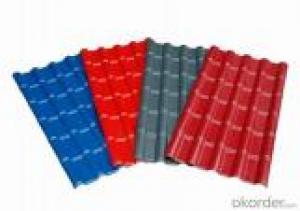

FRP Corrugated Lighting Sheet in Different Colors

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

Specifications of Good Quality FRP Corrugated Lighting Sheet

FRP Sheet made by serial machinery of FRP sheet have the advantages of smooth surface, even thickness, high impact strength, good weather resistance as well as high productivity. It is the best materials for the surface panels of top grade refrigeration vehicles for its excellent properties of heat and moisture insulaiton.

Thickness:0.8mm、1.0mm、1.2mm、1.5mm、2.0mm、2.5mm、3.0mm;

Width:1000mm、1200mm;

Color:Clear/Lake Blue/Sky Blue/Light Green/ Opal;

Length:30m/rolling

Applications of Good Quality FRP Corrugated Lighting Sheet

They are applied to steel structure workshops, warehouses, weather sheds, car parks, weather corridors, lighting sheds, sun sheds,

greenhouses, etc. They are the ideal materials for the choices of enterprises and institutions.

The necessary characters of high quality FRP Corrugated Lighting Sheet:

1. small air bibbles

2. no bubbles

3. anti-aging resin

4. high property upper film(or gelatum)

5. high quality non-alkali fiber-glass

6. consistent high light transmission

7. high chemistry corrosion resistance

8. high anti-ultraviolet property

9. even thickness

Package& Delivery of Good Quality FRP Corrugated Lighting Sheet

Wooden pallet,according to custom requires.

Technological Parameters of Good Quality FRP Corrugated Lighting Sheet

Density 1.5 g/cm3 Tensile strength 100Mpa

Fiber content >25% Bending strength 160Mpa

Curing degree >82% Impact ductility 135 KJ/㎡

Gel Coat Thickness 20-150μm Thermal conductivity 0.158 W/m.k

Weathering film thickness 20-30μm Thermal expansivity 2.2X10-5mm/mm/℃

Light transmissivity 60-85% Water absorption 0.32%/24hr

Suitable temperature -40℃-120℃ UV Rate 99.9%

Thickness:0.8mm、1.0mm、1.2mm、1.5mm、2.0mm、2.5mm;

Color:clear, sky blue,lake blue & opal;

Length:cut as per customers' requirements on the condition that it is suitable for transportation

Pofiles:over 10 profiles for you choice at present:For detailed profiles please visit:820-205, 840-210, 760-380, 950-237,930-79, 812-203, 406-203 and so on

- Q: Synthetic resin tile tile for flat slope, in the election when the tile, how to choose?

- Synthetic resin tile tile for flat slope, in the election of the tile, pay attention to the following slightly, to ensure that you choose a good tile

- Q: My house building to do the top floor is covered with resin tiles below the wood is fixed, did not do the water on the cover directly to the rainy day to rain, especially under the heavy rain on the leakage of the larger rain along the wall Down the drain, because we are in the countryside are in the local Please do the self-taught artisans do now do not know how the matter is so hard for the rest of my life to do the house now can not live to ask which expert to help our home out of ideas Analyze it

- There are problems, you can see my name to search, give you answer Synthetic resin tile installation method: purlins can choose square tube steel (60 * 40 * 3mm) or C steel (100 * 50 * 20 * 3mm) or wood (60 * 40mm), need to do anti-corrosion treatment according to the resin tile type to determine the spacing of purlin (bamboo tile spacing of 750mm), arranged from the bottom up the main tile installed according to the local wind direction reverse installation, two tiles between the horizontal overlap of a crest (including the ridge tile lap) size of 80mm, vertical lap a tile pitch, lap in the purlins contact parts Must be fixed with self-tapping bolts in the case of two slope roof, to be two symmetrical slope of the installation of the slope, in order to facilitate the installation of the corrugated tile is consistent the slope of the torsion tile in the end of the installation of the end of the installation of the torsion bar, is into the ridge tile and the corrugated tile should be dealt with the formation of flattened, so as to be into the three-way ridge tile installation the installation of the ridge when the tile is to avoid the main tile with the seam coincidence to reduce the installation gap fixed for the special self-tapping bolt, the first pad of good bolts and then use the electric wrench moderate tightening, and then cover the water to take

- Q: What are the synthetic resin tiles for the roof? What is the benefit of using synthetic resin tiles

- Reinforced concrete roof synthetic resin tile installed before the roof structure layer, waterproof layer, insulation layer, leveling layer has been completed and through the acceptance

- Q: Synthetic resin tile for flat to slope, do not wild, mobile housing, garden loft where the advantages?

- Synthetic resin tile for flat to slope, do not wild, mobile housing, garden loft advantage lies in the following: 1

- Q: I would like to ask you, in addition to ASA synthetic resin tile, what is the tile ah?

- I would like to know that the ASY synthetic ASA synthetic tile tile only, stable non-fading long, acid and alkali corrosion, light weight, high strength.

- Q: The difference between the synthetic tile tile roof and the ridge tile and their installation method

- Synthetic resin tile from the height of the ridge, for the different regions are not used, because to prevent the snow after the roof load is too large, the south from the ridge height is small, the north is large

- Q: Is it also used for heat preservation with synthetic resin tiles?

- color retention: in the National Chemical Building Materials Testing Center hours of artificial aging test, synthetic resin tile color change (ΔE) is equal to 223 impact: in the free fall hammer test, 1 kg heavy steel hammer From 15 m height free fall on LCNEST watts, no cracks low temperature resistance: In the freeze-thaw cycle test, after 10 freeze-thaw cycle, synthetic resin tile surface without hollowing, blistering, peeling and cracks and other issues anti-load: in the National Chemical Building Materials Testing Center test, support interval 660mm, increased 150 kg, no cracks damaged heat insulation: synthetic resin tile thermal conductivity of 01Kcal / mh ° C, is steel 1/ concrete 1/12 Fire safety by the National Chemical Testing Center to reach B1 level water resistance: synthetic resin tile surface "SABIC" resin dense non-absorbent, there is no problem of microporous water seepage Installation of a single fast single, extra high efficiency, easy to lift, complete supporting products, the process is simple

- Q: Synthetic resin tile used in what place more, in addition to flat slope change it ~

- The use of high-tech chemical technology developed from the new building materials, generally applicable to the development zone Ping-slope, farmers market, shopping malls, residential quarters, new rural construction residents high-end villas, awnings, awnings, antique buildings

- Q: Why is the price of synthetic resin tile 3.0 cheaper than 2.0?

- High-quality synthetic resin tile weight range High-quality synthetic resin tile density of about 1

- Q: 150 square meters of housing roof pouring glazed tiles how much money

- Glazed tile is a small piece of a small piece of stitching, lap 1 square meters about 33 glazed tiles, glazed tiles of the market price of 2-2

Send your message to us

FRP Corrugated Lighting Sheet in Different Colors

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords