Construction and Mining Used Ductile Iron Manhole Cover

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Features

1.High Intensity

It adopts macromolecule complex material and reinforcing steel bar moulded by high temperature and press at one time.

2.Durable

Acid-alkali and corrosion resistance; anti-rust; insulation; weatherability; excellent anti-pressure capability.

3.Unique appearance

Rich colors;the cover is not sprayed in surface but painted in whole material so that the color can keep lasted.

4.Competitive price

The price of compound manhole cover is lower than stipulated standard cast iron ones.

5.Save mine resource

It is made by regenerated resin or regenerated plastic raw material, which save application of cast iron.

Packaging and Shipping

Delivery Detail: 8 days if your order is 20"container

Packaging: Details Pallet with bubble film, Carton or with pallet

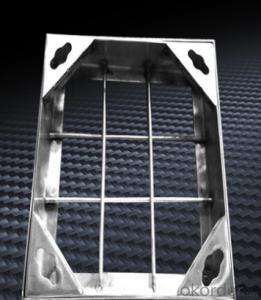

Pictures

Advantage of ductile iron

Higher quality /higher tensile

Higher security /long life

Our Company

We take pride to introduce ourselves as the leading manufacturer and professional supplier of various Ductile Iron Manhole covers in China with total annual capacity 50,000 MT.

CNBM manhole cover regard quality as the essential factor leading to successful business. After years of efforts, CNBM manhole cover have built up great reputation in terms of quality and service among domestic and overseas customers.

Our Services

1. Sample is available for free.

2. OEM and ODM are welcome.

3. Free charge of design labels and cartons.

4. Professional technical support with free charge.

5. After the cooperation: Any of your problem will be solved within 24 hours.

- Q: Casting blank in the cooling process to release a large amount of heat energy, what can be recycled?

- Casting, do not need to provide a rough casting foundry drawings, according to your chart will put foot margin in the processing needs of the surface, the rest of the size can be found according to the mechanical design manual and manual casting. General Casting Factory Casting Division will be in your chart marked on shrinkage and processing margin figure (usually with red and green pen) to the patternmaker production of wood or other material mould diagram.

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- According to the requirements of the workpiece annealing, there are many kinds of annealing process specifications, such as full annealing, spheroidizing annealing and stress relieving annealing. Steel the steel quenching is heated to the critical temperature Ac3 (hyposteel) or Ac1 (hypereutectoid steel) above a certain temperature, holding time, so that all or part of 1 Austenitic, then the cooling rate is greater than the critical cooling rate of fast cooling to below Ms (or near Ms isothermal) of martensite the body (or bainite transformation) heat treatment process. Aluminum alloys, copper alloys, titanium alloys, tempered glass and other materials are usually treated by solid solution or heat treatment with rapid cooling process. Tempering is a heat treatment process where the workpiece is hardened and heated to a temperature below AC1, which remains cool for a certain period of time and then cools to room temperature. Tempering generally followed by quenching, the purpose is: (a) to eliminate the residual stress caused by quenching, prevent deformation and cracking; (b) hardness, strength, plasticity and toughness of workpiece is adjusted, to use performance requirements; (c) the size of organization and stability, ensure the accuracy improvement; (D) and to improve the processing performance. Tempering is therefore the last important step in obtaining the desired properties of the workpiece. According to the tempering temperature range, tempering can be divided into low temperature tempering, medium temperature tempering and high temperature tempering. This answer is recommended by the questioner

- Q: The casting defects of pores, trachoma how to repair?

- Airhole above 2mm recommended LT101 casting defect repair agent. If repair quality requirements, high availability LT111 iron repair agent, LT112 steel repair agent, LT113 aluminum repair agent, LT114 copper repair agent.

- Q: Casting parts need to be subjected to the kind of heat treatment after the weldment is finished

- This is difficult to say, the key is to see the specific parts and components, the final mechanical performance requirements.For example, gray cast iron, usually graphite annealing, to heat treatment annealing, surface quenching and so on, ductile iron can be a variety of annealing, normalizing, quenching and isothermal quenching, surface treatment, chemical treatment and so on, in a word, heat treatment of steel can usually, nodular cast iron can do. Malleable cast iron and vermicular cast iron are often subjected to graphitization annealing and stress relieving annealing, while wear-resistant cast irons often undergo quenching + low temperature tempering, and so on.Welding is the case, such as bearing steel welding must be quenched + low temperature tempering, machine spindle welding (repair welding) must be quenched and tempered treatment, and so on. Of course, if it is a general weld, there is no need for heat treatment or, at most, stress relieving annealing.

- Q: What are the effects of stiffeners on castings, or on welded parts (for 2 tons or less), casting or weldments on stiffeners?

- 3, weight: if reinforcement in products, casting weight is generally greater than the welding parts (the internal organizational structure and mode of production determines the mechanical properties of materials, so it determines the weight of the product), considering the cost of transportation, certain priority structure.

- Q: Why do casting parts have air holes?

- Cangshan Qiao hidden his answer is quite comprehensive, you can try using inert gas to reduce air cover

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- The choice of shot blasting machine, this is according to the workpiece size, yield, whether can collision, and the working time and other factors considered, while the price of different blasting machine are not the same, but the vast majority of small castings used crawler shot blasting machine,

- Q: My parts complex, machining costs are relatively high, so want to cast, but the surface needs anodizing, what material will be better?

- The common material that can be anodized is aluminum alloy. It is recommended to use casting aluminum alloys, such as ZL102 and ZL105, which are commonly used as cast aluminium alloys. The processing of aluminum casting is easy. After processing, the surface of the whole part can be anodized. The color can be chosen.

- Q: In the design of casting steps and precautions, for casting design, we have what experience?.

- Two: the basic structure unit in the design of metal casting type and the parameters selected, usually should also pay attention to: (1) because of the metal type heat quickly, so the metal type casting minimum wall thickness should be bigger than the sand casting, metal type casting alloy minimum wall, different size of castings see table 1.1-31 thick can be selected; (2) the inner wall of the casting internal ribs and the thickness of wall thickness should be 0.6-0.7 connected, or as the inner wall (rib) cold slowly, cracks in the wall at the junction in the casting shrinkage;

- Q: ZGMn13 casting parts processing, with what knife head good?

- its surface wear resistance is high; the two is with the gradual wear of surface hardening, the hardening layer is continuously formed new if you have suggestions, processing, plasma cutting or flame cutting try

Send your message to us

Construction and Mining Used Ductile Iron Manhole Cover

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 set

- Supply Capability:

- 4000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches