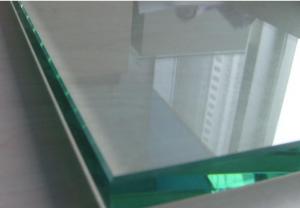

Curved Tempered Glass 4-19mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meters Bent tempered glass sample is available m²

- Supply Capability:

- 10000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery of Curved Tempered Glass

Packaging Details: Wooden crates with paper between each two sheets

Delivery Detail: Within 15 days after received deposit or L/C at sight

Specifications of Curved Tempered Glass

1.Bent Tempered Glass

2.10 years' experience

3.Best quality with CE & ISO9001

4.Competitive price and quick delivery

Bent Tempered Glass adopts the similar process with tempered glass, but before the cooling process, using the external power bent the glass to a proper radian according to the requirement, its wind pressure resistance is better than flat tempered glass and other kinds of glass for the special shape. It widely use in esthetics architecture field for the beautiful appearance.

Application of Curved Tempered Glass:

Facades and curtain walls

External walls of revolving doors and exposed elevators

Stairs, handrails, skylights

Partions, display shelves and furniture

Specifications of Curved Tempered Glass:

Thickness: 4-19mm

Min. Size: 220*430mm

Max. Size: 2440*4200mm

Curve depth: up to 500mm

Bending angle: up to 90’’

Quality Standards:

GB 15763.2, Chinese standard.

EN 12150.1, European Standard.

AS/NZS 2208, Australian standard.

- Q: What's good with a cup?

- Pure porcelain, porcelain, glass, these basic is non-toxic and good some of the porcelain. The problem is that plastic, buy when you should pay attention to:1. see, look at the material are impurities.2., smell, if there is a pungent odor, it is recommended not to buy. Attention to drinking hot water, this cup is very bad for the body.

- Q: What's the raw material for organic glass fiber reinforced plastic? Thank you.

- Plexiglass is made up of reinforcing material and cementing agentReinforcing material: glass fiber, cloth, felt and bandAdhesives: Unsaturated Poly I ester resin, epoxy resin, vinyl resin, phenolic resin and so onOther: curing agents, accelerators, fillers, etc.

- Q: What are the cutting and cutting of acrylic and aluminum-plastic plates?

- Acrylic comes from English Acrylic, generic name for Acrylic acrylic and methacrylic acids chemicals. Including monomers, plates, aggregates, resin and composite material, acrylic acid methyl ester by methyl monomer (MMA) polymerization, namely polymethylmethacrylate (PMMA) organic glass plate, "organic glass" from the name "Oroglas" (a PMMA), from the "Organic Glass" (organic glass).

- Q: Is glass steel pipe used for re examination?

- The main construction phase: a layer structure (scheme, technical disclosure basis has been included, steel raw materials, testing report report, flash butt welding, electroslag welding sampling, sample, steel concealed, reinforcing steel bar, batch inspection, template technology review).

- Q: What kind of material is made of automobile glass?

- Compared with ordinary glass, automotive glass is glass, broken is very small granular, may reduce damage. Automobile front windshield PVB interlayer, strong ability uprising.

- Q: What kind of glass is smoked glass?

- * basic materials for glass makingSilica is the main raw material made of silica on the earth reserves is great. Silica is the main raw material for the main raw material is made of glass stones. The silicon content of different rocks are different. In our life of these materials is the most common.

- Q: Which brand of thermos cup is safe, double glass is not really glass, there is no other add, affect health?

- Double glass also called light industrial glass, raw materials for high boron silicon has a high heat resistance, the main production of glass teapot, coffee cup, cup, cup of hot water, there are many domestic manufacturers.

- Q: What are the Department of mobile phone lens?

- Well, yes, coating is coated, but not what you said, the film, this forgot to say, but generally speaking, is this, in fact, is not very complicated process, as long as there is equipment, it is easy to handle!

- Q: Which is the best solar water heater tube?

- The color of the vacuum heat collecting tube is mainly blue and black, and the overall chromatic aberration is small. But black does not indicate the quality of vacuum heat collecting tube is good, because some manufacturers in order to cover up variegated, often made of pure black film. In fact, there is a certain error in the color of the vacuum heat collecting tube, which is unavoidable, and does not affect the heat collecting efficiency of the vacuum heat collecting tube.

- Q: The difference between natural crystal and crystal glass, merits and demerits!

- Crystal glass according to PBO (lead oxide) content is divided into high (24%PBO and above), medium (18%PBO), low (12%-16%PBO) three grades. Grading standards are similar to gold. International standard crystal glass is 24%PBO, so merchants will also call this class "24K"". If you go to buy, say some similar "jargon", the other party will feel that you are more adept, encountered illegal businesses, nor dare to fool you.

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2004 |

| Annual Output Value | |

| Main Markets | South America 28.97 Eastern Europe T 9.66 Southeast Asia 0.63 Africa19.31 Oceania 1.45 Mid East 14.49 Eastern Asia14.49 Western Europe 1.11 Central America 4.83 Northern Europe 0.96 Southern Europe 1.59 South Asia 0.48 North America 2.03 |

| Company Certifications |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | percent of export |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b) Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Curved Tempered Glass 4-19mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 Square Meters Bent tempered glass sample is available m²

- Supply Capability:

- 10000 Square Meters per Day m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords