tape becoming stickier. It is important to store the tape in a cool and dry environment to maintain its proper consistency. 2. Prevent contact with dust and debris: Dust and debris easily adhere to the adhesive side of the tape, increasing its stickiness. Keep the tape away from dusty surfaces and ensure that the areas where you plan to apply the tape are clean and free from loose particles. 3. Utilize a tape dispenser: A tape dispenser aids in controlling the amount of tape you use and prevents excessive stickiness. It allows for a more precise application, ensuring that you do not use more tape than necessary. 4. Avoid excessive stretching of the tape: Stretching the tape excessively while applying it can cause it to become stickier. Apply the tape smoothly without pulling or stretching it too much, as this can activate the adhesive further. 5. Consider using low-tack or removable tape: If you frequently encounter problems with sticky packaging tape, you may consider using low-tack or removable tape. These types of tape have less aggressive adhesive properties and are easier to remove without leaving sticky residue. By following these guidelines, you can maintain the desired level of stickiness on your packaging tape and streamline your packaging process.

- Q: Can packaging tape be used for sealing construction or building materials?

- Indeed, packaging tape possesses the capability to seal construction or building materials. Although it lacks the endurance and strength found in specialized construction tapes, packaging tape can serve as a temporary or expedient remedy for sealing materials like cardboard, plastic sheets, or lightweight panels. It is suitable for fastening interim covers, affixing protective layers, or keeping materials secure throughout construction or renovation endeavors. Nevertheless, for extended or demanding applications, it is advisable to opt for tapes explicitly engineered for construction, as they exhibit superior resistance against weather, UV rays, and possess enhanced adhesive properties.

- Q: Can packaging tape be used for sealing packages with heavy-duty construction materials?

- Yes, packaging tape can be used for sealing packages with heavy-duty construction materials. Packaging tapes are designed to provide strong adhesion and durability, making them suitable for securing packages containing heavy-duty construction materials. However, it is essential to choose a packaging tape specifically designed for heavy-duty applications, such as reinforced or extra-strong tape, to ensure proper sealing and secure transportation. Additionally, it is advisable to reinforce the packaging with additional tape or protective wrapping, depending on the weight and fragility of the construction materials, to ensure safe and secure delivery.

Send your message to us

Customized Colorful Food Safe BOPP Printed Packing Tape

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 roll

- Supply Capability:

- 2500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords