High Alumina Corundum and Mullite Bricks for Hot Blast Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

CNBM Group is listed No.187 in on Fortune Global 500, 2020.

Refractory is one of the main products of the group. At the same time, under the globalization strategy, CNBM International is the exporter, logistic and local service supplier.

13 Refractory plants locate in 9 different cities

15 professor level senior engineers,239 engineers,5 senior experts committed Iron & Steel industry

Annual production capacity is over 400,000 tons.

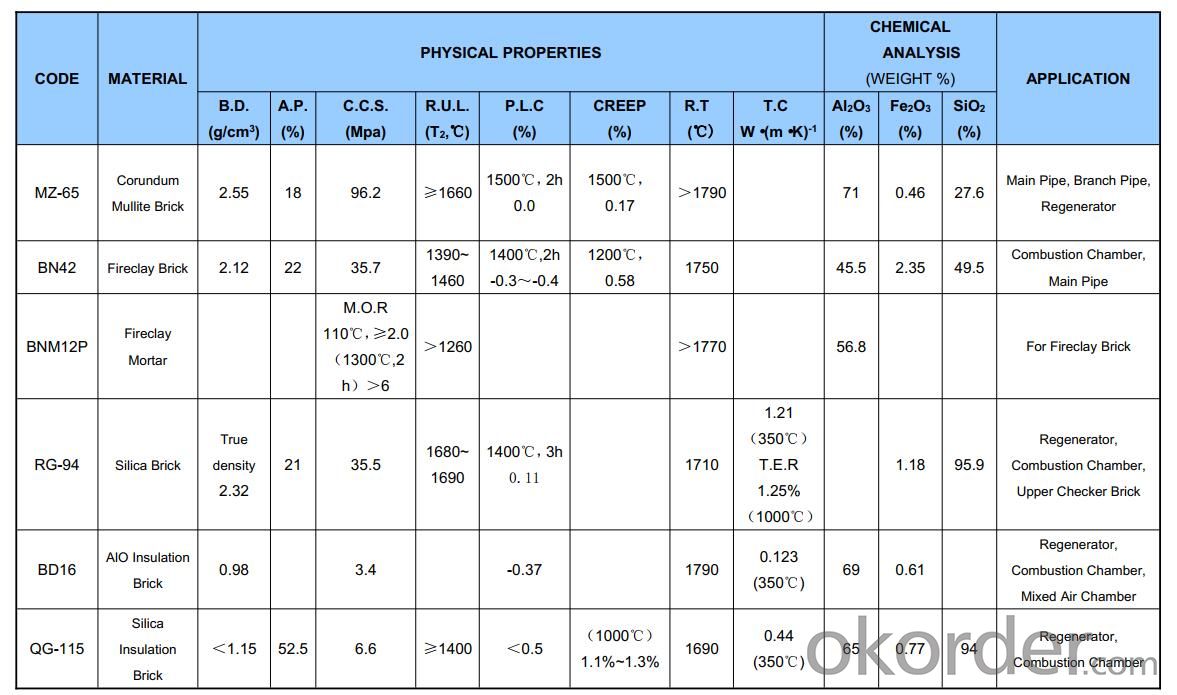

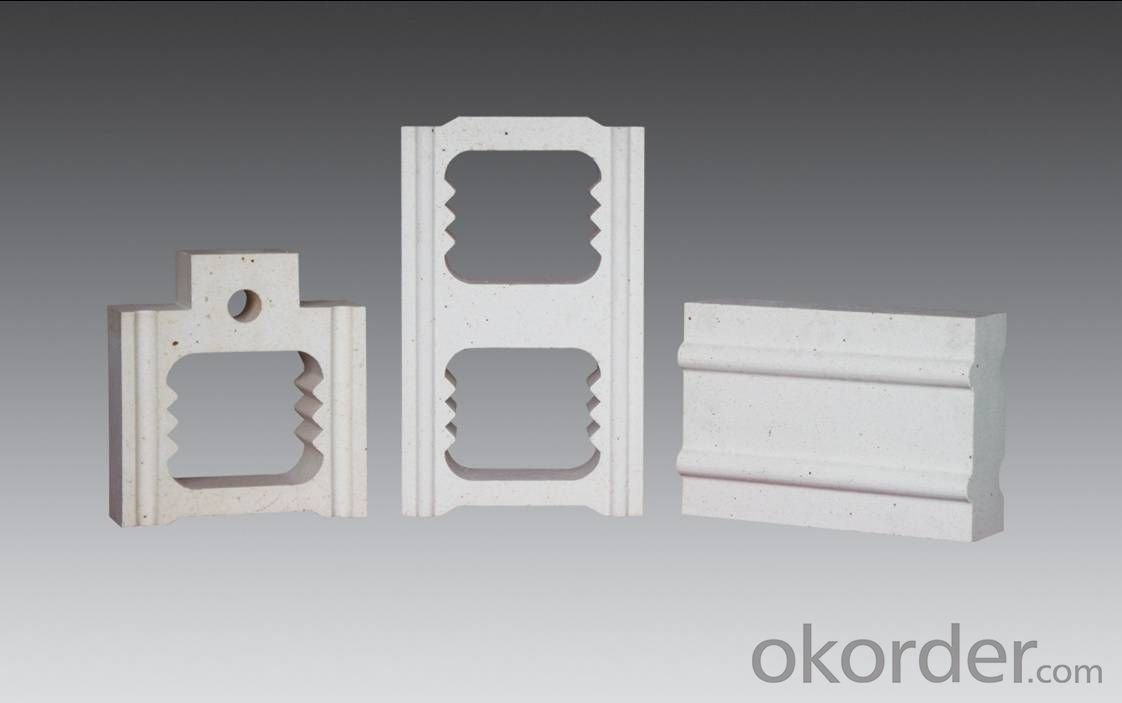

Product Name: Corrundum Bricks and Mullite Bricks for Hot Blast Furnace

Features:

Good corrosion resistance

Good thermal shock resistance

Technical Data Sheet For Corrundum Bricks and Mullite Bricks for Hot Blast Furnace

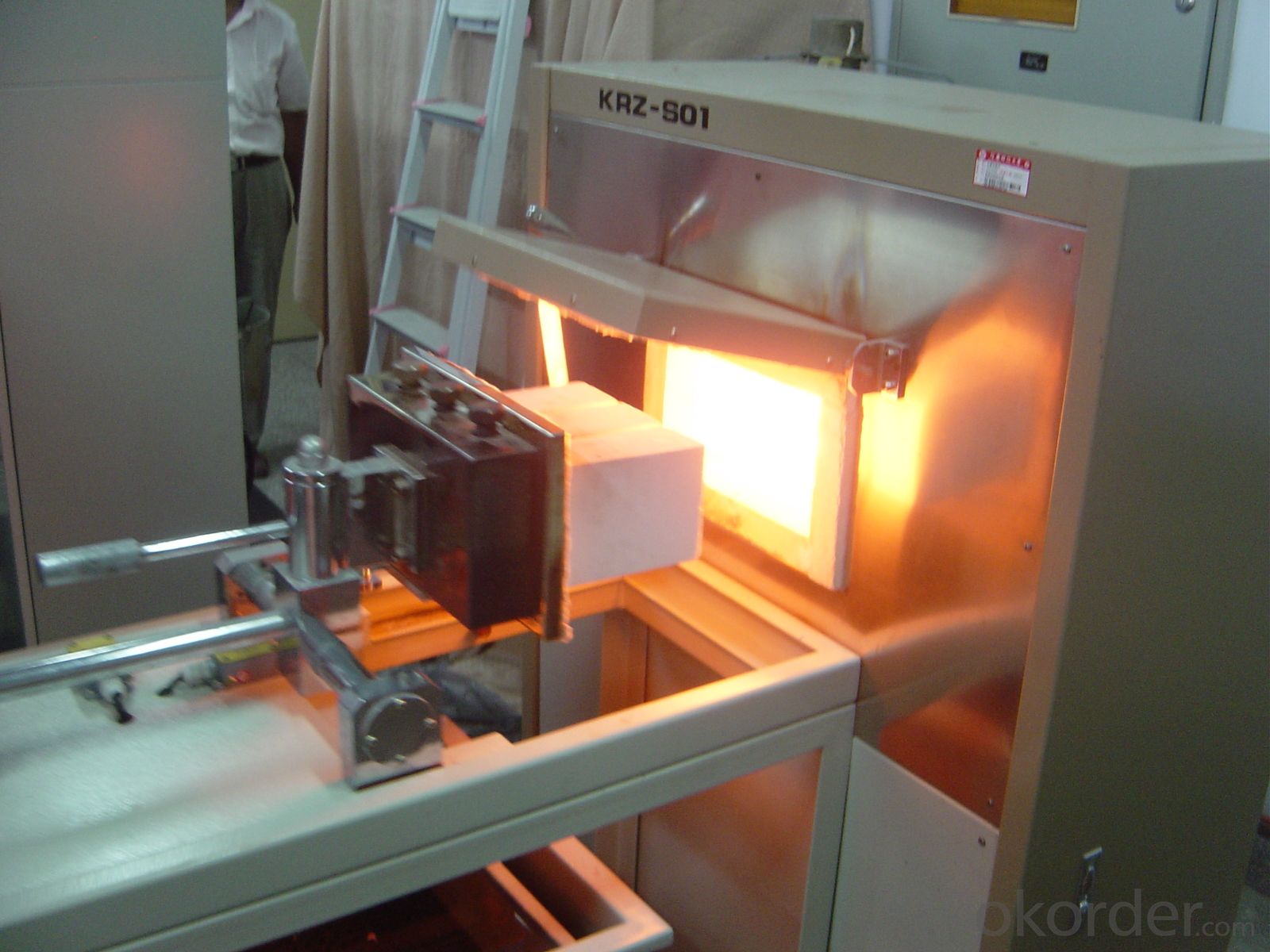

Product Photos of Corrundum Bricks and Mullite Bricks for Hot Blast Furnace

Our workshop

- Q: In 2016, a few of the traditional refractory materials will be able to survive

- From the year 2015 to the year 16 the end of the year, refractories industry presents two kinds of situations: one is a small business, a single product variety and equipment, to meet the demands of both environmental protection and the downstream market, such enterprises are generally in the Qing state inventory;

- Q: What is the heat preservation material used in a laboratory furnace?

- Thermal insulation cotton is a high-purity clay clinker, alumina powder, silica powder, chromium sand and other raw materials in the industrial furnace melting at high temperature, forming fluid. Then, compressed air is used to blow or use the wire throwing machine to turn the yarn into a fiber shape. After the cotton collector is collected, the cotton is formed into a heat preservation cotton.The high alumina brick is usually made of high alumina clinker with small amount of clay. After grinding, the high alumina brick is poured and shaped in the form of slurry by the way of gas generation or foam, and it is burnt at 1300~1500 DEG C. Sometimes industrial alumina can be used instead of some bauxite clinker. Used for lining and insulation of masonry kilns, as well as for areas where there is no strong, high temperature molten material erosion and erosion. When contacting the flame directly, the surface contact temperature shall not be higher than 1350 degrees centigrade.

- Q: What are the grades of high alumina bricks?

- High alumina brick according to the aluminum content is generally divided into: super high alumina brick, a high aluminum brick, two high alumina brick, three high alumina brick

- Q: What are the reasons for the decline in the performance of high alumina bricks when we use high alumina refractory bricks?

- All the raw materials adding order, mixing time, material and material moisture trapped. 4, the pressure and the volume density of Pei brick and brick Pei size etc..

- Q: What's the difference between a well type annealing furnace and a box type annealing furnace?

- Box annealing furnace application: mainly used for quenching, normalizing, annealing and other conventional heat treatment equipment for steel parts. Features: 1, electric loading, high productivity, heat treatment is especially suitable for small and medium-sized parts, such as 30%, uniform temperature, intelligent digital display meter PID (pictured) automatic temperature control, high precision; 2, electric discharge loading convenient, as good; 3, door and seal the oven body is sealed automatically, without manual seal; 4, equipped with electric interlock protection device, and can prevent the fault accident due to the error. Bell type annealing furnace four bell type annealing furnace bell type annealing furnace is mainly used for annealing sheet metal in natural atmosphere and normalizing treatment of steel parts. 1, special steel, precision alloy large all fiber trolley type resistance furnace, strip, wire bright annealing. 2 、 annealing of special steel casting and forging. 3. Annealing of silicon steel sheet. 4, metal and non metal powder sintering pieces etc..

- Q: What is the price of the first grade high alumina brick?

- The specifications and different prices, relatively large fluctuations of the main push of the refractory Dongxin high alumina brick high alumina brick prices generally around 3000 have various levels of Dongxin refractories

- Q: Density of high alumina bricks

- High alumina brick by aluminum content is divided into four grades, three grade high alumina bricks content of not less than fifty-five percent, two grade high alumina bricks content of not less than 65, a high aluminum brick content of not less than 75, super high aluminium brick content above 85. As for the high aluminum brick shape, in addition to the standard high alumina brick, high alumina brick and general type, also called special high alumina brick, if the shape is very irregular it is usually called the specific type of high alumina brick, in short, to customized according to the specific use of kiln.

- Q: Can high alumina brick resist carburizing?

- Louzhu can use heavy impervious material, it is neither high alumina brick nor mullite, this product can resist seepage and have good compressive strength

- Q: What are the alloy wear resistance materials?

- According to the composition of Beijing Naimo metal materials company will wear resistant metal materials is divided into the following five categories: one: high manganese steel series: high manganese steel (ZGMn13),

- Q: What should be used as binder for making high alumina bricks?

- In addition, high alumina micro powder can be used as binding agent, or high alumina micro powder and clay powder are prepared according to a certain proportion, and synthetic mullite is used as bonding agent. With these binders, high alumina bricks without two expansion can be prepared.

Send your message to us

High Alumina Corundum and Mullite Bricks for Hot Blast Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords