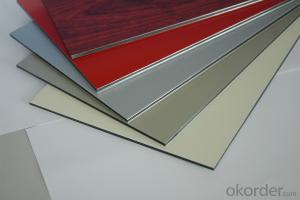

Compact Laminate、Interior decoration, partitions、Compact Laminate Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

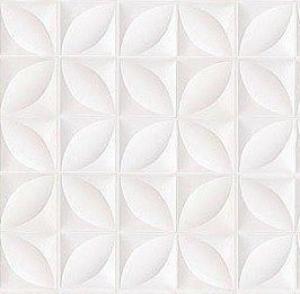

Interior decoration, partitions/Compact Laminate/Compact Laminate Panel

1、Long-term, safe, highly effective antibacterial and mildew-proof.

2、The structure is tight, the strength is high, and the toughness is good.

3、Abrasion-resistant and scratch-resistant surface, impact resistant and durable.

4、Rich in color, strong decoration, solid color, wood grain, stone grain, decor and other finishes.

5、Resistant to high temperatures, the color lasts as long as new.

6、Can be cleaned with warm water, acetone or a mild detergent.

7、Easy to process and install.

- Q: What are the European E1 grade environmental standards?

- When we buy plates or furniture, we often hear such a term: E0, E1 and E2 So what is E0, E1 and E2? Modern furniture and kitchen cabinets are widely used man-made sheet, in order to make the sheet more robust and durable, wood-based panels need to add moisture-proof agent and adhesive, which is the main source of free formaldehyde. E0, E1, E2 are a formaldehyde emission limit level of environmental standards, the first E1, E2 these two standards produced in Germany, by the "EGGER" to develop, after the introduction of European standards, many domestic companies claim that the E0 standard In fact, Europe did not, the highest standards in Europe for the E (1/2). Specific data are as follows: E2 ≤ 5.0mg / L, E1 ≤ 1.5mg / L, E0 ≤ 0.5mg / L. Meet the E0 standard household products, already belong to the international top environmental standards, formaldehyde emission is almost negligible. E0 is produced in Japan, is the most stringent environmental standards, the equivalent of Europe's E (1/2), according to the plate of formaldehyde and other harmful substances to develop the content. China's environmental standards for 10-30mg / 100mg, equivalent to E2 standards. E1 level is "can be untreated, completely harmless to humans and animals." E0 level is the spontaneous standard of some enterprises, rather than mandatory standards. At present the world only Finland, Japan, the two countries to enforce the E0 standard. In China, to strengthen the implementation of the highest standards of the floor is E1, cabinet industry, the national standard only E2, only part of the high-end products are E1. Therefore, if the purchase of Finland, Japan, the origin of the decoration products, that is, E0-class products, basically can be achieved directly to the standard.

- Q: Small size of the bedroom ready to do tatami, the site selection is very troubled, the existing tatami shop, mostly MDF, Daixinban, plywood, finger board, mainly with large amount of plastic, formaldehyde flavor. Some people say that with the Russian red fir, is to buy wood made of sheet and then paint it? Please understand the teacher on the environmental protection, compression capacity to recommend a suitable platform for the plate,

- Hello, do not know where you are tatami, I have done 8 years and the room, I help you solve this problem bars. As we all know: plywood, Daixinban, MDF, etc. are high plastic content of the plate, but here also shows that the formal professional and room manufacturers will not use these plates! In the country, especially in the northern region, with camphor pine in particular, affordable, color texture and feel, by the majority of customers accepted. But here to explain is that even the board is still stitching Pinus sylvestris, the market even if there is a pure use of a full-page, you have to understand, but the choice of large manufacturers of the plate, the general formaldehyde content is controlled Within the scope of the national requirements. Sheet is a sheet, in addition to the column, beams, slide part of the open with a wooden side, and other are generally integrated materials. Speaking of environmental protection, large manufacturers of the plate will generally not use any problems, and then is the paint, paint the quality of the product determines the quality and service life, and the room is generally done varnish processing, is divided into topcoat, primer, And so on multiple processes. Paint paint to be smooth, visual no impurities, feel no bulging particles, film hardness is high. Also give you a recommended plate, that is, Ash. Well, to say so much, the key is to choose the formal professional manufacturers, the current domestic and the room market quite a mixed bag, due to low access threshold, many couples mixed into them, the price war damage is ultimately the interests of consumers. You can go to the formal large-scale building materials store, choose a qualified regular manufacturers! I hope I can help you!

- Q: How to do the corn stalks

- Process Technology Line: 1. Straw density plate: Air dry straw → impurity removal → cut off → wind selection (blown out of the heart) → cans → high pressure steam → spray → fine → spray → drying → pavement → preload → hot pressing → edge → cutting → packaging → finished product 2. Straw crushed plate (particleboard) Drying Straw → Cutting → Wind Selection → Recovering → Drying → Screening → (Surface Layer, Dust, Core Material) → Mixing → Pavement → Preloading → Hot Press → Edge → Cutting → Inspection → Packaging 3. Straw composite board Straw → Cutting → Steam Blasting → Mixing → Paving → Wood Veneer → Glue → Preloading, Hot Press → Side → Varnish → Sanding → Finished 4. New wall materials: Corn stover high grain straw → election → leaves → cut → pavement → irrigation → do the surface layer → veneer → sanding → finished In addition to the above processing, the straw can also be used for pulp making after steam blasting, which is about a third less expensive than traditional pulping methods and only one third of the traditional method. It is helpful to solve the problem of pulp gap caused by the forced cessation of small papermaking by the state. Fourth, the main technical key and expected to achieve the technical and economic indicators: 1. Main technical key: ① developed as low as possible, environmentally friendly, waterproof superior, infiltration of a good name of the glue. ② design and improvement of grading pavement. ③ steam blasting equipment selection and the determination of the main process parameters. ④ hot pressing and cold pressing process parameters adjustment. 2. Expected technical and economic indicators: ① adhesive; solid content: 60% -65% ??????????Free formaldehyde content: 0.2% or less ??????????Viscosity: coated with 4 cups: 30 ℃ 10-20 seconds (fiberboard) ?????????????????????????????????50-65 seconds (particle board)

- Q: 1, if the nose is a metal support, you can hand to the middle of breaking off.

- 1, if the nose is a metal support, you can hand to the middle of breaking off. 2, if the whole into a whole is plastic, nasal care will not be deformed. It must be attached to the lens and the lens between the screws too loose, two mirror feet breaking too open, you can tighten the screw tight. 3. If you have a small wedge, you can tighten the screws on both sides of the frame, it is recommended not to break the glasses to the inside, because the improper grasp of the words easily broken In addition to the optical shop can have a special person will help you tune, of course, is generally selling glasses.

- Q: Know how to help see my description: We told our customers that our PCB is used KB6160 B grade material, and then the customer back to the message said " You are using the KB6160 (FR-4) application of reinforced plate, potentiometer, resistance film field, the lowest level of the kind of plate it! Is very bad.

- I guess the landlord may be a PCB company in the south of it KB sheet, tell the truth, in the industry can be considered the worst. I am in the PCB business to do sales, under normal circumstances, even if the customer requires the use of KB sheet, we will find ways to not let them use, because it is sucks, with the day after the guest complaints continue. I have been to KB in Kunshan factory, feeling like the eighties to bankrupt state-owned enterprises, 5S management mess. The proposed landlord for the plate it, with Kingboard plate, it is hit their own signs.

- Q: Is the cupboard made of tempered glass or oak board?

- Toughened glass is good. Time and then long over the grease are good to wash

- Q: What are the differences between FR5 sheet and FR4 sheet?

- Price FR-5 CCL is much more expensive than FR-4, but the material is really much better. We use FR-5 CCL to produce circuit boards, and UL certification (E301969).

- Q: Is the quality of the letter sheet?

- Did not hear this brand, only know the top ten brands of plates in the bunny, Moganshan, Yu Fu Lin, the Millennium boat, the king coconut, their product quality certainly no problem!

- Q: What are the types of plates for office furniture?

- Particleboard Particleboard is made of wood scrap as the main raw material, and then infiltration of glue, additives made of thin plate. Pressing the press method can be divided into two categories: extruded particleboard, flat particleboard. The main advantage of this type of sheet is the price is extremely cheap. Its shortcomings are also very obvious: very poor intensity. Generally not suitable for the production of large or mechanical requirements of the furniture.

Send your message to us

Compact Laminate、Interior decoration, partitions、Compact Laminate Panel

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords

Productivity Center of Building Materials Industry Co.,Ltd.

Productivity Center of Building Materials Industry Co.,Ltd.