Complete Set of Quenching Equipment (Good Quality)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 6 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application Scope

Quenching heat treatment of metal workpiece.

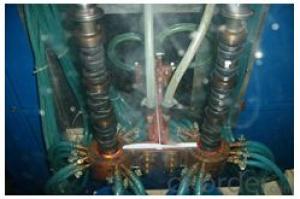

Function Structure

Complete set of quenching equipment is mainly composed of quenching machine tool, quenching power supply (medium frequency power supply, high frequency power supply, super-audio frequency power supply) and cooling equipment. The quenching machine tool is composed of machine tool bed, upper and lower clamping mechanism, clamping and rotating mechanism, cooling system, quenching liquid circulation system and electric control system. Customer can select quenching machine tool as per quenching technics. For special workpiece or technics, the quenching machine tool can be designed and manufactured according to heating technics requirement.

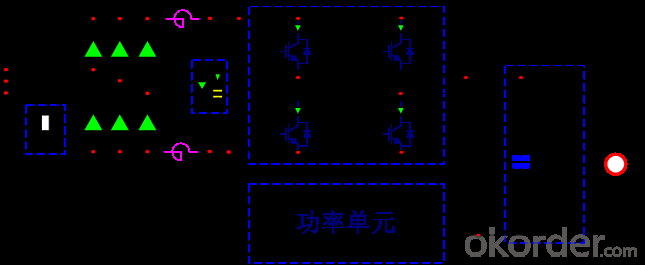

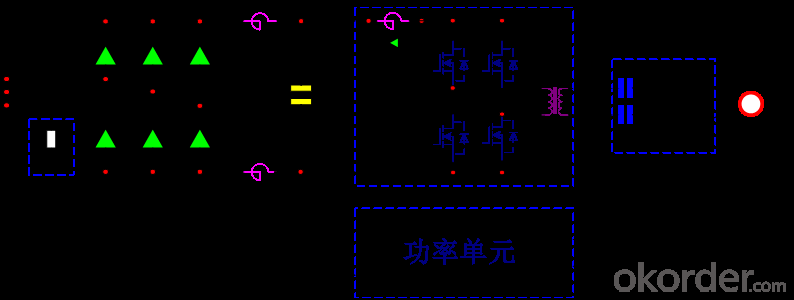

Quenching power supply generally selects parallel induction heating power supply. In order to stabilize quenching frequency to adapt multiple workpiece specifications, tank circuit of quenching power supply need to select quenching transformer.

Technical Features

Ø Perfect structure design

1.Integration design of switchgear rectifying cabinet and inverter output cabinet, with compact structure and small size.

2.The power supply selects DC chopper mode to ensure the grid side power coefficient≥0.92 and a relative lower harmonic content.

3.High standard electromagnetism compatibility design, electromagnetism radiation meets national standard. Closed cabinet design, meeting rigor environmental requirements on site.

4.The shape of quenching inductor is decided by workpiece and quenching technics, and the inductor is well-made.

Ø control system

1. PLC program control or CNC numerical control is optional.

2. AC full digital servo control, numerical control system adopts every advanced control circuits to reduce position tracking error to minimum, and compensate nonlinear error of static/kinetic friction of mechanism system automatically.

3. Quenching machine tool and power supply has perfect protection function with reliable working and low failure rate.

* Can be customized according to user’s requirement.

* equipment selection

Ø penetration heating:A kind of heating method that heat treatment layer is less than current thermal penetration depth, and with suitable specific power density.

Workpiece surface superheat is small, with thin thermal transition layer and high heating efficiency (quenching efficiency is 30~40%)

Ø power:

power density (specific power):The ratio of the power acquired by the workpiece to the heating surface.

| kW/cm2 | simultaneity heating quenching | continuous heating quenching | ||

| Quenching method | specific power scope | commonly used specific power | specific power scope | commonly used specific power |

| M.F. quenching | 0.5~2.0 | 0.8~1.5 | 1.0~4.0 | 2~3.5 |

| H.F. quenching | 0.5~3.5 | 0.8~2.0 | 1.0~4.0 | 2~3.5 |

For workpiece with complicated shape (gear, keyway, eyelet), select lower limit.

For inner hole, flat surface, simple shape compact structure shaft and big workpiece, select upper limit.

Ø power:

For workpiece with complicated shape (gear, keyway, eyelet), the frequency should be lower.

Ø power distribution:

:(simultaneity factor)0.8~0.9

- Q: Should the industrial furnace shell cool down?

- Normally, the furnace shell temperature of an industrial furnace is below 50 degrees, so there is no need to cool down.

- Q: Heat treatment equipment (industrial furnace), which products generally contain what kind of, which industries need to use heat treatment industrial furnace equipment.

- The general metal die casting plant and the metal smelting plant need process melting and dissolving furnace, usually there are reverberatory furnace, cupola, rotary furnace, etc. I do the melting furnace of aluminium alloy.

- Q: What are the companies in the world that are currently engaged in metallurgical furnaces?

- Each manufacturer has its own industry and technological advantages.If you say that the performance rankings, turnover, and so on, it seems that no one has done this ranking.

- Q: What are the combustion equipments used in industrial boilers?

- Main auxiliary equipment for general boilers:1. domestic appliances 2. civilian gas boiler 3. industrial gas furnace.

- Q: What is industrial furnace masonry?

- Masonry industrial furnaces refers to complete materials such as brick kilns in construction process.

- Q: Why does the burner of industrial furnace burn occasionally?

- The flameout protection system is made up of burner controller, electromagnetic valve and flame detector, and the flame detection mode is mainly based on the two forms of ultraviolet detection and electrode detection. By utilizing the electric conductivity of the flame, the circuit path of the combustion process generates a weak current, and when the signal amplifier is amplified, the flame is induced to exist, and the small power burner adopts the detection mode more, and is economical and practical.

- Q: How many kinds of industrial electric furnaces are there?

- Industrial furnace according to the heating mode is divided into two categories: one is the fuel furnace, combustion heat with solid, liquid or gaseous fuel in the furnace for heating the workpiece; the second is in the furnace, the furnace converts electrical energy to heat the heat.

- Q: What are the advantages of a vacuum furnace?

- High degree of integration of mechanical and electrical. On the basis of the improvement of temperature measurement and control accuracy, the workpiece movement, air pressure regulation, power adjustment can be programmed in advance, and quenching and tempering are carried out according to the steps.

- Q: What is the difference between industrial furnace masonry and ordinary masonry?

- Industrial furnace masonry requirements are relatively high, industrial furnaces of different uses, whether material or masonry process, have strict requirements.

- Q: How to use industrial furnace equipment?

- When the furnace is used, the lifting mechanism of the furnace door must be in good condition, and the wire breakage of the steel wire is not allowed to exceed the designated value. The weight should be properly allocated, and the drive department shall be provided with a protective cover.

Send your message to us

Complete Set of Quenching Equipment (Good Quality)

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 6 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords