Complete Pure water Production Line For Bottle Water Project in Cameroon

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Complete Pure water Production Line For Bottle Water Project in Cameroon

Our Whole Pure Water Production Line for PET Bottle Water have been installed and debugged completely in Cameroon.

It is applied for the prodution of pure water, mineral water, beverage product water and process water, high quality, easy operation and maintenance.

The Project is composed of below parts:

1.Pure Water Treatment With RO System 4000L/H,Include the sand filter,carbon filter,resin filter,precision filter,RO system and so on!

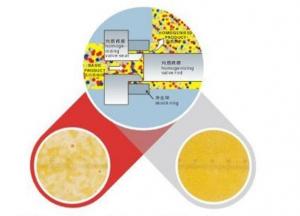

2. "3 in 1"washing,filling,capping machine for bottle water

3. Inkjet Code Machine

4. Automatic Sleeve Shrinking Labels Machine(PVC Shrink Labels)

5. Shrink Stove and Boiler

6. Automatic PE Shrink Packaging Machine

If you interested in our machines,please do not hesitated to contact with us!

- Q: Water treatment conductivity filter how much normal?

- Are you talking about the conductivity of reverse osmosis equipment?

- Q: What is the heat sealing method of hot pressing sealing machine?

- Hot-press sealing machine refers to the way of sealing the packaging container with heat sealing.

- Q: Cleaning and maintenance of what the way

- Cleaning knife knife method: first with the cotton ball will be the next mold of the two drain holes plug, the water into the mold groove, fill up so far, and then pushed into the lower mold slide in place, the pressure on the press

- Q: Filling machine flow and safety regulations

- 1. Before use check: Before starting to ensure that the filling machine power plug connected to the 380V power supply, machine chassis ground wire.

- Q: What is the difference between soft canned sterilization equipment and general equipment?

- if it is flexible packaging canned products, after the sterilization should pay attention to the process of anti-bacterial

- Q: What is the disinfection equipment for water treatment?

- chlorine, are not the desired effect, the use of Danish Danvers DCW imported disinfection equipment, mainly to hypochlorous acid The main compound disinfectant safety,

- Q: Vertical continuous pressure leaf filter

- The process of reducing the consistency of slurry characteristics of the operation.

- Q: The characteristics of the sterilization equipment

- High temperature heat sterilization is mainly through high temperature, the bacteria within the bacteria sterilization, so that the number of bacteria in the food, the total number of bacteria to meet the national food testing standards.

- Q: What are the characteristics of power plant water treatment equipment

- Compared with the latest technology with low cost, easy access to the advantages of supplies.

- Q: The structure of the sealing machine

- Connected to the power supply, the agencies began to work, heating the heating element after heating, so that the upper and lower heating block heated, and through the temperature control system to adjust to the required temperature, press the wheel rotation, according to the need to cool the system began to cool,

Send your message to us

Complete Pure water Production Line For Bottle Water Project in Cameroon

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords