Concrete Pump Truck Parts Elbow Bend R275 DN125 148Flange 15DGR Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 180 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Main Product Features:

1. High Chromium and manganese content, which enables a higher wear resisting ability and longer lifetime.

2. Service life: 55000-150000 CBM Concrete.

3. Possess quality certification of ISO 9001:2000.

4. A wide range of specifications for you./ We have been providing parts for nearly ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market.

5. We can supply OEM service and can also produce according to your requirements.

6. Total series of concrete pump ELBOW for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

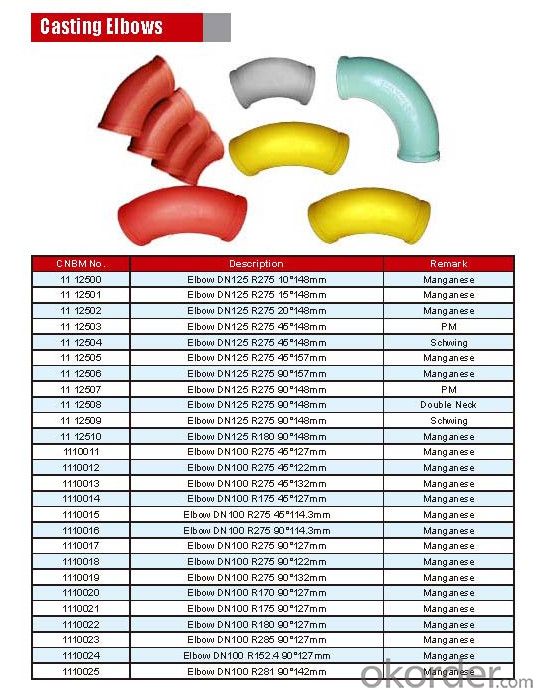

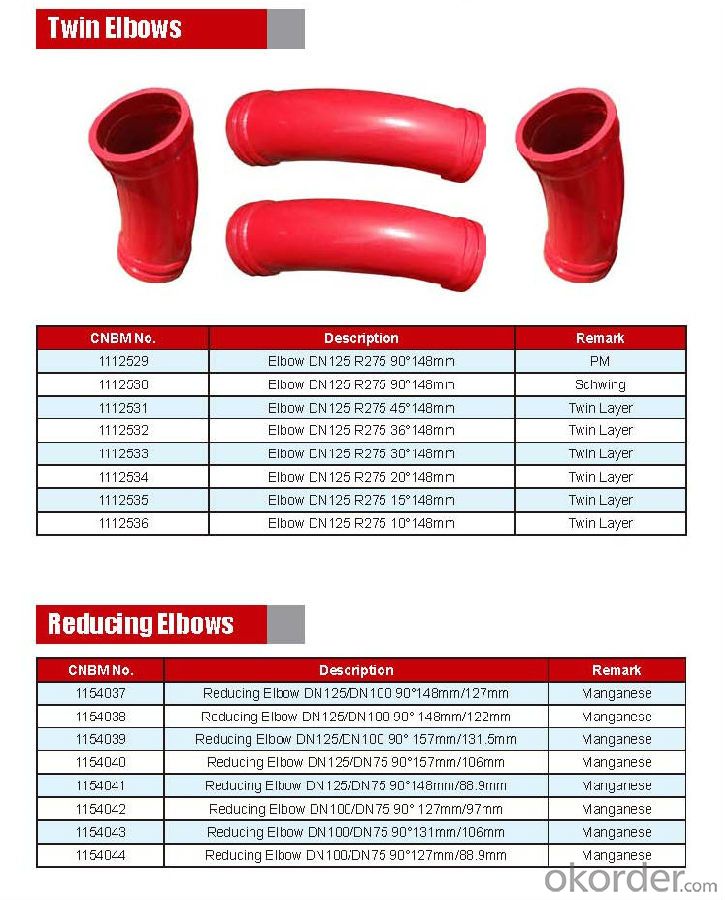

Product Specifications:

Technology: Cast

Dimension: DN125

Radius: 275mm

Degree: 15D

Material: Mn13-4

Weight: 4.8kg

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: Every 180pcs put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: How to confirm that your elbows could be used in our pump?

A1: We have been providing parts for nearly ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market. What is more, we can produce as the customers request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 20 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: How can a faulty filter affect the pumping process?

- The pumping process can be significantly affected by a faulty filter in various ways. To begin with, the flow of fluid through the pump may be hindered if the filter becomes clogged or blocked. This can lead to reduced efficiency and increased energy consumption as the pump must exert more effort to overcome the resistance caused by the obstructed filter. Additionally, the decreased flow rate can result in longer pumping times, which can be problematic in time-sensitive applications. Moreover, a faulty filter may not effectively eliminate impurities or contaminants from the fluid being pumped. This can be particularly troublesome in industries where maintaining the purity or cleanliness of the fluid is crucial, such as in pharmaceutical or food processing applications. The presence of contaminants can jeopardize the quality of the final product or cause damage to equipment downstream from the pump. Furthermore, increased maintenance and repair costs can be a consequence of a faulty filter. If the filter is not functioning properly, it may allow larger particles or debris to pass through, which can cause damage to the pump components. This can result in heightened wear and tear, a shorter lifespan for the pump, and the need for more frequent repairs or replacements. Finally, a faulty filter can pose a risk to the overall system and its components. Complete failure of the filter can allow foreign objects or particles to enter the pump, potentially leading to blockages, damage to internal components, or even total pump failure. This can result in costly downtime, loss of production, and the need for emergency repairs or replacements. In conclusion, a faulty filter can have negative effects on the pumping process, including decreased efficiency, compromised fluid quality, increased maintenance costs, and potential damage to the pump and system components. Regular inspection, maintenance, and timely replacement of filters are crucial to ensure smooth and reliable operation of pumps in various industries.

- Q: What is the concrete delivery pump?

- Concrete pump, also called concrete pump, consists of pump body and pipe

- Q: How does a hopper vibrator prevent concrete blockages?

- A hopper vibrator is a mechanical device designed to prevent concrete blockages in construction equipment, such as concrete pumps and mixers. It works by applying vibrations to the hopper, which is the large container where the concrete is stored before it is poured or transferred. The main reason concrete blockages occur is due to the tendency of the material to settle and become compacted, especially when it is stored for a long time or during transportation. This can lead to clogging and obstruction of the flow of concrete, slowing down the construction process and potentially causing damage to the equipment. By using a hopper vibrator, the vibrations are transmitted to the concrete within the hopper, effectively preventing it from settling and compacting. The vibrations create a loosening effect on the concrete particles, ensuring that they remain in a more fluid state. This allows for a continuous and smooth flow of concrete, preventing any blockages or obstructions from occurring. Additionally, the vibrations from the hopper vibrator also help to dislodge any potential blockages that may have already formed. The shaking motion can break up clumps of concrete or other debris that might be blocking the flow, allowing for uninterrupted movement of the material. Overall, a hopper vibrator is an essential tool in construction equipment as it helps to maintain a consistent flow of concrete, preventing blockages and ensuring the smooth and efficient operation of the construction process.

- Q: What are the causes of pipe blockage in concrete pump?

- In theory, plugging is most likely to occur when 3 large stones meet at the same cross section. When the section is occupied by pebbles, the circulation area is very small

- Q: What are the indications of a faulty concrete pump hydraulic motor?

- There are several signs that can indicate a malfunctioning hydraulic motor in a concrete pump. Some common indicators to watch for are: 1. Power loss: If the hydraulic motor is not working correctly, you may notice a significant decrease in power in the concrete pump. The motor may struggle to generate enough force to effectively pump the concrete, resulting in slower or weaker output. 2. Unusual noises or vibrations: A faulty hydraulic motor may produce abnormal sounds or vibrations while in operation. This could be due to damaged internal components or misalignment, indicating an issue with the motor. 3. Leaking fluids: Proper flow and pressure of hydraulic fluid are essential for the functioning of hydraulic motors. If you observe any fluid leaks around the hydraulic motor or its associated parts, it could be a sign of a faulty motor that requires attention. 4. Overheating: A malfunctioning hydraulic motor may overheat due to increased friction or internal problems. If you notice excessive heat emanating from the motor or its associated parts, it is crucial to address the problem promptly to prevent further damage. 5. Inconsistent or jerky movement: A faulty hydraulic motor can cause the concrete pump to operate unevenly or jerkily. This can result in uneven pouring or difficulty in controlling the flow of concrete, indicating an issue with the motor's performance. 6. Increased energy consumption: A faulty hydraulic motor may consume more energy to function properly. This can lead to a noticeable rise in energy usage, which can be observed through higher electricity bills or added strain on other components of the pump's system. It is important to remember that these signs may vary depending on the specific make and model of the concrete pump hydraulic motor. It is always recommended to consult the manufacturer's guidelines or seek professional assistance to effectively diagnose and address any issues with the hydraulic motor.

- Q: How often should hydraulic filters be replaced in a concrete pump?

- To ensure optimal performance and longevity of the equipment, it is important to regularly replace the hydraulic filters in a concrete pump. The frequency of replacement will depend on factors such as the specific model of the concrete pump, the operating conditions, and the quality of hydraulic fluid used. As a general rule, it is recommended to replace the hydraulic filters every 500 to 1,000 operating hours or at least once a year, whichever comes first. However, it is crucial to consult the manufacturer's recommendations and guidelines for the specific model of the concrete pump, as they may have specific maintenance schedules and intervals. Regularly inspecting the hydraulic filters is also vital to determine if replacement is necessary before the recommended interval. If the filters are clogged, damaged, or show signs of excessive wear, immediate replacement is necessary to prevent potential damage to the hydraulic system. Additionally, if the concrete pump operates in harsh or dusty environments, more frequent filter replacements may be required to ensure proper filtration and prevent contamination. In conclusion, timely and proper replacement of hydraulic filters in a concrete pump is crucial to maintain efficiency and reliability, prevent breakdowns, and prolong the service life of the equipment.

- Q: How long does a concrete pump piston typically last?

- A concrete pump piston typically lasts between 20,000 to 60,000 pumping hours, depending on factors such as maintenance, usage, and the quality of the pump.

- Q: Are there any warranties or guarantees available for concrete pump spare parts?

- Yes, there are warranties and guarantees available for concrete pump spare parts. Many reputable manufacturers and suppliers offer warranties on their products, providing assurance of quality and performance. These warranties typically cover defects in materials or workmanship and may vary in duration and terms. It is advisable to inquire about the specific warranty or guarantee offered by the supplier before purchasing concrete pump spare parts.

- Q: How do I properly maintain and replace rubber pistons in concrete pump spare parts?

- Proper maintenance and replacement of rubber pistons in concrete pump spare parts involves a few key steps. Firstly, make sure to regularly inspect the pistons for any signs of wear, such as cracks or tears. It is recommended to replace them if they are significantly worn or damaged. To replace the rubber pistons, start by removing the old piston carefully, ensuring not to damage the cylinder or any other components. Clean the cylinder thoroughly, removing any debris or residue. Apply a lubricant or concrete pump primer to the cylinder walls to aid in the installation of the new piston. Next, carefully install the new rubber piston, ensuring it is properly aligned with the cylinder. Gently push it into place, avoiding any unnecessary force that could cause damage. It is important to refer to the manufacturer's instructions or guidelines for specific installation techniques. After replacing the rubber piston, run a few tests to ensure its proper functioning. Check for proper sealing and smooth operation by conducting a dry run or pumping a small amount of concrete. Monitor the piston's performance closely, and if any issues arise, consult a professional or the manufacturer for further guidance. Regular maintenance, such as cleaning the cylinder and lubricating the pistons, can help extend their lifespan. Additionally, following proper operating procedures, such as avoiding excessive pressure or abrasive materials, can also contribute to the longevity of rubber pistons.

- Q: How long do concrete pump spare parts typically last?

- The lifespan of concrete pump spare parts can vary depending on several factors. Generally, high-quality spare parts can last anywhere between 1,000 to 2,500 working hours. However, this estimate is influenced by factors such as the type and brand of the spare parts, the frequency of use, the quality of maintenance, and the working conditions in which the concrete pump operates. Some concrete pump spare parts may have a shorter lifespan due to the wear and tear they experience during operation. For instance, wear parts like rubber seals, pistons, and wear plates are more susceptible to damage and may need to be replaced more frequently. On the other hand, structural components like pipes, hoses, and hydraulic cylinders tend to have a longer lifespan. Proper maintenance and regular inspections play a crucial role in extending the lifespan of concrete pump spare parts. Adequate lubrication, cleaning, and timely replacement of worn-out parts can significantly enhance their durability. Additionally, the expertise and skill of the operator also influence the lifespan of the spare parts since improper use or mishandling can lead to premature failure. Overall, while the average lifespan of concrete pump spare parts can be estimated, it is important to consider the specific circumstances and conditions in which the concrete pump operates to determine their actual longevity. Regular maintenance, high-quality parts, and proper usage will ultimately contribute to maximizing the lifespan of concrete pump spare parts.

Send your message to us

Concrete Pump Truck Parts Elbow Bend R275 DN125 148Flange 15DGR Casting

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 180 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords