Convenient Ring - Lock Scaffold Formwork For Industrial

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

1.convenient scaffolding system

2.industrial buildings and civil buildings

Convenient Ring - Lock Scaffold Formwork For Industrial, Civil Buildings

Description:

Brief introduction

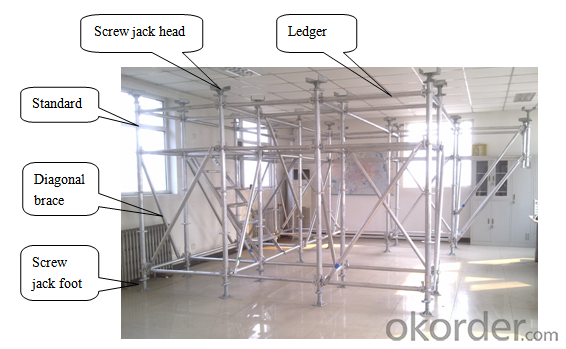

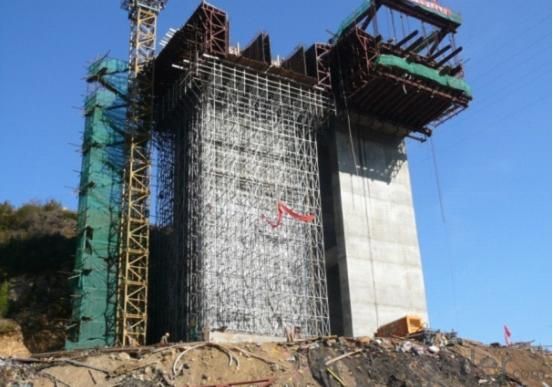

A convenient scaffolding system, especially for load-bearing support, its structure is simple and reasonable, its operation is easy and flexible, and the system is widely used in industrial buildings and civil buildings.

Competitive advantage

①. Product standardization, produce cost is lowered.

As the picture left shown, the standard is auto-welded; all the distance between cross plates of standards with different length is 500mm, which makes the auto-welded working method be easily achieved.

②. Spatial tower assembly guarantees high load-bearing capacity.

The main body of RL-scaffolding system is consisted of standard, ledger, diagonal ledger, and diagonal brace. The system forms a whole spatial frame structure that guarantees its high load-bearing capacity.

③.Smart joint design guarantees safe application and easy operation.

As the picture below shown, the “connect head” stuck in the position of cross plate with correct hole, then fix the pins tightly with a hammer, after that, you finish the whole connection work. The joint is safe and firmly.

Applications

- Q: What are the maintenance and maintenance of hydraulic climbing formwork

- Whether or not the double screw nut is used on the important bolt connection, the degree of the fastening, whether the steel bar is pressed according to the rules, and the steel wires are bundled together

- Q: Climbing frame is divided into several kinds, what is its running mode? What is the rental cost? Please explain in detail! Thank you very much

- Climbing frame installation processInstallation of platform --- display base, installation guide, assembling components - horizontal truss beam with the bolt on the guide rail, the main frame vertical rod buckle on the beam - diagonal rod buckle on the vertical rod and beam - wall installation guide device, the frame structure of unloading with elevated body, the erection of scaffolding, the laying of the intermediate layer or temporary scaffolding and temporary building structure frame of pulling and hanging outside the dense mesh safety net - loaded third beams to guide seat -

- Q: The difference between the scaffold and the scaffold

- The climbing frame is the kind of iron that is assembled by a large construction site

- Q: Advantages and disadvantages of climbing frame and floor type scaffold

- Floor scaffold:Advantage:1) large bearing capacity. When the scaffolding geometry and structure comply with the relevant requirements, under normal circumstances, the bearing capacity of 15kN ~ 35kN of the single column scaffold (1.5tf ~ 3.5tf, design value).

- Q: The whole concrete wall climbing frame or good use of steel scaffolding

- Floor scaffold:Advantage:1) large bearing capacity. When the scaffolding geometry and structure comply with the relevant requirements, under normal circumstances, the bearing capacity of 15kN ~ 35kN of the single column scaffold (1.5tf ~ 3.5tf, design value).Clamp and Tube Scaffold2) easy to install and disassemble, set up flexible. Because the length of the steel tube is easy to adjust and the fastener is convenient to connect, the utility model can be used for various buildings and structures with various planes and elevations.3, compared with the economy, the processing is simple, and the investment cost is low; if the geometric dimensions of the scaffold are carefully designed, and the utilization rate of the steel tube is improved, the material consumption can also obtain better economic effect. Fastener steel pipe frame equivalent to 15 square meters per square meter of construction steel.

- Q: What is an integrated climbing frame? What are the works? What are the advantages

- The climbing frame, which is also called the lifting frame, can be divided into several types, such as hydraulic, electric, manual and so on. It is a new type of scaffolding system developed in recent years, which is mainly used in high-rise shear wall construction.

Send your message to us

Convenient Ring - Lock Scaffold Formwork For Industrial

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords