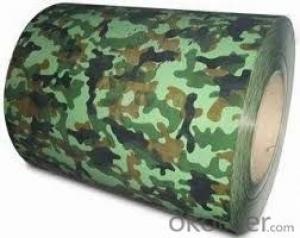

Color Coated Hot Rolled Steel Coil/PPGI Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | ASTM,GB,JIS | Grade: | STEEL | Thickness: | 0.18MM-0.8MM |

| Place of Origin: | Zhejiang China (Mainland) | Brand Name: | sukalp | Model Number: | 820 |

| Type: | Steel Coil | Technique: | Cold Rolled | Surface Treatment: | Coated |

| Application: | HOUSE AND BUILDING | Special Use: | High-strength Steel Plate | Width: | 500MM-1600MM |

| Length: | as your request | Zinc coating: | 40-275g/m2 | Coil ID: | 508mm/610mm |

Packaging & Delivery

| Packaging Detail: | export package |

| Delivery Detail: | 15 days after receipt the deposit |

Specifications

Pre-Painted Steel Coil

1)Thinkness of pre-painted steel coil 0.18MM-0.8MM

2)Width of pre-painted steel coil 500MM-1600MM

Pre-Painted Steel coil Features Specifications:

Galvanized steel is hot or cold-rolled strip steel belt of substrates, through continuous hot-dip galvanizin process.It is good in corrosion resistance,high in surface quality, convenient in deep-processing,low cost. Widely used in silo,the fish up , the chimney, kitchen utensil, handicraft, construction formwork, household electrical appliance, roller shutter door, garage door, wave wattand colored substrate,etc.

Product details:

Product | Hot dip galvanized corrugated steel coil/sheet |

material | SGCC,SGCH,SGCE,SPCG,DX51D,Q195,Q235 |

Thickness | 0.13-0.6mm |

Width | 914-1500mm(according to your need) |

Zinc coating | 40-275g/m2 |

Spangle | Regular, small, big or zero |

Coil Weight | 3-8tons |

Capacity | 250,000 tons/year |

Coil ID | 508mm/610mm |

- Q: Can you use regular welding rods when welding stainless steel?Thank you.

- You would use stainless steel rod. I have used stainless safety wire that you can buy at the hardware store or Harbor Freight. (Assuming you are TIG welding). I have found that for small jobs it works quite well.

- Q: I am using mild steel wire (very thin and bendable) for an art project, and would like to know if using a soldering torch is effective enough to get the job done. Or do I have to use a butane torch to heat the metal?BTW, is it better to use soft or hard solder?

- Soldering Steel

- Q: what is magnetic steel used for and if it can be used for producing kitchenwares utenils like stainless steel basines,mugs and bowls.

- Magnetic steel rusts. That's why kitchenware is often made out of stainless. You can't turn magnetic steel into stainless, sorry. Metalurgy is a complicated subject, and is all about different alloys. It's far too involved to explain in a few paragraphs here, but no, they're not interchangeable in this case unless you want to produce kitchenware that rusts.

- Q: Can steel coils be coated with holographic patterns?

- Yes, steel coils can be coated with holographic patterns. The holographic coating can be applied to the surface of the steel coils, creating a visually stunning and unique effect.

- Q: What are the typical coil thickness options?

- The typical coil thickness options vary depending on the specific application and industry. However, common coil thickness options range from 0.005 inches (0.13 mm) to 0.250 inches (6.35 mm).

- Q: it seems like the hardness of Stainless steel, i saw 410c stainless stell, i saw 440c stainless steel, what does it means anyway?

- 440c Stainless

- Q: How are steel coils inspected for edge quality?

- Steel coils are inspected for edge quality through a combination of visual inspection and non-destructive testing methods. Visual inspection involves a thorough examination of the edges of the coils to identify any visible defects such as cracks, chips, or uneven edges. This is typically done by trained inspectors who carefully inspect the entire length of the coil. Non-destructive testing methods are also used to detect any hidden defects or imperfections in the edges of the steel coils. These methods include ultrasonic testing and magnetic particle inspection. Ultrasonic testing involves the use of high-frequency sound waves to identify any internal flaws or discontinuities in the steel. Magnetic particle inspection, on the other hand, uses magnetic fields and particles to identify any surface or near-surface defects in the steel. Both visual inspection and non-destructive testing methods play a crucial role in ensuring the edge quality of steel coils. By conducting these inspections, manufacturers can identify and address any defects or imperfections in the edges of the coils, ensuring that they meet the required quality standards.

- Q: Would the Ruger Sr22 pistol or the SW MP 15-22 be any good for the steel challenge?

- Steel plates are very difficult for a .22lr

- Q: and what type of metal is steel?

- Iron and carbon is call mild steel, low carbon steel or high carbon steel depending on the percentage of carbon use , higher the carbon is used the tougher the steel is .but as far as I vaguely remember, in high carbon steel its only 3% of less carbon. Iron in its pure state is called wrought iron which is soft. Then there are Tool steel, High speed steel [drill bits and cutting tools are made]. Spring steel. [springs ] are made. Then we have alloy steel is another

- Q: What are the different methods of edge trimming for steel coils?

- There are several methods of edge trimming for steel coils, depending on the specific requirements and application. Some of the common methods include: 1. Slitting: This is one of the most common methods used to trim the edges of steel coils. It involves passing the coil through a set of circular knives that cut the edges into narrower strips. Slitting can be done in-line during the manufacturing process or as a separate operation. 2. Shearing: Shearing is another popular method used for edge trimming. It involves using a set of blades to cut the edges of the coil in a straight line. Shearing is often used when precise and clean cuts are required, and it can be done manually or with the help of automated machinery. 3. Laser cutting: Laser cutting is a more advanced method that uses a high-powered laser to trim the edges of steel coils. This method provides precise and smooth cuts, and it is often used when high accuracy and quality are essential. Laser cutting can be incorporated into the production line or performed as a standalone process. 4. Grinding: Grinding is a method that involves using abrasive wheels or belts to remove material from the edges of steel coils. It is commonly used to remove burrs, rough edges, or surface imperfections. Grinding can be done manually or with the help of automated machines, depending on the scale and complexity of the trimming process. 5. Waterjet cutting: Waterjet cutting is a method that utilizes a high-pressure jet of water mixed with abrasive particles to trim the edges of steel coils. This method is known for its versatility and ability to cut through a wide range of materials and thicknesses. Waterjet cutting is typically used when complex shapes or intricate designs need to be achieved. Overall, the choice of edge trimming method for steel coils depends on factors such as the desired accuracy, speed, complexity of the edges, and the specific requirements of the application. Different methods offer varying levels of precision, efficiency, and cost-effectiveness, allowing manufacturers to select the most suitable technique for their specific needs.

Send your message to us

Color Coated Hot Rolled Steel Coil/PPGI Coil

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords