Common Gypsum Board Facing With PVC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

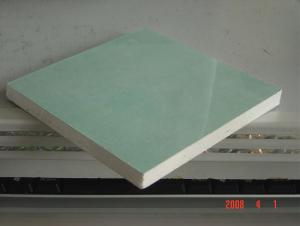

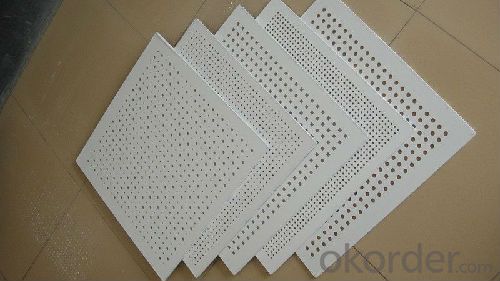

Gypsum board, also known as Drywall/Plaster board, is a panel used typically in interior construction to form a wall or ceiling. The panel has a gypsum core and is faced with heavy paper on both sides, one side specially treated for finishing. Also Known As:Gyp Board, Gypsum Board, Drywall, Sheetrock, Wall Board.

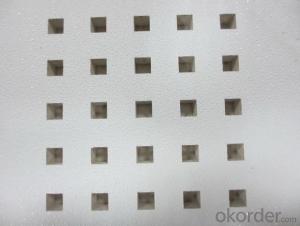

Product Applications:

Mainly used in those places with highg-rade decorationwhere strict acoustic environment is crucial,

such as theater, concert hall, museum, library, hearing room, gallery, auction house, gymnasium,

lecture hall, multifunctional hall, hotel lobby, hospital, shopping mall, piano practice room,

conference room, studio, recording room, KTV room, bar, industrial workshop, machine room, etc

Product Advantages:

1) Environmental, dust and moisture resistant, easy to clean.

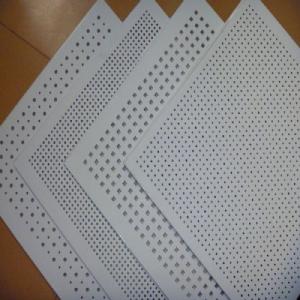

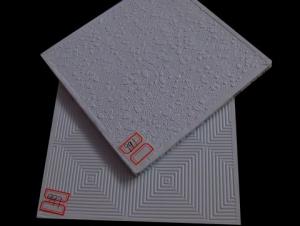

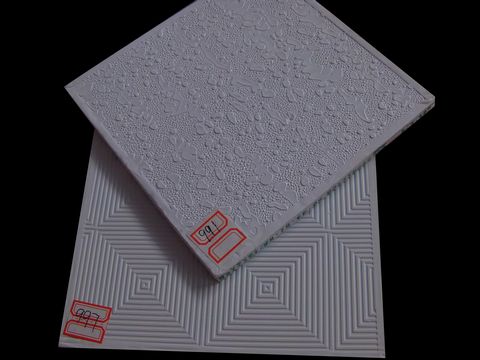

2) Commercial & good for decorative, popular designed patterns for your choosing.

3) Flexible suspension system makes each ceiling tile easily installed and disconnected

4) Easy to match lamps or other ceiling parts.

Main Product Features:

MATERIAL:GYPSUM BOARD

SURFACE:PAPER FACED

EDGE:SQUARE,TARERED

DENSITY:AS PER GB/T9775-1999

BREAKING STRENGTH:AS PER GB/T9775-1999

ANTI-FIRE FUNCTION:<30 MINS AS PER GB8624-1997

COMBUSTION PERFORMANCE:NON-COMBUSTIBLE MATERIAL

SIZE TOLERANCE:LENGTH/WIDTH<+-2.0MM

MOISTURE CONTENT: <2%

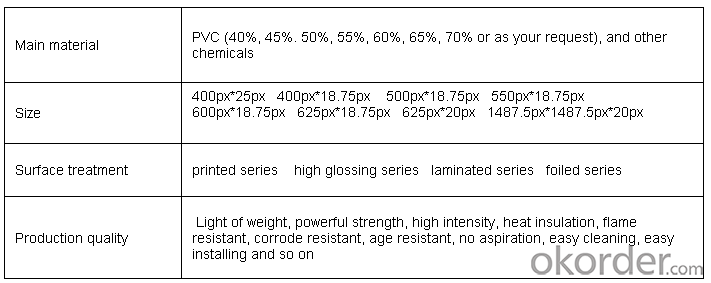

Product Specifications:

FAQ:

•Q: How to calculate product transportation cost?

A: According to the products weight or volume, according to the logistics company quotation.

•Q: Do you provide free sample? And how many days it will take?

A: Yes, we can provide free sample, of course it is better if you would like to pay the courier charge.

•Q: What's our price?

A: We provide resonable quotation.

Images:

- Q: I'm buying a cheap floating shelf for 20 so I can hang it on my bedroom wall (plasterboard). I'm buying it for a new stereo I'm getting , but I don't know how to hang the shelf up. I read somewhere that if you're putting a floating shelf on plasterboard you need to use toggle bolts. Can I just drill the holes in the wall , put wall plugs in , and then screw the shelf in to them. The stereo is a Samsung mini system with two seperate speakers. How can I put it up without a chance of it falling down ?

- Before you commit yourself, check the weight limit of the shelf, if it says anything with its instructions. Floating shelves are not all created equal. Then check the weight of the stereo.

- Q: Three building materials, plasterboard, brick, and wood, all the same thickness and area, are sandwiched to form a wall. Temperatures are 27 degrees Celsius at the inside plasterboard surface and 0 degrees celsius at the outside wood surface. Find the temperature where the plasterboard meets the brick and where the brick meets the wood.k for plasterboard = .40k for brick = .70k for wood = .2

- 1/0.4+1/0.7+1/.2 = 7.5+1/.7 or about 8.93 the plasterboard drops 27*2.5/8.93 C : about 7.7C so temperature at plasterboard/brick is around 19.3 C the wood drops twice as much about 15.2C so brick-wood interface is around 15.2C. Appropriate numerical precision when the conductivities are given to 2 significant figures means your answers should be about 19C and 15C. The brick is awful! Have a look at the link below; even thermal grease isn't much worse than this brick but the values do seem to be pretty typical.

- Q: hello I intend on insulating and plaster boarding my shed soon. However I am not entirely sure of the best way to plasterboard onto a metal frame, because I do not want screws poking out of the board because you cannot nail into metal obviously. So I was wondering do most people use only liquid nails or how else is the board applied to the frame? I heard you can put small pieces of wood between the frame and the board then nail to the wood, is this a good technique? advice and opinions would be much appreciated thanks

- use bolts. plaster and paint over to hide them. get the rounded, covered nuts to go on the outside of the shed.

- Q: how much does a a sheet of soundbloc plasterboard cost?

- ?8.11 including VAT for a 2400 x 1200: 12.5cm At Joseph Parr in Middlesbrough

- Q: ive bought metal anchor bolts to fix semi pesistal basin to wall(4) but im not sure if its strong enough to hold it.i also cant work out how to connect same diameter waste pipe(cummin out of wall) to chrome waste trap?please help.

- When a bathroom or powder room is first built they usually mount a solid frame at the correct height and position in the wall for mounting a hanging/pedestal type sink. This allows proper bo;lts to be screwed into a solid base so the sink does not fall off later. You require a P-trap available in hardware stores and building supplies. The P-trap should have the proper fittings to connect to both the drain pipe and the Tail pieces in your sink.

- Q: Ask the wall, that top of the ceiling with gypsum board, the above can be directly painted it? Still have to do putty ah?

- Gypsum board ceiling, in fact, and the wall to do gypsum board partition is basically the same. Gypsum board to do a good job, the wall of the processing process can be carried out in accordance with the following steps. 1, seam processing. Gypsum board and gypsum board is stitching together, or large or small must have a seam. This kind of joint, if handled properly, in a very short period of time may be cracking. At present, no one can do so that these seams at 100% never crack. However, there is an international common practice is to delay the cracks at the crack, of course, can not do 100% never crack, but it is recognized and effective. With our tourmaline repair gypsum, for example, the operation process is as follows: "with a good mix of the goods will fill the slats and fill, and along the slit wipe a layer of gypsum to paste fiber reinforced mesh cloth (self- Cloth paste directly after the paste), compaction grid cloth and then wipe a layer of the product, the thickness of not more than 2mm board, until it is dry (about 2 hours), and then the whole wiping a product leveling. Mesh cloth can be replaced with kraft paper bandage. 2, scraping putty. It is best to put the first putty, do not omit this step. Gypsum board, are generally paper gypsum board, the outermost layer is paper, which is the most vulnerable place of gypsum board. Where the paper is generally a problem, the future will certainly be cracking from here and other issues. Latex paint moisture content is very high, gypsum board of paper is so much water infiltration once, it is no guarantee that no problem, if there is putty layer to do what buffer is much better. In addition, after the joint treatment, scraping putty can make the grassroots level, more uniform. If you do not scratch the putty, do the place where the gap and the color of the paper may have a certain color.and then paint.

- Q: Do you use a gypsum board to make a wall that is neither strong nor clean?

- The plate can be considered with the Erit board skeleton with the root of the root to do an anti-Hom

- Q: Well we are moving outta the house so few jobs to do. Im not sure what to do with these....

- You could get some spackle and a putty knife and try to fill and sand it that way.. or some joint compound and a trowel (watch some youtube videos on how) and sand it and paint it.

- Q: We have a wall in between a bedroom & the landing that bows when you press it.We pulled some paper off to see what was underneath & plaster crumbled away, theres now 2 big holes in the wall & it seems only the paper is holding it together.You can see the wood slats under the plaster but they are very weak. We are desperate to get this sorted so we can put our house on the market . We've been told to just bang plasterboard on top of it all, we were going to crumble all of the old plaster off & then apply plasterboard.Can anyone suggest what would be best? Thanks

- it seem the wall is lathe and plaster ...if you look at the plaster carefully you will see hairs sticking out from it ...this is horse hair ..it was put in to give a better grip as the hairs curled around the gaps in the lathe ...you have two choices ..either remove loose plaster ...pva exposed lathes ..then apply BONDING COAT plaster ..and then skim ..or remove all plaster ..and board over ..the upright studs will be spaced at 16centres ..scrim the joints and plaster with BOARD FINISH

- Q: Public equipment, we are the first brush latex paint, and then brush fire paint, the results cracked, there has been a large drop of the situation. Gypsum board and MDF are the emergence of this situation, seeking God guidance

- Gypsum board above do not need to brush fire paint, if you must brush, then brush fire latex paint, a direct solution to the problem.

Send your message to us

Common Gypsum Board Facing With PVC

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords