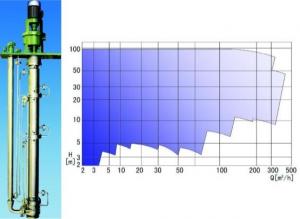

CTN / -H,Radially split, vertical shaft submersible pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Design |

Overview of technical data

| Type of impeller | Radial; Closed |

| Maximum drive rating | 290 kW |

| Impeller material (EN standard) | JL 1040; 1.4408 |

| Type of bearing | Rolling element and plain bearings |

| Drive frequency | 50 Hz / 60 Hz |

| Maximum speed of rotation | 3. 500 1/min |

| Maximum flow rate | 980 m³/h |

| Maximum discharge-side pressure | 16 bar |

| Top plate | Yes |

| Casing material (EN standard) | 1. 4408;JL 1040 |

| No. of impeller entries | Single entry |

| Casing material | Cast iron; Stainless steel |

| Minimum flow rate | 2 m³/h |

| Suction characteristics | Non- priming |

| Drive voltage | Low voltage |

| eClass assignment | 36410000; 36410100;36410101 |

| Pump set location | Dry installed, floodable |

| Heatable | Yes |

| Max. permissible fluid temperature | 300 °C |

| UNSPSC classification | 4015150300 |

| Main applications | Industry and process engineering |

| Type of installation | Stationary |

| Type of casing | Volute casing |

| Type of connection | Flange |

| Type of lubrication | Grease / Oil lubrication |

| Type of drive | Electric motor |

| Installation position | Vertical |

| Shaft material (EN standard) | C45SH+ S;1.4571 SH |

| Type of coupling | Direct |

| Shaft seal type | Gland packing; Mechanical seal |

| Maximum head | 135, 00 m |

| Maximum rated pressure (discharge) | PN 16 |

| Minimum head | 3, 00 m |

| Nozzle position | Variable |

| Casing partition | Radially split |

| Maximum submergence | 9. 500 mm |

- Q: I am looking for the solutions manual. I have searched cramsters, etc. and no luck.

- I saw that book recently at a store, and I think it's called Design of Machinery with Student Resource, not solution manual. Good luck with this. Sometimes with searches it really depends on the exact phrasing.

- Q: Were the Luddites justified in their attacks on machinery?

- Turning point in history Many historians would deem the Luddite riots as unsuccessful, while many others would say that they had a huge impact on society. The Luddites changed the views of people during the Industrial Revolution. They brought the rights of the workers to the attention of England. A turning point in history is often thought of as a well-known and dramatic event that took place and completely changed the world. The riots of the Luddites are not very well-known. However, their actions led to many significant changes in the world. Politically, the actions of the Luddites brought the idea of having a society based on industrialization into the eyes of the public and open to debate. People were forced to look more closely at the positive and negative effects of having an industrial society. The machine question continues tobe unanswered today. The riots became a turning point because the flaws of the Industrial Revolution were brought to the surface and the government could no longer ignore the opinions of the working class. The Luddites stories circulated England, showing the strong resistance and bravery of the English men. People realized that if one is disciplinedand organized, he will be successful in his battles. The Luddites als brought about the ideas that technology is never neutral and some are even hurtful. For example, while the while the Spinning Jenny was beneficial to the textile industry, it also put several spinners out of business. The Luddite rebels uncovered the dark side to the Industrial Revolution!

- Q: Hi,I would like to have machinery and machine in sentence so that I can understand the meaning

- A sewing machine is a mechanical device used for sewing cloth. A sewing machine is a piece of machinery.

- Q: What are the common mechanical processing methods?

- Common mechanical processing methods are turning, milling, grinding, boring, drilling, wire cutting, EDM, etc..

- Q: I am not talking about homemade reloading. I'm talking about pooling up some money with some of my friends to buy commercial bullet/ammunition making machinery equipment, to manufacture our own ammunition from scratch, from the basic materials such as powder, lead, brass, and copper to the finished product = 1 fully assembled round of ammo.Due to the ammo shortage I see now, I see a great investment and commercial opportunity. Lead, copper, brass, and powder can be found in vast quantities, but ammo is in a shortage. But if I have the machines to melt, process, and combine these materials, I no longer have an ammo shortage. Where can I buy commercial ammo making machinery?

- Ammunition Manufacturing Equipment

- Q: Japan famous construction machinery and electric company

- Engineering machinery: Komatsu construction machine, Hitachi, Kobelco, and Yanmar, Sumitomo, ah, ah, a lot of Electric: Hitachi, Matsushita, SONY, Toshiba

- Q: big machinery for tortilla making

- try a resteraunt supply place or use a hand powered one. Those you can find in any mexican store.

- Q: please suggest the machinery name cost involve to set up a small scale fruit juice processing factory which production capacity is 2 ton per day?

- Very okorder / ... I googled commercial juice processing equipment

- Q: When a crematorium, for instance, which is not an industrial building but requires heavy machinery, is constructed, are the environmental systems, like HVAC and mercury abatement systems, or the actual furnaces themselves brought to site in pieces and assembled at first fix stage or put in place before the roof or slab above goes on? Or are they just serviceable by a separate large entrance?

- Large entrance is best. Long ago setting equipment then constructing the walls was a common practice. When the original machines need to be replaced it is a problem.

- Q: Does anyone know the process and machinery a Dye Works would have used in the 1900's?

- Having okorder /

Send your message to us

CTN / -H,Radially split, vertical shaft submersible pump

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 100 unit/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords