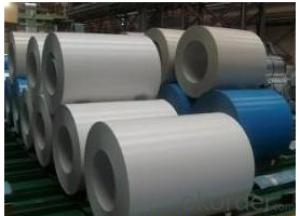

Color Coated Steel Coils/ Pre-painted Steel Coils/ Sheets /PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Galvanized steel coil features:

. Zinc coating :40-275g( as required)

. thickness:0.17-1.2mm

. width:914-1250mm(900mm,1215mm,1250mm,1000mm the most common)

. Coil id:508m610mm

. Coil weight: 3-12(as required)

. Surface treatment: cremated, oiled, skin passed

. Spangle: regular,small, zero

2. Application of Galvanized steel coil features

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

3.Painting colour steel , zinc coated steel , lead coated steel

Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | DX51D,SGCC,SPCC,CGCC | Thickness: | 0.17-1.2mm |

Place of Origin: | Taian China (Mainland) | Brand Name: | HengJi | Model Number: | HJ |

Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | RAL color cremated, oiled, skin passed |

Application: |

building metal roofing components,house appliance | Width: | 914-1250mm | Length: | customized |

price: | favorable price | Our Customers | Steel force, Stemcor, Duferco, Samsung , G&G,Hyosung,CNBM |

4.Painting colour steel image:

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your Warranty?

Warranty: 1-Year for the whole light. Warranty is based on correct storage, installation, using and maintenanc

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible.

- Q: I'm writing a book, and there is a part where there is a death arena with a white-hot river of steel. How hot would that be?

- I had the Odyssey white steel # 5 and absolutly hated it. I gave it away. I didn't like the feel on lag putts. I now putt with a Scotty Cameron Circa 62 #2 and I love it. Would highly recommend a Scotty Cameron for anyone.

- Q: So finally got around to watching man of steelnow i heard a few times that batman was in iti didn't se him.in the film is it something subtle I've just missed or is he not in it?when i googled it got loads of results for them being together in the new film but nothing about man of steel 2013

- Zod okorder /

- Q: What are steel coils used for?

- Steel coils are used for a variety of applications, including manufacturing automobiles, construction materials, appliances, and machinery. They are also used in the production of pipes, electrical appliances, and packaging materials.

- Q: What are the different types of steel coil surface treatment options?

- There are several different types of steel coil surface treatment options available, each serving a specific purpose and providing various benefits. Some of the common surface treatment options include: 1. Hot-dip galvanizing: This process involves immersing the steel coil in a bath of molten zinc, which forms a protective zinc coating on the surface. Galvanizing provides excellent corrosion resistance and helps in extending the lifespan of the steel coil. 2. Electro-galvanizing: Similar to hot-dip galvanizing, but instead of immersing the coil in molten zinc, an electric current is used to deposit a thin layer of zinc onto the steel surface. Electro-galvanizing provides a smoother and thinner zinc coating, making it suitable for applications that require a more aesthetic finish. 3. Pre-painted or coated: Steel coils can be coated with a layer of paint or other protective coatings before they are formed into various products. This type of treatment provides additional protection against corrosion and enhances the aesthetic appearance of the steel coil. 4. Organic coating: Organic coatings are typically applied to steel coils to provide protection against corrosion and improve the overall durability of the product. These coatings can be in the form of epoxy, polyurethane, or other types of polymer-based materials. 5. Pickling: Pickling is a surface treatment process that involves removing impurities and scale from the steel coil by immersing it in an acid solution. This treatment helps in improving the adhesion of subsequent coatings and prepares the surface for further processing or finishing. 6. Oil coating: Steel coils can be coated with a thin layer of oil to protect the surface from oxidation and rust during storage or transportation. This coating is typically used as a temporary measure and is usually removed before further processing. 7. Shot blasting: Shot blasting involves propelling small metal particles at high velocity onto the steel coil surface. This process helps in removing rust, scale, and other contaminants, providing a clean and roughened surface for better adhesion of subsequent coatings. These are some of the commonly used steel coil surface treatment options. The choice of treatment depends on the specific requirements of the application, such as corrosion resistance, aesthetic appearance, or improved adhesion.

- Q: What are the dimensions of steel coils used in automotive component manufacturing?

- The dimensions of steel coils used in automotive component manufacturing vary depending on the specific application and requirements. However, common dimensions include thicknesses ranging from 0.5mm to 3mm and widths ranging from 600mm to 2000mm.

- Q: every time i look for steel over the internet like to build cars motorcycles ect i only get steel pipes where can i get steel sheets

- This okorder /... Most towns have a steel supply house/ business, check your yellow pages. Also check with local welding and machine shops. They can give you ideas and or their suppliers. They often have bits and pieces that you might buy, instead of ordering a full sheet of material. Wingman

- Q: so my parents gave me stainless steel cookware for christmas and the first time i used it i cooked chicken. it stuck to the pan and where the oil splattered it cooked on and turned it dark black and brownish. and the bottom too. i don't cook with it because i don't want to burn it on anymore but i don't know how to clean it. how do i cook without burning anything, aside from a lower flame and how on earth do i get the stains on. i've tried almost everything too! thanks.

- Dear pwrgrlmanda, I also use stainless steel. I have found the best way to clean any cookware that has food baked or cooked on it is by filling my sink with the hottest water possible, submerging the entire piece of cookware in the sink and then liberally sprinkling cascade powder over the top. Allow it to set overnight and usually in the morning everything will come off with a nylon scrubber. It really works! No more elbow grease. This also works for corning ware, glass baking pans, cookie sheets etc. Hope it works for you.

- Q: How are steel coils used in the production of steel plates?

- The production of steel plates heavily relies on steel coils, which play a crucial role. These coils serve as the primary raw material and are vital in the manufacturing process. The initial step involves creating steel coils by heating and cooling molten steel to form thin, flat strips. These strips are then further processed in a rolling mill, where they undergo a series of rollers to decrease their thickness and increase their length. Once the desired dimensions are achieved, the steel coils are uncoiled and straightened. This involves passing them through a machine to eliminate any curvature or deformities, ensuring that the strips are completely flat. Subsequently, the straightened coils are cut into specific lengths to match the required dimensions of the steel plates. After being cut, the coils undergo another significant step called leveling. This step involves passing the strips through a leveling machine to remove any residual stress or warping that may have occurred during the production process. Leveling guarantees that the steel plates possess a consistent thickness and are free from any distortions, making them suitable for various applications. When the leveling process is completed, the steel coils are finally transformed into steel plates. These plates can be further processed according to the desired end-use. They may undergo additional treatments like heat treatment, surface finishing, or coating to enhance their strength, durability, and resistance to corrosion. To summarize, steel coils serve as the starting point in the production of steel plates. They undergo several essential steps, including rolling, uncoiling, straightening, cutting, and leveling, to convert them into flat and uniform steel plates. These plates can then be further processed and tailored for a wide range of applications in industries such as construction, automotive, shipbuilding, and manufacturing.

- Q: Cold rolled steel coil steel, what is the difference?

- From the last finishing mill stand out of the hot strip laminar cooling through to the set temperature, the coiling machine rolled strip steel roll cooled, according to the different needs of users with different finishing line (flat, straightening, transverse or longitudinal, inspection, weighing, packing and marking etc.) processing and become steel, flat steel product volume and slitting, its strength is not very high, but the ductility and weldability is good, the appearance of color is not bright, easy to corrosion, because the price is cheap, the majority of enterprises in order to reduce the cost, so the more commonly used.

- Q: What are the different methods of skin pass rolling for steel coils?

- Steel coils can undergo skin pass rolling using various methods, each possessing its own distinctive characteristics and advantages. Some commonly employed techniques include: 1. Dry Skin Pass: This method entails passing the steel coil through rolls without applying any lubricant or coolant. The absence of these substances aids in enhancing the steel's surface finish by minimizing thickness fluctuations and achieving a smoother texture. 2. Wet Skin Pass: This approach involves utilizing a water-based emulsion or coolant during the skin pass rolling procedure. The coolant serves to decrease friction and heat generated during rolling, resulting in improved surface quality and reduced risk of surface defects. 3. Electrolytic Skin Pass: This technique utilizes an electrolytic solution during skin pass rolling. The steel coil is submerged in the solution, and an electric current is applied to the coil, leading to controlled surface etching. This method is particularly effective in improving surface cleanliness and eliminating oxide scale. 4. Temper Mill Skin Pass: This method combines skin pass rolling with a tempering process. The steel coil undergoes a series of rolls, followed by a heating and cooling process to achieve the desired mechanical properties and surface finish. This method is commonly employed for high-strength and automotive-grade steel coils. 5. Tension Leveling: In this method, the steel coil is passed through a series of rolls while under high tension. This elongates the steel, reducing residual stresses and shape defects, thereby enhancing flatness and dimensional stability. It is important to note that the selection of a skin pass rolling method depends on factors such as the desired surface finish, required mechanical properties, and the type of steel being processed. Each method offers its own advantages and limitations, and manufacturers typically choose the most suitable approach based on their specific needs.

Send your message to us

Color Coated Steel Coils/ Pre-painted Steel Coils/ Sheets /PPGI

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords