Concrete Pump Truck Parts Elbow Bend R275 DN112 148Flange 45DGR Casting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 140 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Widely used on concrete pump truck, concrete placing boom, trailer concrete pump etc, for concrete delivery pipe connection.

Our concrete pump bends have been successfully exported to many countries from 1998, Our main markets as below: Middle East, Southeast Asia, America, Brazil, Italy, Russia, South Africa etc

Main Product Features:

1. Mainly adopt carbon steel high wear resistant steel, and other material upon your request. Adopt the new plasma quenching and chromium plating process, which increases the concrete conveying life and reduces the frequency of replacement, saving the cost for the customers.

2. Service life: 55000-150000 CBM Concrete. The inner side of this concrete pump elbow undergoes heat treatment, and then the hardness can reach 68HRC.

3. Possess quality certification of ISO 9001:2000. Can pass CE test.

4. We have been providing parts for nearly ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market.

5. We can supply OEM service and can also produce according to your requirements.

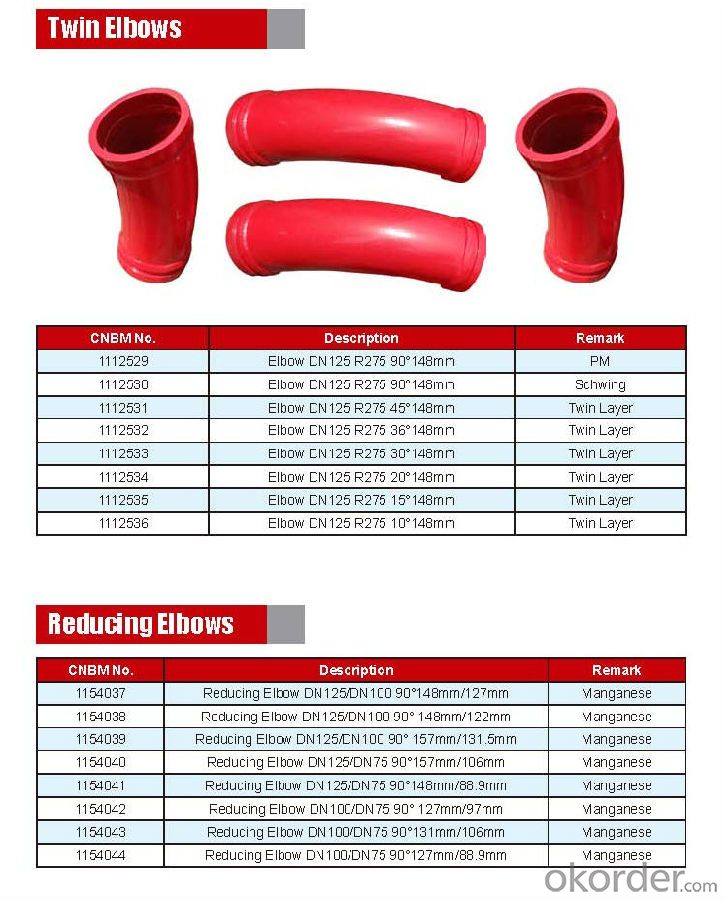

6. Total series of concrete pump ELBOW for different brand concrete pump(PUTZMEISTER, SCHWING, CIFA, SANY, ZOOMLION, IHI, KYOKUTO Etc) available from us.

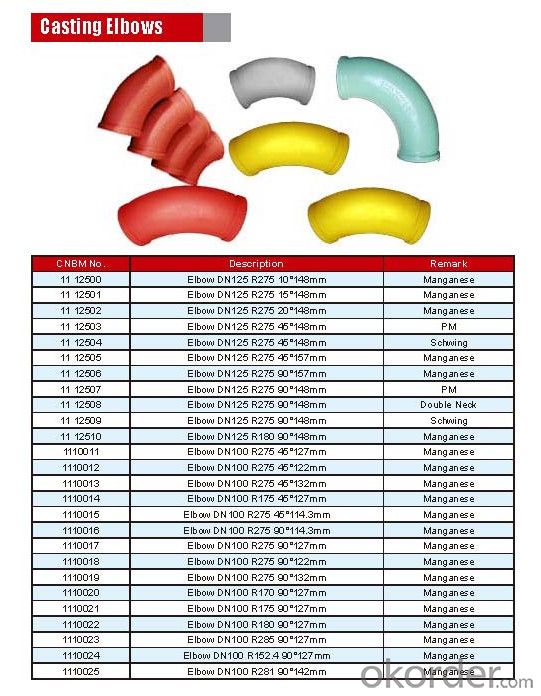

Product Specifications:

Technology: Cast

Dimension: DN112

Radius: 275mm

Degree: 45D

Material: Mn13-4

Characteristics: According to our technology, the cast elbow also has high working pressure and burst pressure.

Package: Every 140pcs put in one seaworthy wooden box, and 20 boxes in one 20feet container.

FAQ:

Q1: How to confirm that your elbows could be used in our pump?

A1: We have been providing parts for more than ten years, and cooperting with the agent of the world famous brand, possess near every kind of elbow in the market. What is more, we can produce as the customers request with drawing provided.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 10 to 20 workdays.

Q4: If we can produce some Concrete Pump Truck Parts according to customers request?

A4: Yes, we can produce Concrete Pump Truck Parts according to the difference country situations to make it suitable to the market and customers. We have very professional technical team to make the design.

Q5: How to make a quick resolution for after service?

A5: OKorder and our manufacture both have overseas branches all-around of world, IF needed, the seller shall dispatch 2 engineers to the buyer's site for supervision of training. The buyer shall make available of necessary facilities & skilled personnel at site for training.

- Q: Are there any special tools required for replacing concrete pump spare parts?

- Yes, there are special tools required for replacing concrete pump spare parts. These tools may include wrenches, screwdrivers, hydraulic jacks, cranes or hoists, and specific equipment for removing and installing components such as seals, bearings, or pistons. Additionally, some specialized tasks may require the use of a welding machine or cutting tools. It is important to have the right tools to ensure a safe and efficient replacement process.

- Q: Can a concrete pump wear plate be repaired or does it need to be replaced entirely?

- In certain situations, a concrete pump wear plate may require repair or complete replacement. The determination of whether to repair or replace the wear plate depends on the extent of the damage and the overall condition of the plate. In the case of minor damages such as small cracks, dents, or worn out areas, suitable techniques can often be employed for repair. For instance, small cracks can be welded or filled with an appropriate epoxy or filler material. Similarly, dents or worn out areas can be filled and smoothed to restore the plate's functionality. However, if the wear plate has sustained significant damage, such as extensive cracks, severe corrosion, or large holes, it may be more advisable to replace the plate entirely. This is due to the potential compromise in the structural integrity and effectiveness of the wear plate if extensive damage is repaired. Optimal performance and safety of the concrete pump can be ensured by replacing the wear plate in these cases. Careful assessment of the wear plate's condition is crucial before deciding to repair or replace it. Seeking guidance from experts or professionals knowledgeable in concrete pump maintenance can provide valuable insights in making the appropriate decision. Additionally, regular maintenance and inspection of the wear plate can help detect potential issues early on, enabling timely repairs or replacements to prevent further damage and ensure the efficient operation of the concrete pump.

- Q: What are the common signs of wear and tear on concrete pump spare parts?

- The common signs of wear and tear on concrete pump spare parts can vary depending on the specific part in question. However, there are some general signs that can indicate when a concrete pump spare part is experiencing wear and tear. One common sign is visible damage or deterioration on the surface of the part. This can include cracks, chips, or dents on the outer layer of the spare part. These damages can occur due to regular use, exposure to harsh environmental conditions, or accidental impact during operation. Another sign is increased vibration or noise during operation. If a concrete pump spare part is experiencing wear and tear, it may start to produce unusual vibrations or noises that were not present when it was in good condition. This can be an indicator of internal damage or misalignment of the part, which can affect its overall performance and efficiency. Reduced performance or efficiency is also a common sign of wear and tear on concrete pump spare parts. If a part is experiencing wear and tear, it may not function as effectively as before, resulting in decreased pumping capacity, reduced flow rate, or inefficient operation. This can lead to delays in construction projects and increased maintenance costs. Additionally, increased maintenance and repair requirements can indicate wear and tear on concrete pump spare parts. If a part needs to be repaired or replaced more frequently than usual, it could be a sign that it is experiencing wear and tear. Regular inspections and maintenance can help identify potential issues early on and prevent further damage to the spare parts. In conclusion, signs of wear and tear on concrete pump spare parts can include visible damage, increased vibration or noise during operation, reduced performance or efficiency, and increased maintenance requirements. It is important to regularly inspect and maintain these spare parts to ensure their optimal performance and prolong their lifespan.

- Q: Can I get spare parts for concrete pump hopper agitators and vibrators?

- Yes, you can get spare parts for concrete pump hopper agitators and vibrators.

- Q: How often should a hopper filter be cleaned or replaced?

- The frequency at which a hopper filter should be cleaned or replaced depends on various factors such as the type of hopper, the nature of contaminants, and the usage pattern. As a general guideline, it is recommended to clean or replace the hopper filter at least once every three to six months. However, if the hopper is used in a particularly dusty or dirty environment, or if it handles materials that produce a high level of debris, more frequent cleaning or replacement may be necessary. Regular inspection of the hopper filter is crucial to determine the accumulation of particles and the effectiveness of filtration. Additionally, if the hopper filter starts to show signs of damage or wear, it should be replaced immediately to maintain optimal performance and prevent any potential contamination. Ultimately, it is advisable to refer to the manufacturer's guidelines and recommendations for the specific hopper filter being used.

- Q: How often should concrete pump remote control antennas be inspected and replaced?

- Concrete pump remote control antennas should be inspected regularly, preferably on a monthly basis, to ensure they are in good working condition. However, the frequency of replacement depends on several factors such as usage, environmental conditions, and wear and tear. It is recommended to replace the antennas if they are damaged, show signs of malfunction, or if there is a noticeable decrease in signal strength.

- Q: What is the function of a concrete pump remote control?

- The concrete pump remote control is a tool that enables the operation and control of a concrete pump from a distance. It grants the operator the ability to manipulate various aspects of the pump's functioning, including initiating and terminating the pumping process, adjusting the pump's speed and direction, and governing the placement and flow of the concrete. Through its capacity for remote control, it eliminates the necessity for the operator to be in close physical proximity to the pump, thereby enabling a safer and more efficient operation. Furthermore, the remote control frequently incorporates additional features, such as emergency stop buttons, diagnostics, and data logging capabilities, which further augment the functionality and dependability of the concrete pump. In summary, the concrete pump remote control serves to provide convenience, accuracy, and safety in the operation of concrete pumping equipment.

- Q: How can one source reliable suppliers for concrete pump spare parts?

- To find reliable suppliers for concrete pump spare parts, several steps can be taken. Firstly, conducting comprehensive research on potential suppliers is crucial. This involves searching online directories, industry forums, and construction equipment and spare parts marketplaces. Valuable insights into the reliability and quality of the suppliers can be gained by reading customer reviews and ratings. Secondly, seeking advice and recommendations from experienced industry professionals and experts in the concrete pump industry is advisable. They can provide references for reliable suppliers they have previously worked with. Attending trade shows and exhibitions related to the construction industry is also a beneficial way to connect with suppliers and evaluate their product offerings in person. This allows for direct communication and the opportunity to assess the reliability and quality of their spare parts. Additionally, requesting samples or product catalogs from potential suppliers is essential to ensure that the spare parts meet the required specifications and quality standards. This helps in assessing the reliability of the suppliers and the compatibility of their products with the concrete pump. Furthermore, conducting background checks on the suppliers is crucial. Verifying their credentials, certifications, and licenses provides assurance of their reliability and professionalism. Inquiring about their manufacturing processes and quality control measures is also beneficial to ensure the consistency and durability of the spare parts. Lastly, comparing prices, warranties, and after-sales services offered by different suppliers aids in making an informed decision. Striking a balance between cost and reliability is important to establish a long-term and fruitful partnership. By following these steps and thoroughly evaluating and researching potential suppliers, reliable suppliers for concrete pump spare parts can be sourced. This ensures the smooth operation and maintenance of equipment.

- Q: What is the function of a concrete pump hydraulic motor?

- The concrete pump hydraulic motor serves the purpose of supplying the essential power and force needed for the operation of the concrete pump. Its responsibility lies in transforming hydraulic energy into mechanical energy, thereby enabling the pump to function with efficiency and effectiveness. By propelling the pumping mechanism, it allows the concrete to be transported through the pipeline and delivered to the desired destination. Additionally, the hydraulic motor governs the pump's speed and direction, facilitating accurate placement of the concrete. In conclusion, the concrete pump hydraulic motor plays a vital role in guaranteeing the seamless operation and triumphant delivery of concrete in construction endeavors.

- Q: What is the importance of a concrete pump control valve?

- The operation of a concrete pump heavily relies on the presence of a control valve, which plays a vital role. This crucial component allows for the accurate and efficient management of concrete flow and pressure. To grasp the significance of a concrete pump control valve, one must consider its various functions. Firstly, it serves to regulate the movement of concrete from the hopper to the pumping cylinders. Through manipulation of this valve, operators can adjust the flow rate to meet the specific demands of the project. This ensures that the appropriate amount of concrete is pumped, preventing wastage and optimizing productivity. Secondly, the control valve facilitates precise control of pressure within the pumping cylinders. By making adjustments to the valve, operators can increase or decrease pressure levels, maintaining a consistent and steady concrete flow. This ability is crucial in preventing blockages or clogs within the concrete pump system, which can lead to costly downtime and repairs. Moreover, the control valve enables operators to switch between different pumping modes, such as high-pressure pumping or low-pressure spraying. This versatility allows for the efficient completion of a wide range of concrete pumping tasks, from pouring foundations to applying decorative concrete finishes. In addition to its functional significance, a concrete pump control valve also contributes to the safety of the pumping operation. It empowers operators to halt or reverse the flow of concrete swiftly in the event of emergencies or equipment malfunctions. This feature ensures that potential hazards are promptly addressed, minimizing the risk of accidents and injuries. Overall, the importance of a concrete pump control valve lies in its capacity to provide precise control over concrete flow and pressure during pumping operations. It guarantees efficiency, productivity, versatility, and safety, establishing it as an indispensable component of any concrete pumping system.

Send your message to us

Concrete Pump Truck Parts Elbow Bend R275 DN112 148Flange 45DGR Casting

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 140 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords