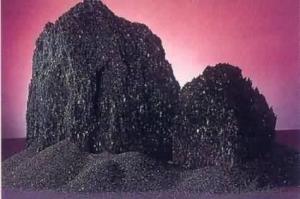

Raw Materials for Refractory:Competitive Price Export Carborundum, Silicon Carbide, Black SiC, Silicon Carbide Alloy Powder

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Place of Origin: | Henan, China (Mainland) | Brand Name: | CBNM | Model Number: | SiC98.5, SiC,98 SiC97, SiC95, SiC90 |

| Application: | Steelmaking & Casting | Shape: | irregular block | Material: | SiC |

| Dimensions: | SiC lump | Chemical Composition: | SiC, Free Carbon, Fe2O3 | color: | black gray |

Packaging & Delivery

| Packaging Details: | 1000 kg plastic woven bag |

| Delivery Detail: | two weeks after making order |

Product Description

Silicon carbide (SiC) is using quartz sand and petroleum coke or coal tar, wood chips (green silicon carbide production need to add salt) such as raw material through high temperature electric resistance furnace smelting.There is also a rare mineral silicon carbide in nature, and the mo SangShi. Silicon carbide is also called the moissanite. In contemporary C, N, B the oxide refractory raw materials in the high technology, such as silicon carbide as the most widely used, one of the most economic, can be called corundum or refractory sand.At present China's industrial production of silicon carbide can be divided into two black silicon carbide and green silicon carbide.

Product grades and chemical composition:

Product grades | Chemical composition(%) | ||

SiC | Free Carbon | Fe2O3 | |

SiC 98.5 | 98.5 min | 0.2 max | 0.6 max |

SiC 98 | 98 min | 0.3max | 0.8 max |

SiC 97 | 97 min | 0.3 max | 1.0 max |

SiC 95 | 97 min | 0.4 max | 1.0 max |

SiC 90 | 97 min | 0.6 max | 1.2 max |

Note: Our company can adjust production according to client’s requirements of other brand of chemical composition and granularity.

Product Effects

Reusable abrasive:

1. Lapping and polishing medium

2. Grinding wheels and grinding medium

3. ear-resistant and refractory products

Blasting systems:

1. Pressure blast systems

2. Injection blast cabinets

Packaging and Delivery

1. Regular products packing with 1000 kg composite woven bags outside for each ton.

2. Special product package with moisture barrier bag.

3. Package with customers' requirement, single packing also can be adjusted according to the size of converter molten pool.

- Q: Who knows what is the external wall thermal insulation materials for level A fireproofing?

- In general, external wall thermal insulation materials can be divided into level A and level B by combustion grading. Level A is non-combustible material, and level B is combustible materials. A few years ago, the fire of the CCTV Building and Shenyang Hotel put the blame on the level B material. At present, the level A material is widely used, and the prices of same level A materials may be even cheaper than the level B material. Level A material is generally divided into thermal?mortar, phenolic foam board, rock wool board and foam cement board. I hope this information can be helpful to you. Hope you adopt.

- Q: What is the difference in the nature between the refractory material and thermal?insulation?material

- thermal?insulation?material is used to thermal insulation and the transfer of heat insulation. refractory material is defined as greater than 1580 ° non-metallic materials, such as calcium silicate board. its using temperature can reach to 1100 degrees, and some can also be used at high temperatures, and all high-temperature industrial can't be oprated without it, and the using temperature of polycrystalline alumina fibers can reach to 1800 degrees

- Q: Who knows the fire rating of fire?partition with steel stud?

- Cement board wall of steel stud: it is used for walls with ceramic in kitchens, restroom, disinfect room, etc. If single-sided tile is made, cement pressure plate can be used on one side. Gypsum board is used on the other side. Fire?rating is A1. CaSo4.2H2O is molecular structural formula of gypsum which contains 20% water, crystal water and free water. When 10% water slowly evaporates on the flame surface, there is still 10% crystal water. Itself is grade A fire retardant material. 1 hour. It is in line with the fireproof test standard of national building materials. It can reach up to 4 hours at most.

- Q: What are the characteristics of magnesium fireproof plate

- Plate glass magnesium fire with high temperatures, flame retardant, sound absorption, shock-proof, pest control, anti-corrosion, non-toxic tasteless non-polluting, can be used directly on the painting, direct veneers, available gas nail directly on the tile, the surface has good coloring , high strength, resistance to bending toughness, nails, saw, can be sticky, easy decoration. It can also be made into thermal insulation materials with a variety of compround composite insulation plate.

- Q: Using what kind of melting aluminium furnace refractories is more appropriate?

- If it's the ordinary, you can use high aluminum refractory brick with general clay, GB/T 3994-2005 clay heat insulation refractory brick. If you need these with good material, there is high alumina thermal insulation refractory brick, GB/T 3995-2006 high aluminum heat insulation refractory brick, models have A13 and material is the alumina, A13 50 u, high insulating brick B5.Intermediate insulating brick B2, etc. Dolomite brick: good hang kiln performance, good erosion resistance, but brick is usually without f - CaO, hydration, and difficult to transport and storage, less used in the production. Magnesia-chrome bricks: good hang kiln, used in calcining zone. The disadvantage is that its thermal shock resistance is poor and plus hexavalent Cr is toxic, the production and use of magnesite chrome bricks in international countries gradually reduce. Now unit using the brick find replacements as soon as possible.

- Q: What are refractory materials?

- Refractories can be divided to two categories based on the shape and three categories according to the chemical nature of acidity, neutralily and alkalinity. Alkaline refractory materials are magnesia-carbon brick, magnesia chrome brick, calcium magnesium brick and magnesia-chrome bricks. Neutural refractory mateial are high alumina brick, corundum brick and clay brick. Case-hardened refractory materials are castable, ramming mass, gunning mix, coated mix, dry vibration material, etc.

- Q: How to choose the material of refractory?

- Long using temperature of aluminum oxide fiber is 1400 ℃, containing chromium aluminum silicate fiber, quartz, high purity aluminum silicate fiber, long-term use of temperature is 1000-1200 ℃ has aluminum silicate refractory fiber according to different raw materials, advanced refractory fiber (such as alumina. Commonly used vitreous aluminum silicate refractory fibre is amorphous, zirconium oxide refractory fibre) using temperature is 1700 ℃ view as >and the best temperature is 1300 ℃. Crystalline refractory fiber are polycrystalline mullite fiber, including ordinary aluminum silicate fiber, alumina and graphite refractory fiber, etc. The use of common refractory fiber temperature is 1150 ℃;>

- Q: What is neutral refractory? Can refractory suppliers tell the main components of it?

- // Baike? Url x3d CQ3i6_yUCWUMgk3aaRGGLURNtvKPl5IdZpj35Yvommk7Nyif0IJD-SkdIW29GCHwLpb9cT9Ii25GLcEJg-ZHcq "target x3d" _blank "x26gt; http://baike.baidu.baidu.

- Q: About the use of horseshoe glass kiln refractories

- the lower portion of advanced clay brick, the lower portion of magnesia-chrome brick arch - high-purity silica brick; flue - clay brick; breast wall--33 # fused zirconia corundum brick (with shrinkage); fused zirconia bottom --33 # fused zirconia corundum brick (with shrinkage); regenerative chamber- the upper part of sintered magnesia-chrome brick, cooling section 33 # electric?smelting no shrinkage fused zirconia corundum brick; the wall - the melting section 41 # no shrinkage fused zirconia corundum brick (including 41% of zirconium; the lattice- superstructure of high purity magnesia brick, the same below); small stove --33 # fused zirconia corundum brick (with shrinkage). It can be said that it is the maximum configuration, if the funds is limited it can be downshift appropriately.

- Q: How to distinguish the fire resistant level of construction materials?

- Building materials fire resistant level is divided into four levels, among which the first level is the highest, with strongest fire resistance; fourth level is the lowest with weakest fire resistance. Fire resistance level of buildings depends on combustion performance and fire endurance of the building components. The building components refer to a series of basic components such as the building walls, foundations, beams, columns, floors, stairs, ceiling, etc.

Send your message to us

Raw Materials for Refractory:Competitive Price Export Carborundum, Silicon Carbide, Black SiC, Silicon Carbide Alloy Powder

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords