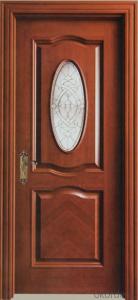

Coloured Wooden Door Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Piece/Pieces pc

- Supply Capability:

- 5-10 x 20'' FCL/month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

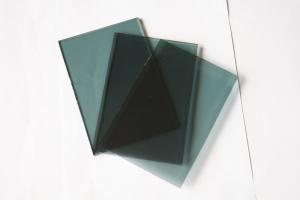

Function: Acid Etched Glass,Decorative Glass,Heat Absorbing Glass,Heat Reflective Glass,Insulated Glass,Low-E Glass

Shape: Flat

Structure: Solid

Technique: Clear Glass,Figured Glass,Frosted Glass,Laminated Glass,Stained Glass,Tempered Glass,Tinted Glass

Type: wooden door glass

Certificate: ISO9001

Specification: 22'X64'

Thickness: 1inch for wooden door glass

Size: 22'X64',07'X64' for wooden door glass

Packaging & Delivery of Coloured Wooden Door Glass

Packaging Details: strong wood crates

Delivery Detail: Based on the qty

Specifications of Coloured Wooden Door Glass

1. 13 years manufacturing experience for wooden door glass

2. ISO9001,IGCC/IGMA,SGCC

3. Best Quality and Price

Specification for Wooden Door Glass:

Material: strong tempered glass, patterned glass, sheet glass

Color: clear or colored are all available.

Specification/Size: 914.4*558.8, 1219.2*558.8, 1625.6*558.8, 1219.2*203.2, 457.2*177.8, 1135*205 etc. We can cut the glass into your required size.

Thickness: 17 mm to 25.4 mm.

Technology: clear tempered glass, acid etched glass, mistlite backing, panel glass with bevels and clusters, colored glass, patterned glass for decorative

Application: kitchen, entry doors, interior doors, windows, veranda, cathedral etc.

Features for Wooden Door Glass:

There are triple panel glass to constitute, both of the surface are smooth with the vivid design in the middle panel.

Unique design for modern style, strong material to prevent bump, keep warm, hot resistance, lively color to attract eyes

Decorative glass just belong to you: We can make the design just as you like.

High-quality glass that guarantee our glass are fabricated strictly and checked carefully on each process, they can be used for many ways.

- Q: What kind of raw material is glass made of?

- Composition of common glass chemical oxides (Na2O, CaO, 6SiO2)Glass is usually divided into oxide, glass, and non oxide glass by major components. Non oxide glass varieties and a small number, mainly sulfur glass and halide glass. Chalcogenide glass anion for sulfur, selenium and tellurium, can stop short wave light by yellow, red, and near infrared light, which has low resistance, switching and memory characteristics. Having low refractive index, low dispersion, and often used as optical glass.

- Q: What are the anticorrosive materials for glass fiber reinforced plastic?

- FRP is made of glass fiber and epoxy resin, is the best anti-corrosion material, regardless of category, can be anti-corrosion.FRP corrosion protection is generally stipulated in the GB50212-2002 building corrosion control project construction and acceptance specifications and CD130A19-85 hand paste FRP design technical specifications.

- Q: Yacht enterprises are purchasing their own raw materials (resin, glass fiber, carbon fiber, etc.), home composite products, accessories?

- I do PVC mesh fabric, and it should be used on the hull of your yacht

- Q: What kind of glass is smoked glass?

- * clarifierIn the process of making glass, some bubbles will appear. Reducing the bubbles is the use of fining agents, mainly arsenic trioxide, antimony oxide and nitrating salt

- Q: Medium temperature glass flake clay products

- Glass scales prevent the erosion of base material by water vapor and chemical solvents. The degree of chemical resistance of the substrate or coating varies with the chosen glass material, and the glass scale, which is made of c- glass, has excellent chemical durability.

- Q: What's the difference between three kinds of glass fiber board, epoxy board and FR4 board?

- FR4 is the pure epoxy board of NEMA standard. The normal color should be dark green. This is the color of epoxy. There are also yellow, generally called yellow FR4 called yellow material, white (green) called white material.FR4 is more expensive than epoxy board and fiberglass board cannot confirm the price.

- Q: The shell of glass steel electric cars will not be on the poor out of the glass Sizha?

- Such as glass fiber reinforced plastic products used for a long time will cause bare glass fiber, this situation is only a very low-end manufacturers will appear, because they use the resin does not know where it came from. Really sophisticated material manufacturers out of the glass steel shell, even if your car is worn out, will not appear bare glass phenomenon, unless you use a weapon to draw it. I worry about the effects of glass fiber dust on the body, that you do not have to worry about, FRP is inferior can lead to itching, and the glass tube can do high-quality drinking water, the quality of glass steel products has been cured is harmless to the human body.

- Q: There are several ways of heating the industrial drying tunnel furnace and are different from each other?

- The utility model has the advantages of long service life and high reliability. The heater is made of special electric heating material, and the design power load is reasonable, and the heater adopts multiple protection, so that the safety and the service life of the heater are greatly increased.

- Q: Is glass fiber reinforced metal material?

- Glass steel (English: Glass Reinforced Plastic, GRP, or Fiber Reinforced Plastic, English: FRP) also known as glass steel or glass fiber reinforced plastic, is a kind of polymer with epoxy resin as matrix, glass steel or carbon fiber reinforced composite material by composite technology and made.

- Q: What's the difference between crystal and ordinary glass?

- To strike lightly or with fingers. Crystal glass can produce metal crisp sound, and waves a beautiful lingering in the air. We will see at the reception banquet, high-end glasses scenes in the movie, a kind of glass between the collision sound is. And high school, low grade crystal glass sound is also different. Like some low-end crystal glass or ordinary glass voice is relatively boring.

1. Manufacturer Overview

| Location | Jiangsu,China (Mainland |

| Year Established | 2002 |

| Annual Output Value | |

| Main Markets | North America Southeast Asia Oceania |

| Company Certifications | ISO9001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | SHANGHAI |

| Export Percentage | |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English, Chinese |

| b) Factory Information | |

| Factory Size: | Below 1,000 square meters |

| No. of Production Lines | 1 |

| Contract Manufacturing | OEM Service Offered |

| Product Price Range | |

Send your message to us

Coloured Wooden Door Glass

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 Piece/Pieces pc

- Supply Capability:

- 5-10 x 20'' FCL/month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords