Aluminum Coil Pipe for Outer Wall Color Prepainting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

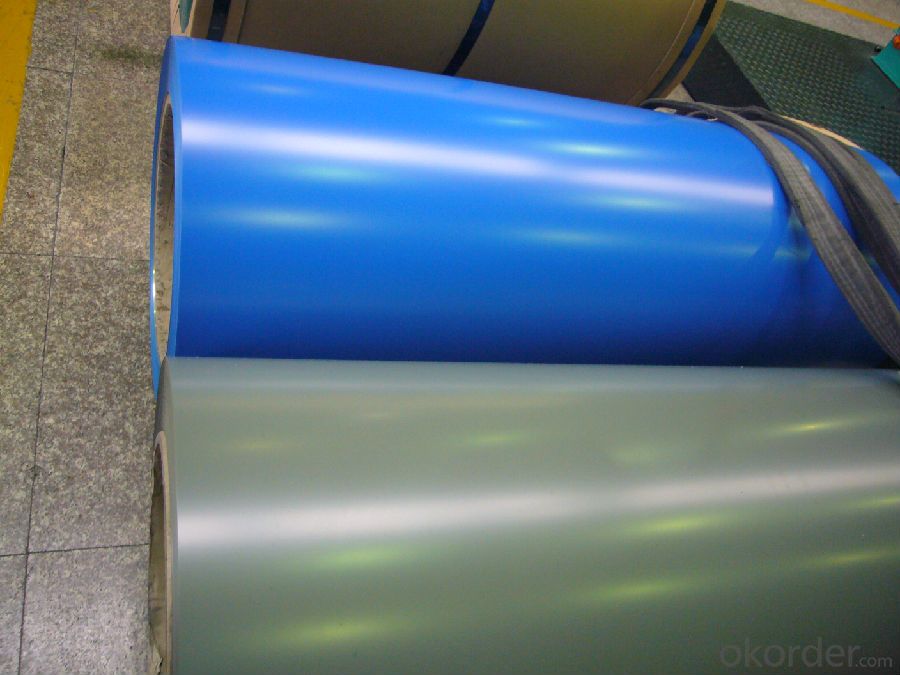

1.Structure of Color Prepainting Aluminium Coils for Outer Wall

Color Prepainting Aluminium Coils for Outer Wall is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Color Prepainting Aluminium Coils for Outer Wall

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| ALLOY | Temper | Coating Thickness | Coating | Weight |

| AA1050 | H14 | 20-25 MICRONS | PE | 2 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: Can aluminum coils be used in automotive body panels?

- Yes, aluminum coils can be used in automotive body panels. Aluminum is a lightweight and corrosion-resistant material, making it an ideal choice for automotive applications. The use of aluminum coils in body panels offers several advantages, including improved fuel efficiency due to the reduced weight of the vehicle, better handling and maneuverability, and enhanced durability. Additionally, aluminum is highly recyclable, making it an environmentally friendly option for automotive manufacturing. Many automakers have already started incorporating aluminum coils in their vehicles, and this trend is expected to continue as the industry strives for lighter and more sustainable vehicles.

- Q: Can aluminum coils be welded or joined together?

- Yes, aluminum coils can be welded or joined together using various methods such as TIG (Tungsten Inert Gas) welding, MIG (Metal Inert Gas) welding, or using specialized aluminum welding techniques.

- Q: Can aluminum coils be utilized to create jewelry boxes and other decorative objects?

- <p>Yes, aluminum coils can be used to make jewelry boxes and other decorative items. Aluminum is lightweight, durable, and has a shiny finish that can add a touch of elegance to decorative pieces. It can be easily shaped and manipulated using various tools and techniques, such as bending, cutting, and engraving. Additionally, aluminum's resistance to corrosion makes it a practical choice for long-lasting decorative items. However, it's important to consider that working with aluminum may require specific skills and tools, and the final appearance can be influenced by the quality of the aluminum and the craftsmanship involved.</p>

- Q: How are aluminum coils coated to enhance their durability?

- Aluminum coils are coated through a process called coil coating, where a thin layer of protective material is applied to enhance their durability. This coating can be done through various methods such as roll coating, spray coating, or coil coating lines. The coating material used is typically a combination of resins, polymers, and additives, which provide resistance against corrosion, UV rays, abrasion, and other environmental factors. This coating process helps to extend the lifespan of aluminum coils and maintain their appearance and performance even in harsh conditions.

- Q: Can aluminum coils be used in solar thermal systems?

- Yes, aluminum coils can be used in solar thermal systems. Aluminum is a commonly used material for heat transfer in such systems due to its excellent thermal conductivity and corrosion resistance.

- Q: How much is one square aluminum gate and five hard door?

- Double layer aluminum alloy, in the middle of the 5 bars, ordinary white or beige is 215, a square, the motor, in addition, the general 600KG copper core motor has 550 sets, there are 680 sets. On the Alibaba website search "roll gate", there are many manufacturers, you can ask them.

- Q: Is it possible to utilize aluminum coils in creating art pieces or decorative items?

- <p>Yes, aluminum coils can be used to make artworks or decorations. Aluminum's malleability and durability make it an excellent material for crafting. It can be bent, twisted, and shaped into various forms, allowing for creative expression in art and design. Additionally, aluminum's resistance to corrosion and weathering makes it suitable for both indoor and outdoor decorative pieces. Artists often appreciate its lightweight nature and the metallic finish that can be polished or painted, offering versatility in artistic applications.</p>

- Q: Hi,I am fairly new to design and have been doing technical drawing for only a few months. We have an item, that supports up to about 800KG of weight, as a C shaped channel. We are currently making this out of 3mm Mild Steel. Due to a new design, we are changing this design to avoid welding and painting the above part. This means we will be making the part from Galv sheet.I would like to make the part from Aluminium because 1) There will be no rust, 2) I think it will look better than Galv sheet but I need to keep the cost down.We use 3mm mild at the moment, because it is easier to weld than 2mm, not for strength really.Therefore, my question is, in everybody's opinion, would it be OK to make it from 2mm Aluminium, or is this likly to end in disaster?FYI, the part is 1600mm long, then on each long side there are presses of up 250mm, down 80mm and down 20mm. The weight is supported at 4 points on the 80mm flanges.What a question for my first go Answers! TIA

- Aluminium is expensive as far as I know. I would do the costing on the aluminium first. Also aluminium is a little weaker so you'll need a thicker sheet. I would go with galvanised.

- Q: who discovered aluminum and in what year did they discover it?

- Aluminum was named for one its most important compounds, alum. Alum is a compound of potassium, aluminum, sulfur, and oxygen. The chemical name is potassium aluminum sulfate, KAl(SO4)2. No one is sure when alum was first used by humans. The ancient Greeks and Romans were familiar with the compound alum. It was mined in early Greece where it was sold to the Turks. The Turks used the compound to make a beautiful dye known as Turkey red. Records indicate that the Romans were using alum as early as the first century B.C. It was first ISOLATED in 1827 by German chemist Friedrich W?hler (1800-82). W?hler used a method perfected by English chemist Sir Humphrey Davy (1778-1829),

- Q: How do aluminum coils compare to other metal coils in terms of cost?

- Compared to other metal coils, aluminum coils are typically more cost-effective. This is mainly because of the plentiful availability of aluminum as a raw material and the relatively inexpensive extraction and production processes. Furthermore, aluminum coils provide a lightweight and long-lasting solution, thus reducing costs associated with transportation and installation. Moreover, aluminum is resistant to corrosion, which eliminates the necessity for frequent maintenance and replacement expenses. On the contrary, alternative metal coils like copper or stainless steel may have higher initial costs and necessitate additional coatings or treatments to prevent corrosion. Consequently, when evaluating the overall cost, aluminum coils are often a more economical option.

Send your message to us

Aluminum Coil Pipe for Outer Wall Color Prepainting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords