color coated steel plate 1000 Ton/Tons per Week

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | SGCC, DX51D+Z, S320GD+Z, S280GD+Z, S350GD+Z | Thickness: | 3-120 |

| Place of Origin: | Shanghai China (Mainland) | Brand Name: | baosteel | Model Number: | SGCC, DX51D+Z, S320GD+Z, S280GD+Z, S350GD+Z |

| Type: | Steel Plate | Technique: | Hot Rolled | Surface Treatment: | Coated |

| Application: | widely used for roofs, outer walls, cabinets | Width: | 914/1000/1200/1219/1220/1250mm | Length: | 3000mm-6000mm |

Packaging & Delivery

| Packaging Detail: | Mill's standard export packing |

| Delivery Detail: | 20-35 days after get the deposit |

Specifications

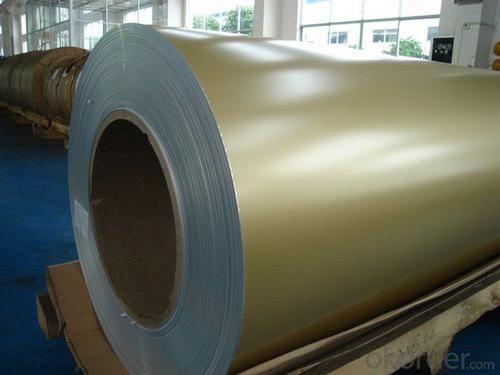

color coated steel plate

Standard:ASTM AISI BS GB JIS DIN

Thickness:3.0-120mm

Material: SGCC, DX51D+Z, S320GD+Z, S280GD+Z

1) Product Name: hot dipped Galvanized Steel sheet in coil DX51D

2) Quality Standard & Grade: JIS G3302/ ASTM 653M / EN10142 DX51D

3) Thickness: 0.18mm-1.2mm

4) Width: 762mm/800mm/900mm/914mm / 1000mm / 1200mm / 1219mm / 1220mm / 1250mm

5) Thikness tolerance: +/-0.02mm

6) Width tolerance:+/0.02mm

7) Zinc coating weight: 60g/m2-180g/m2 , Z60-Z180

8) Surface of Product: regular spangle / big spangle/ zero spangle

9) Surface Treatment: chromated , non oiled, skin passed

10) Packing: Mill's standard export packing

11) Country of Origin :China

12)Applications:widely used for roofs, outer walls, cabinets

13)Delivery Time :30 days

14)Shipment: By bulk vessel or By container

- Q: Can steel sheets be used for interior wall applications?

- Yes, steel sheets can be used for interior wall applications. Steel sheets provide durability, strength, and fire resistance, making them suitable for various interior wall applications such as in commercial buildings, industrial spaces, and residential homes. They can be installed as wall panels, partitions, or cladding, offering a modern and sleek aesthetic. Additionally, steel sheets can be easily customized, painted, or coated to match different interior design preferences.

- Q: Are steel sheets resistant to staining?

- Yes, steel sheets are resistant to staining.

- Q: What are the different shapes available for steel sheets?

- Steel sheets come in a variety of shapes to meet specific requirements and applications. Some commonly used shapes include: 1. Basic and versatile, flat sheets have a flat surface and come in different sizes and thicknesses. They are widely used in construction, automotive, and manufacturing industries. 2. Coils are continuous lengths of sheet metal wound into a roll. They are ideal for large-scale production processes in industries like appliances, automobiles, and HVAC systems. 3. Perforated sheets have evenly spaced holes throughout. They are used for ventilation, filtration, or aesthetic purposes in architectural designs, signage, and industrial machinery. 4. Corrugated sheets have parallel ridges and grooves that offer strength and rigidity. They are commonly used for roofs and siding due to their durability and weather resistance. 5. Expanded metal sheets are created by cutting and stretching a flat sheet, resulting in diamond-shaped openings. They are used for ventilation, security, or filtration purposes in fences, walkways, and machine guards. 6. Diamond plate sheets, also known as tread or checker plates, have raised diamonds or lines on their surface. They are popular for flooring, stairs, ramps, and truck bed liners because they provide traction and slip resistance. These examples represent just a few of the available shapes for steel sheets. The choice of shape depends on project requirements, including strength, durability, aesthetics, and functionality.

- Q: Can steel sheets be welded or joined together?

- Yes, steel sheets can be welded or joined together. Welding is a common method used to join steel sheets together. It involves melting the edges of the sheets and then allowing them to cool and solidify, creating a strong bond between the two sheets. Welding is an effective way to join steel sheets as it provides a durable and permanent connection that can withstand high levels of stress and load. Additionally, other methods such as riveting, bolting, and adhesive bonding can also be used to join steel sheets together depending on the specific application and requirements.

- Q: Are steel sheets easy to weld?

- Yes, steel sheets are generally easy to weld due to their high heat conductivity and good weldability.

- Q: Are steel sheets suitable for data center infrastructure?

- Yes, steel sheets are suitable for data center infrastructure. Steel is a strong and durable material that can provide the necessary structural integrity and support for data center equipment and systems. It is commonly used for server racks, cabinets, enclosures, and other components within data centers. Steel sheets offer stability, protection, and easy customization options, making them a reliable choice for data center infrastructure.

- Q: What is the typical coefficient of thermal expansion of a steel sheet?

- Steel sheets typically have a coefficient of thermal expansion of approximately 10-12 ppm/°C. This signifies that for every degree Celsius rise in temperature, the steel sheet will expand uniformly in all directions by 10-12 ppm. However, it is crucial to acknowledge that the coefficient of thermal expansion may differ based on the precise type and composition of the steel. Various steel alloys may exhibit slightly varied coefficients, although the range of 10-12 ppm/°C is widely accepted as the average.

- Q: Can steel sheets be bent without causing damage?

- Provided that the bending process is carried out with caution and within the material's limits, steel sheets can be bent without sustaining any damage. Various techniques, such as press brake bending or roll bending, are commonly employed to bend steel sheets. These methods involve applying controlled force and pressure to achieve the desired shape without causing any lasting deformations. Several factors influence the ability to bend steel sheets without harm. These factors include the thickness and grade of the steel, the bending radius, and the equipment and technique employed. Thinner sheets are generally more pliable and easier to bend, while thicker sheets may necessitate greater forces and specialized equipment. To ensure that the bending process does not exceed the steel's limits, it is crucial to consider its tensile strength, yield strength, and elongation properties. Over-bending can result in cracks, fractures, or permanent deformations that compromise the sheet's structural integrity. To prevent damage during the bending process, it is vital to follow proper bending techniques and guidelines. This includes using suitable tooling, distributing force evenly, and avoiding abrupt changes in direction or excessive bending angles. Additionally, preheating the steel sheet can enhance its pliability and reduce the risk of damage. In conclusion, steel sheets can be bent without damage, but it necessitates careful consideration of the material's properties, appropriate equipment, and adherence to bending guidelines. By employing the correct techniques and precautions, steel sheets can be successfully bent into various shapes and forms while preserving their structural integrity.

- Q: Are steel sheets resistant to radiation?

- No, steel sheets are not inherently resistant to radiation.

- Q: Can steel sheets be used for fire-rated doors?

- Yes, steel sheets can be used for fire-rated doors. In fact, steel is one of the most commonly used materials for fire-rated doors due to its high strength, durability, and fire-resistance properties. Steel sheets used in fire-rated doors are typically constructed with multiple layers of fire-resistant material, such as gypsum or mineral core, sandwiched between the steel sheets. This construction helps to prevent the spread of fire and smoke, providing a reliable barrier in the event of a fire. Additionally, steel is known for its structural integrity, making it a suitable choice for fire-rated doors that need to withstand high temperatures and pressure.

Send your message to us

color coated steel plate 1000 Ton/Tons per Week

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords