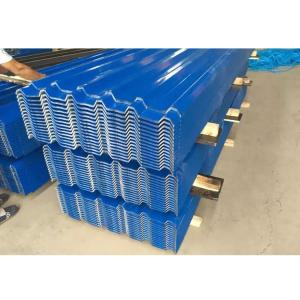

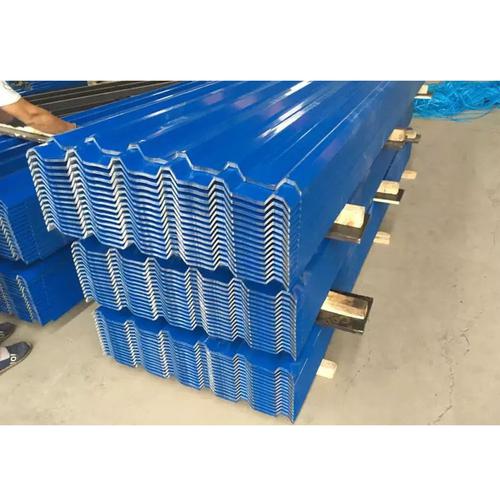

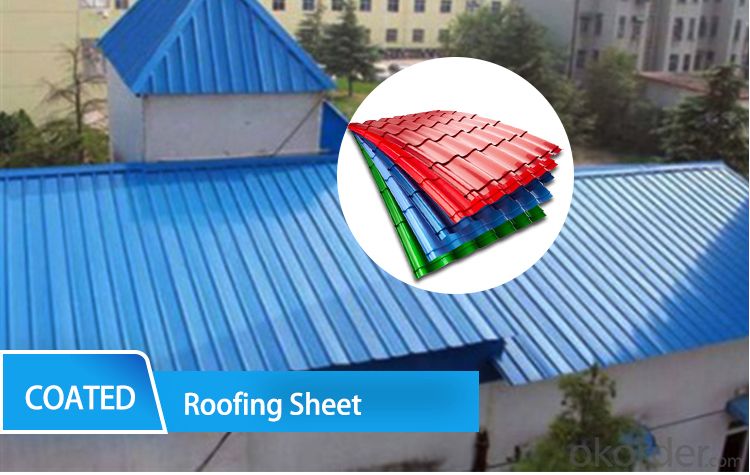

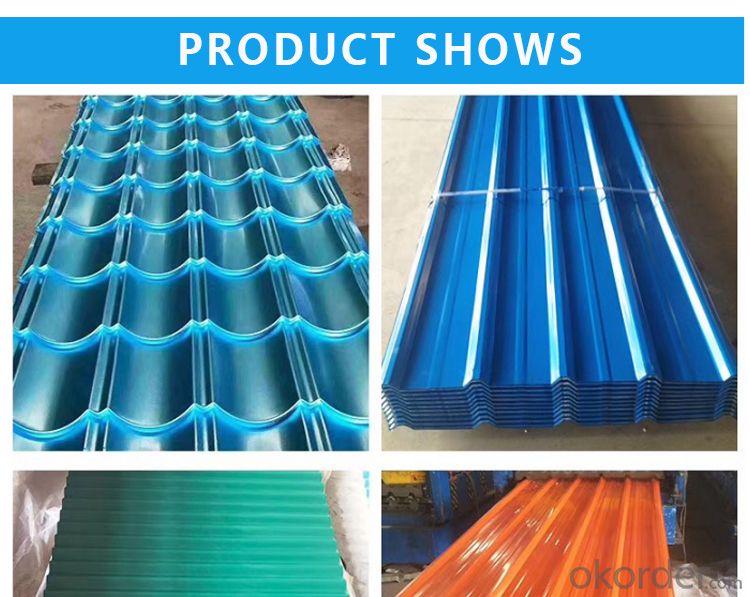

Corrugated Color Galvanized Sheet Ocean Blue Corrugated Steel Roofing Sheet PPGI Roofing Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 T

- Supply Capability:

- 5000 T/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Standard:

AISI,JIS,ASTM

Technique:

Hot Rolled,Cold Rolled

Shape:

Rectangular

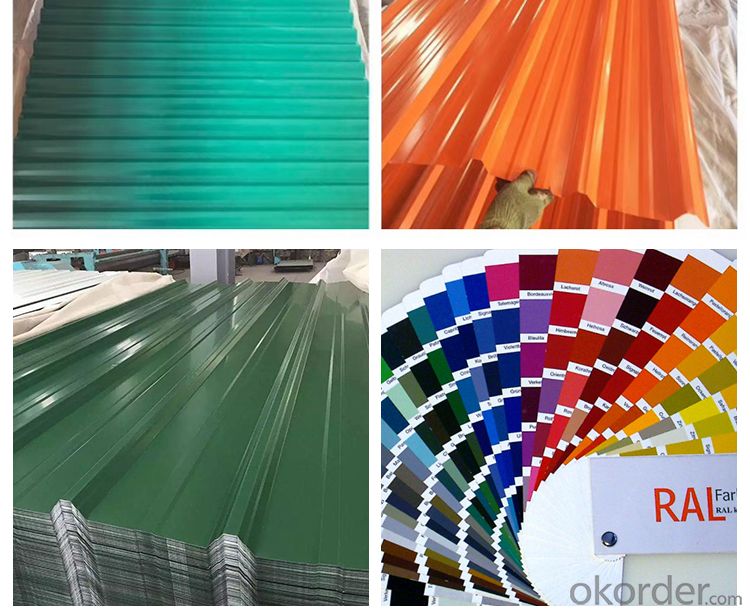

Surface Treatment:

Galvanized,Color Coated

Steel Grade:

Q195

Certification:

ISO,SGS,SNI

Thickness:

0.22-0.25mm

Width:

1221-1500mm

Length:

1400-1799mm

Net Weight:

3-5 Tons

Packaging:

Dust-proof kraft sheet、 Iron packing、 Angle protective 、Packing belt、Wood pallet

Application:

cutting sheets, making corrugated sheets

Coating:

Z121-Z180

Delivery Time:

31-45 days

Hardness:

Full Hard

Spangle Type:

Regular spangle,Minimum spangle, Zero spangle, Big spangle

Grade | DX51D, SGCC, SGCH, SGLCC, SGLCH,Q195 |

Thickness | 0.17- 0.6mm |

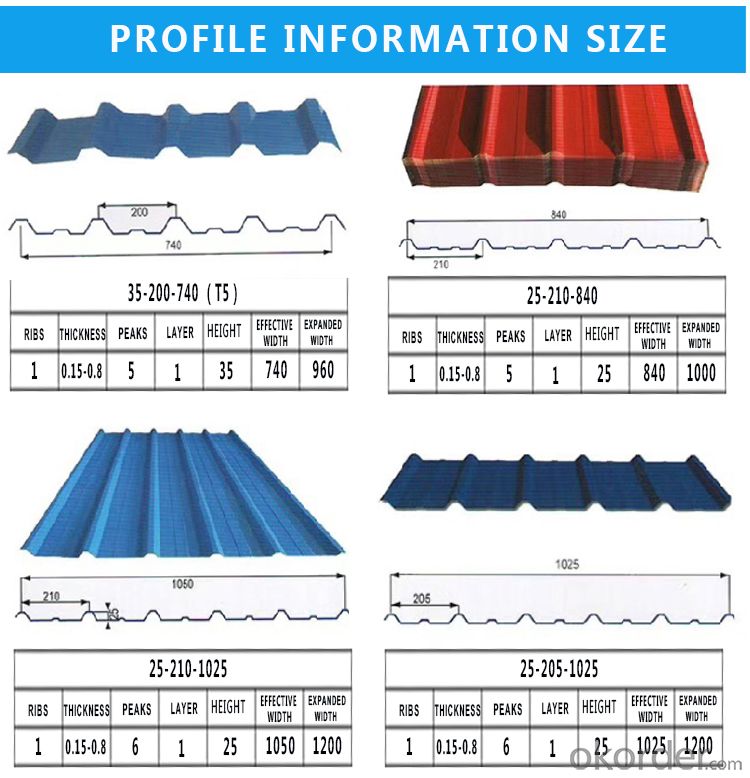

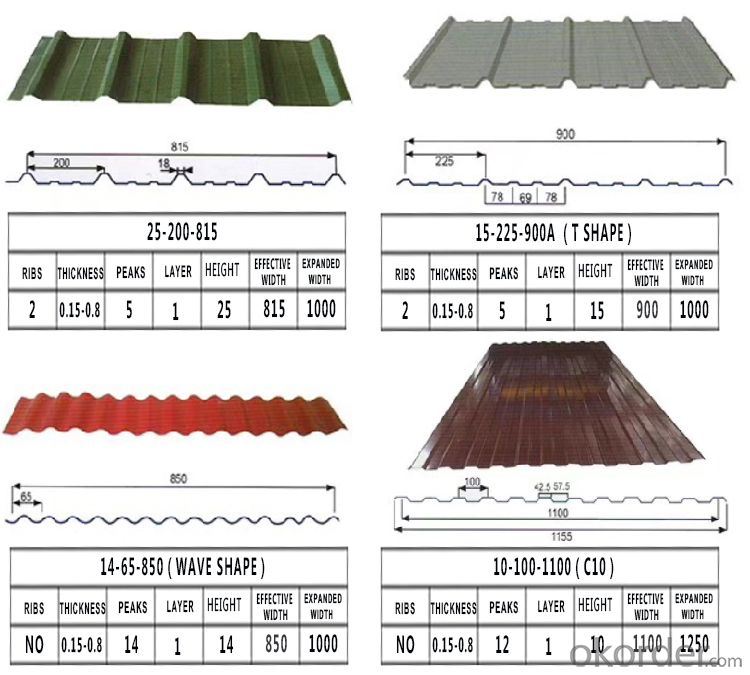

Width | 762mm/680,670,660,655,650mm 9 waves 914mm/815,810,790,780mm 11 waves 1000mm/930 915,910,905,900,880,875mm 12 or 14 waves OR OEM |

Length | 1.8- 5meters or as client’s request |

Zinc coating | 30-275g/m2 |

Coating thickness | Top side 15-25 micro; Back side 5-15 micro Normally, Top 17-25micro, Back 5-7 micro |

Surface | High Glossy |

Paints | Nippon, Akzo Nobel, Winter, Pingyuan depends on clients’ request |

- Q: How are steel coils used in various industries?

- Steel coils are used in various industries for a wide range of applications. In the automotive industry, they are used to manufacture car bodies, chassis, and parts. In construction, steel coils are used in the production of beams, columns, and roofing materials. They are also utilized in the manufacturing of appliances, electrical equipment, and machinery. Additionally, steel coils are essential in the production of pipes, tubes, and other structural components. Overall, steel coils play a crucial role in providing strength, durability, and versatility to multiple industries.

- Q: What are the different methods of cutting steel coils?

- There are several methods of cutting steel coils, including shearing, slitting, laser cutting, and saw cutting.

- Q: What are the different steel coil finishes available?

- There are several different steel coil finishes available, including hot rolled, cold rolled, galvanized, and stainless steel finishes.

- Q: How are steel coils processed for stamping or forming?

- Steel coils are processed for stamping or forming through a series of steps. First, the coils are uncoiled and straightened to remove any bends or twists. Then, they are fed into a stamping or forming machine, where the desired shape or pattern is formed by applying pressure. After the stamping or forming process, the excess material is trimmed or cut off, and the finished parts are inspected for quality.

- Q: I wanted to get a cheapo ring and I found one I like, but it's stainless steel. Is that bad? Will it get dull and tarnished fast?

- My hubby and I have some and they have stood up VERY well. He used to work with drywall, and the ring was SO easy to clean. I work with dogs and have not had a problem with my ring, either. They are heavy duty and stand up to time. LOVE them!

- Q: Can steel coils be coated with anti-graffiti materials?

- Yes, steel coils can be coated with anti-graffiti materials. These materials are designed to prevent graffiti from adhering to the surface of the steel coil, making it easier to remove any graffiti that may be applied.

- Q: If steel can rust with saltwater... then why are ships made of steel? can't we just use other metals like aluminium etc?

- Steel became the medium of construction almost be accident. The Royal Navy began to coat its wooden ships with a coating of steel to give them added protection in battle. They were known as the Iron Clads. From this it was a small step by such people as Brunnel to start construction in iron, then various other steels. The Great Eastern is a classic example. Over the last one hundred years the main improvement is in welding rather than a riveted construction. Improvements in steel have lead to a reduction in the scantlings and through this a reduction I the weight of the ship which has allowed for an increase in the carrying capacity. There always have been specialist ships built with alternative materials. Aluminium, wood, concrete and GRP. GRP. Also it must be remembered that there has been great advances in steel, from the early days of cast iron.

- Q: Hey I just got a mini 14 manufactured in 1980. I also had some .223 Wolf steel cased HP rounds (about 200) that i could shoot throught it, but I was just wondering if its a bad idea to use this steel cased ammo...? Only the casing is steel i believe... and the bullet is copper jacketedthanks for your help

- I have had significant ejection and rechambering problems with Wolf semi-auto handgun ammo. It took forever to clean the fouling that the lacquered ammo generated too. I do not know about the rifle ammo, but I won't tempt fate over cheap rounds again.

- Q: i want to know what is light gauge steel and the diffrences between light gauge steel and steel for roof truss.

- as a welder i can answere this. wel i think i can after 2 years of classes. so...light guage steel usually referes to the THICKNESS of the metal. also known as SHEET METAL. the only diffrences between light guage and roof truss is that a truss will be thicker metal ex- an i-beam for a structure is usually 1/2inch or 3/8 for smaller buildings. also there is no such thing as light weight steel. steel is steel the only thing that determins its weight is its size/thickness aluminum is a whole nother ballgame. ever see a pound of aluminum vs. a pound of steel? aluminum can be 1/2 or less the weight of steel. but its tensile strength suffers EX. say steel will snap at 70,000 pounds, aluminum will snap at 40,000 pounds, if it even snaps that is! it just tends to bend like rubber. aluminum is handy for many things because it will not rust.

- Q: How are steel coils inspected for surface defects using non-destructive testing methods?

- Steel coils are inspected for surface defects using non-destructive testing (NDT) methods to ensure their quality and integrity. There are several common NDT methods employed in this process. One of the most widely used methods is visual inspection, where trained inspectors visually examine the surface of the steel coils for any visible defects such as scratches, cracks, pits, or corrosion. This method is relatively simple and cost-effective but is limited to detecting only surface-level defects. Another commonly used NDT method is magnetic particle testing (MT). This method utilizes the principles of magnetism to identify surface and near-surface defects in ferromagnetic materials like steel. A magnetic field is applied to the steel coil, and iron particles are applied to the surface. If there is a defect, such as a crack or discontinuity, the iron particles will concentrate around it, making the defect visible to the inspector. Liquid penetrant testing (PT) is another NDT method used to inspect steel coils for surface defects. In this method, a liquid penetrant is applied to the surface of the coil. The penetrant is drawn into any surface defects by capillary action. After a certain period, excess penetrant is removed, and a developer is applied. The developer draws out the penetrant from any defects, making them visible to the inspector. Ultrasonic testing (UT) is a widely used NDT method that can detect both surface and subsurface defects in steel coils. High-frequency sound waves are transmitted into the steel coil, and the reflected waves are analyzed to identify any abnormalities. This method can detect defects such as cracks, inclusions, and voids that may not be visible to the naked eye. Additionally, eddy current testing (ECT) is another NDT method used for inspecting steel coils. This method utilizes electromagnetic induction to detect surface and near-surface defects. A coil carrying an alternating current is placed near the surface of the coil being inspected. Any changes in the coil's electrical conductivity caused by surface defects are detected and analyzed, allowing the inspector to identify and evaluate the severity of the defects. In conclusion, steel coils are inspected for surface defects using various non-destructive testing methods such as visual inspection, magnetic particle testing, liquid penetrant testing, ultrasonic testing, and eddy current testing. These methods ensure the quality and integrity of the steel coils before they are used in various applications.

Send your message to us

Corrugated Color Galvanized Sheet Ocean Blue Corrugated Steel Roofing Sheet PPGI Roofing Sheet

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 T

- Supply Capability:

- 5000 T/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Related keywords