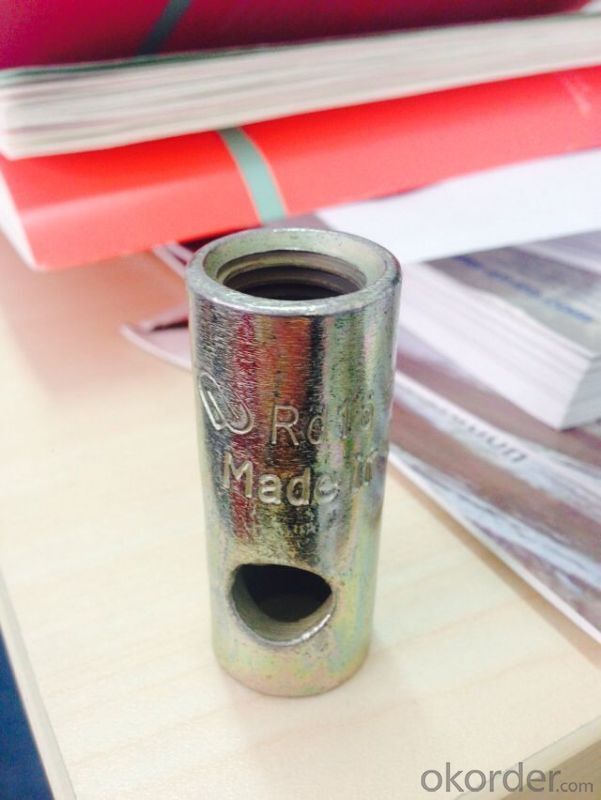

Concrete Lifting Socket for Constrcution Useing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Concrete lifting socket for construction hardware

Specifications:

1) Diameter: M/RD 12 - 36mm

2) Length: 40 - 200mm

3) Capacity: 0.5 - 12.5MT

4) Material: stainless 304/316, ST52.3

5) Surface: plain, galvanized

Thread M/RD 12-52 lifting socket

Testing before shipment

Provide test certificate

Products available: lifting socket,lifting insert, bend and waved socket, transport socket, flat socket, socket with bar and more

2.Packaging and delivery:

Packaging details: goods packed in cartons and then on the pallete

Delivery lead time: within 25 days after getting payment

3.Primary competitive advantages:

1)More than 10 years focus on building material manufacturing

2)On-time delivery within 25 days after confirming order

3)Eathu’s products are enhanced by the QA and quality control checks during the production, if necessary each order can be send out with a certificate referring back to test

4)Precast concrete elements may be lifted several times after casting and during storage and erection-by using this system, the designer and the worker manager ensure that each lift is carried out safely and quickly

· Product Performance

· Prompt Delivery

· Quality Approvals

· Reputation

· Service

· Small Orders Accepted

· Experienced Staff

· Form A

· Guarantee/Warranty

· Packaging

· Price

· Product Features

· More Than 10 Years Experience

· Testing before Shipment

Market:

Asia

Australasia

Central/South America

Mid East/Africa

North America

Western Europe

FAQ:

Q1: How long about delivery time Concrete Lifting Socket ?

A1: The delivery time will be very short, normally we keep the raw materials for old customers and sometime we also keep stock products to

make sure delivery time in any emergency cases.

Q2: How do we guarantee the quality of our Concrete lifting socket?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will book the vessel for goods. The specific shipping date is dependent upon international and government factors, but is typically 7 to 30 workdays.

- Q: What are the potential risks of using non-standard or modified hydraulic components in concrete pump spare parts?

- There are several potential risks associated with using non-standard or modified hydraulic components in concrete pump spare parts. Firstly, these components may not have undergone the same rigorous testing and quality control as the original equipment manufacturer (OEM) parts. As a result, their performance and durability may be compromised, which can lead to potential failures or malfunctions. This, in turn, can cause accidents, injuries, or damage to the equipment or surrounding structures. Secondly, the use of non-standard or modified components may void the warranty of the concrete pump and its spare parts. Typically, manufacturers offer warranties to ensure the reliability and safety of their products. However, by using non-standard components, the warranty may become null and void. Consequently, the user will be responsible for any repairs or replacements needed due to issues arising from these non-standard parts. Another risk is the potential compatibility issues that may arise when using non-standard or modified components. Hydraulic systems rely on precise engineering and compatibility between various components to function optimally. Non-standard or modified parts may not fit properly or may have different specifications, resulting in leaks, pressure imbalances, or reduced overall performance. Furthermore, the use of non-standard or modified components can impact the overall efficiency and productivity of the concrete pump. OEM parts are specifically designed to work seamlessly with the rest of the system, ensuring smooth operation and maximum output. However, by using non-standard parts, the performance of the pump may be compromised, leading to increased downtime, decreased productivity, and higher maintenance costs. Lastly, the use of non-standard or modified components can also have legal and regulatory implications. Certain jurisdictions may have regulations or standards in place that require the use of OEM or certified parts for specific equipment, including concrete pumps. Failure to comply with these regulations can result in fines, penalties, or legal liabilities in the event of accidents or failures. In conclusion, the potential risks associated with using non-standard or modified hydraulic components in concrete pump spare parts include compromised performance and durability, warranty voidance, compatibility issues, reduced efficiency, and legal and regulatory implications. It is always advisable to use OEM or certified spare parts to ensure the safety, reliability, and optimal performance of the equipment.

- Q: How can a malfunctioning remote control affect the pumping operation?

- The pumping operation can be significantly affected in multiple ways by a malfunctioning remote control. Initially, operators utilize the remote control to operate the pump from a distance, enabling them to control crucial settings such as speed and direction. If the remote control malfunctions, it can hinder operators' ability to effectively control the pump, resulting in delays or inefficiencies in the operation. Furthermore, a malfunctioning remote control can lead to inconsistent or erratic commands being sent to the pump. This instability in commands can cause fluctuation in flow rates, pressure, or other critical parameters, thereby impacting the overall efficiency and effectiveness of the pumping operation. Moreover, there are safety risks associated with a malfunctioning remote control. If the remote control fails to transmit accurate commands, it may cause the pump to operate at undesired speeds or pressures, potentially leading to equipment damage or accidents. Additionally, during emergencies or hazardous situations, the inability to control the pump remotely can hinder operators' prompt response and risk mitigation. Additionally, a malfunctioning remote control can disrupt the monitoring and control systems linked to the pumping operation. Remote controls are often integrated with centralized monitoring systems that provide real-time data and alerts to operators. If the remote control fails, it can interrupt the flow of critical information, making it challenging for operators to monitor the pump's performance, identify issues, or make informed decisions. To conclude, the malfunctioning of a remote control can adversely affect the pumping operation by impeding remote control functionality, causing erratic pump performance, posing safety risks, and hindering monitoring and control systems. Therefore, it is essential to regularly inspect and maintain remote controls to ensure their proper functionality and minimize any potential disruptions to the pumping operation.

- Q: What are the preventive measures for concrete pump?

- In order to ensure the continuity of pumping concrete operation, and ensure the quality of concrete pouring, the interval between the operations should not be too long, so as to prevent clogging.

- Q: Is the main pump of the concrete pump electric control or hydraulic control?

- The main pump behind the oil pump to provide the size of the oil with the greater the current the higher the higher the higher the displacement,

- Q: How often should hopper grate levers be inspected or replaced in a concrete pump?

- Hopper grate levers in a concrete pump should be inspected regularly to ensure proper functioning and prevent potential issues. The frequency of inspections may vary depending on factors such as the intensity of use, the type of material being pumped, and the operating conditions. However, a general recommendation for inspections would be to perform them at least once every six months or after every 500 hours of operation. During the inspection, the hopper grate levers should be carefully examined for signs of wear, damage, or misalignment. If any issues are detected, the levers should be replaced immediately to avoid further damage to the hopper grate system or potential safety hazards. It is important to use high-quality replacement parts that are specifically designed for the concrete pump model in order to ensure optimal performance and longevity. Regular inspections and timely replacements of hopper grate levers will help to maintain the efficiency and reliability of the concrete pump, minimizing downtime and costly repairs.

- Q: Why would the plugging concrete pump pipe

- When pumping, the choice of speed is critical, operators can not blindly map fast, sometimes more haste, less speed. When pumping for the first time, due to the large resistance of the pipeline, the pump should be pumped at low speed. After the pump is normal, the pump speed can be increased properly

- Q: Do concrete pump spare parts come with a warranty?

- Yes, concrete pump spare parts typically come with a warranty. The specific duration and coverage of the warranty may vary depending on the manufacturer and supplier. It is advisable to check the product specifications or consult with the supplier to understand the warranty terms for concrete pump spare parts.

- Q: Can I get spare parts for both piston and rotary concrete pumps?

- Yes, spare parts are available for both piston and rotary concrete pumps.

- Q: What is the importance of a concrete pump control valve?

- A concrete pump control valve plays a critical role in the operation of a concrete pump. It is an essential component that allows for precise and efficient control of the flow and pressure of the concrete being pumped. The importance of a concrete pump control valve can be understood by considering its various functions. Firstly, it regulates the flow of concrete from the hopper to the pumping cylinders. By adjusting the valve, operators can increase or decrease the flow rate to match the specific requirements of the project. This ensures that the right amount of concrete is being pumped, preventing wastage and optimizing productivity. Secondly, the control valve allows for precise control of the pressure in the pumping cylinders. By adjusting the valve, the operator can increase or decrease the pressure to maintain a consistent and steady flow of concrete. This is crucial in preventing blockages or clogs in the concrete pump system, which can lead to downtime and costly repairs. Furthermore, the control valve enables the operator to switch between different pumping modes, such as high-pressure pumping or low-pressure spraying. This versatility allows for the efficient execution of a wide range of concrete pumping tasks, from pouring foundations to spraying concrete for decorative purposes. In addition to its functional importance, a concrete pump control valve also contributes to the safety of the pumping operation. It allows operators to stop or reverse the flow of concrete in case of emergencies or equipment malfunctions. This feature ensures that any potential hazards are quickly addressed, minimizing the risk of accidents and injuries. Overall, the importance of a concrete pump control valve lies in its ability to provide precise control over the flow and pressure of concrete during pumping operations. It ensures efficiency, productivity, versatility, and safety, making it an indispensable component of any concrete pumping system.

- Q: Can concrete pump spare parts be imported from other countries?

- Yes, concrete pump spare parts can be imported from other countries. Many manufacturers and suppliers of concrete pump spare parts have a global presence and offer international shipping options. Importing concrete pump spare parts from other countries can provide access to a wider range of products, competitive pricing, and high-quality components. However, it is important to consider factors such as import regulations, customs duties, and shipping costs when importing concrete pump spare parts from other countries.

Send your message to us

Concrete Lifting Socket for Constrcution Useing

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords