Cow Carpet Geotextile Geocomposite Drain for Road, Railway, Highway, and Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Geocomposite Drain for Road Railway Highway Tunnel

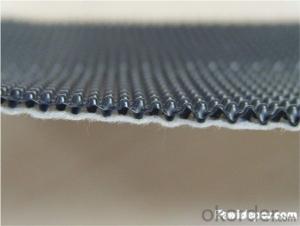

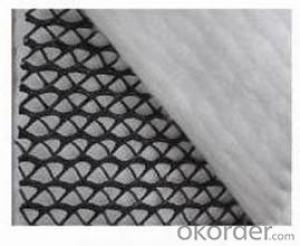

Geocomposite drain is made of fiber extruded from thermoplastic synthetic resin. It is a tri-dimen-sional material with many holes. There is a geotextile layer outside the geocomposite drain, whose main function is to sieve sand and clay so as to avoid blockage. This product has four shapes, but mmany types, including rectangular with many holes, round shape with many holes, round shape but hollow ones.

Specification of Geocomposite Drain for Road Railway Highway Tunnel

Circular shape size D50, D70, D80, Rectangle 70X30, 120X35, 300X35, 400X35.

Property of Geocomposite Drain for Road Railway Highway Tunnel

High pressure resistance, high opening rate in surface, excellent in collecting and draining water, permanent lifetime, easy for construction, good flexibility and adaptable to the earth distortion.

Application of Geocomposite Drain for Road Railway Highway Tunnel

Drainage for tunnel, roadbed and road shoulder of highway, railway, soft bed disposal, remaining wall filtration, underground building d rainage and anti-tidal air, also water collecting and draining in green field, roof garden, sewage disposal, garbage bu rying field and other works.

- Q: How do geotextiles affect soil compaction?

- Geotextiles can help reduce soil compaction by providing a barrier between the soil and external forces. They distribute the load evenly, preventing the soil particles from being compressed too much. This allows the soil to maintain its natural structure and porosity, resulting in improved drainage and increased resistance to compaction.

- Q: Can geotextiles be used in the construction of wastewater treatment plants?

- Yes, geotextiles can be used in the construction of wastewater treatment plants. Geotextiles are commonly used in various applications within wastewater treatment plants, such as filtration and drainage systems, erosion control, and soil stabilization. They help enhance the overall efficiency, durability, and environmental sustainability of the treatment plant infrastructure.

- Q: What are the different geotextile installation equipment and tools?

- Some of the different geotextile installation equipment and tools include geotextile dispensers, spreaders, rollers, staplers, and anchors. These tools are used to ensure proper placement and securement of geotextiles in various construction and environmental applications.

- Q: Cement concrete bridge is a film curing or geotextile maintenance

- Commodity concrete pouring is completed, should be in the slurry after grinding as soon as possible to cover and sprinkler conservation. Commodity concrete bridge deck with full coverage of sprinkler conservation methods, covering materials with two sticky one geotextile, every 1t sprinkler once, to ensure the quality of conservation, to prevent cracks.

- Q: How do geotextiles help in gas venting?

- Geotextiles help in gas venting by providing a permeable barrier that allows the passage of gases while preventing the migration of soil particles. This allows gases, such as methane, to escape from the ground, reducing the risk of buildup and potential hazards.

- Q: Is there a filament geotextile manufacturer? Introduce the main performance ah

- Our road embankment reinforcement project, for example, the construction of the road first focus on the quality of the road followed by the use of these two problems, and Hongxiang new material filament geotextile just to solve. In order to improve the smoothness of the road to prevent the occurrence of reflective cracks and play the role of waterproof layer. Laying and impregnating the asphalt between the base layer and the surface layer to form the filament geotextile - asphalt interlayer. You can see the specific understanding of the user name

- Q: What are the maintenance requirements for geotextile-reinforced retaining walls?

- The maintenance requirements for geotextile-reinforced retaining walls typically include regular inspections for signs of erosion, damage, or structural issues. Additionally, any vegetation growing near the wall should be monitored and removed if it poses a threat to the integrity of the structure. It is also important to ensure proper drainage and prevent water buildup behind the wall. Regular cleaning and removal of debris is necessary to avoid blockages and maintain the functionality of the drainage system. Overall, following manufacturer guidelines and conducting routine maintenance activities will help ensure the longevity and effectiveness of geotextile-reinforced retaining walls.

- Q: what is the life span of a geotextile tube ?

- Engineered geotextiles have design lives of up to 120yrs. It depends on what geotextile you are talking about and what environment it is placed in.

- Q: Does geotextile affect water purification?

- Do not know what you use after the purification of water, if not drinking water, I think it will not affect the water quality, the general purpose of water purification, geotextile will not affect, because the geotextile material is polyester or polypropylene, In the chemical nature of relatively stable, no changes in room temperature conditions, so there will not be any impact on water quality

- Q: Geotextile (two cloth a film) to detect the frequency requirements? On behalf of the number?

- Geotextile and geomembrane detection frequency is 100 volumes detection time.

Send your message to us

Cow Carpet Geotextile Geocomposite Drain for Road, Railway, Highway, and Tunnel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 5000rolls m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords