Adp Aluminum Coil Cx360b635 - Color Coated Aluminum Coil CNBM Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l Product Introduction

Color Coated Aluminum Coil is widely used in manufacturing aluminum thin sheet and aluminum foil. It is suitable for further machining with original standard quality. It is easy to be controlled and be manufactured to according to requirements.

l Product Specification:

Name | Color Coated Aluminum Coil | |

Brand | CMAX | |

Alloy | 1100,1235,3003,3004,3005,3105,5005,5052,8011 | |

Thickness | 0.2mm~200mm | |

Width | 40mm -1500mm | |

MOQ | 5T | |

Coating finish | PVDF,POLYESTER,NANO,BRUSHED | |

Color | As to code RAL | |

Surface | Embossed,Mill Finish,Coated | |

Gloss | 10-90%(EN ISO-2813:1994) | |

Total coating thick | PVDF 25 micron | |

Polyester 18micron(EN ISO-2360:1995) | ||

Coating hardness | 2H | |

Adhesion | 5B (EN ISO-2409:1994) | |

Impact resistance | No cracking and peeling (A.S.T.M D2794-1993) | |

Flexibility (T-bend) | 0T- 2T | |

MEK resistance | 100 | |

Certification | ISO9001,SGS | |

Usuage | Exterior applications | wall cladding, facades, roofs and canopies, tunnels, |

Interior applications | wall cladding, ceilings, bathrooms, kitchens and | |

Advertisement and market applications | display platforms, signboards,fascias and shop fronts | |

Coil's standard diameter | 1100mm | |

Coil's standard weight | 2000kgs | |

Botton side aluminium sheet is coated with protective polyester material,thickness more than 6 micron | ||

l Packaging & Delivery

Packaging detail: Standard seaworthy exporting carton, Wooden pallets, waterproof paper and plastic coverage or as customer's requirements

Delivery detail: about 25 days from received oiginal L/C or advance payment

l Company Profile

CNBM International Corporation, China National Building Materials (Group) Corporation, is one of the largest companies in China building material & equipment industry, with 42,800 employees and sales in 2005 of US Dollar 4.395 billion. In 2006, China National Building Material Company Limited was listed on Hong Kong Stock Market with the stock code as 3323.

The business scope of CNBM covers from manufacturing and sales of a series of building materials to scientific research and design, import and export trade. In many of these fields, CNBM is playing the leading role.

l CNBM World Wide

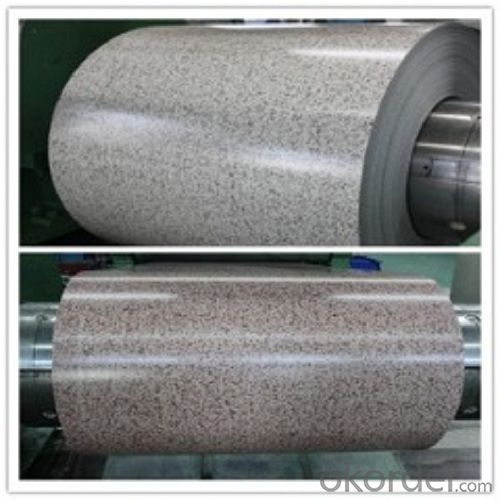

l Product Images

l Certificates

l FAQ

Q: Do you provide free samples?

A: Yes, free samples will be sent to you on freight at destination.

Q: Can I get your latest products catalogue?

A: Yes, it will be sent to you in no time.

Q: What is the MOQ?

A: 5 tons

Q: What are your payment terms?

A: We accept L/C, T/T.

l Contact Us

Email: service@okorder.com

- Q: Are there any limitations on the coil flatness of aluminum coils?

- Yes, there are limitations on the coil flatness of aluminum coils. Aluminum coils, like any other metal coils, are subject to certain tolerances and limitations in terms of flatness. Flatness refers to the deviation of the coil surface from being perfectly flat. The American Society for Testing and Materials (ASTM) has established standards for measuring and evaluating the flatness of metal coils, including aluminum coils. These standards provide guidelines for manufacturers, suppliers, and customers to determine the acceptable level of flatness for a given application. The acceptable flatness of aluminum coils can vary depending on factors such as the thickness of the coil, the grade of aluminum used, and the intended use of the coil. Thinner coils generally have stricter flatness requirements compared to thicker ones, as they are more prone to distortion and waviness. Coil manufacturers employ various techniques to control and improve flatness, such as tension leveling, roller leveling, or corrective leveling. These processes help to reduce or eliminate any deviations in flatness that may occur during the coil manufacturing or processing stages. It is important to note that achieving perfect flatness in aluminum coils is not always possible due to the inherent properties of the metal. Aluminum has a tendency to exhibit some degree of natural springback, which can result in slight variations in flatness. However, these variations are typically within acceptable tolerances for most applications. Ultimately, the limitations on the coil flatness of aluminum coils depend on the specific requirements of the customer or industry. It is essential for manufacturers and suppliers to communicate and establish clear flatness specifications to ensure that the coils meet the desired quality standards.

- Q: How are aluminum coils used in the production of furniture and fixtures?

- Aluminum coils are commonly used in the production of furniture and fixtures due to their lightweight and durable nature. They are mainly utilized for manufacturing furniture frames, legs, and other structural components. Additionally, these coils can be easily shaped and formed into various designs, allowing for versatility in furniture design. The use of aluminum coils also ensures resistance to corrosion, making the furniture suitable for indoor and outdoor settings.

- Q: How are aluminum coils used in the production of signage and displays?

- Aluminum coils are widely used in the production of signage and displays due to their versatility, durability, and cost-effectiveness. These coils are typically made from high-quality aluminum alloy, which provides excellent strength and resistance to corrosion. In the production process, aluminum coils are first unwound and then passed through a series of rollers to achieve the desired thickness and shape. This process, known as coil coating or pre-painting, allows for the application of various finishes and coatings onto the surface of the aluminum. These coatings can include polyester, polyurethane, fluorocarbon, or acrylic, depending on the specific requirements of the signage or display. Once the aluminum coils are coated, they can be further processed into different forms, such as flat sheets, strips, or even customized shapes based on the design requirements. The versatility of aluminum allows for easy fabrication and customization, making it a popular choice for signage and display manufacturers. Aluminum coils are commonly used in a wide range of signage applications, including billboards, outdoor advertising panels, trade show displays, store signage, and architectural signage. The lightweight nature of aluminum makes it easy to transport and install, reducing production and installation costs. Moreover, aluminum's durability ensures that signage and displays made from aluminum coils can withstand harsh weather conditions, UV radiation, and other environmental factors, making them suitable for both indoor and outdoor applications. The corrosion-resistant properties of aluminum also contribute to the longevity of the signage, ensuring that it maintains its appearance and functionality over time. In addition to its physical properties, aluminum's aesthetic appeal is another reason for its extensive use in signage and displays. The smooth and reflective surface of the metal provides an attractive finish that enhances the visual impact of the signage, helping to grab attention and communicate messages effectively. Overall, aluminum coils play a crucial role in the production of signage and displays by offering versatility, durability, cost-effectiveness, and aesthetic appeal. Their ability to be easily customized, combined with their resistance to corrosion and harsh environmental conditions, makes aluminum an ideal material for creating eye-catching and long-lasting signage and display solutions.

- Q: What are the color options available for aluminum coils?

- The color options available for aluminum coils are vast and varied. Aluminum coils can be coated with a wide range of colors through a process called coil coating. This process involves applying a layer of paint or coating to the aluminum surface to enhance its appearance and provide additional protection against corrosion and weathering. Some common color options for aluminum coils include white, black, gray, silver, bronze, and metallic finishes. Additionally, custom colors can also be created to match specific design preferences or brand requirements. These custom colors can be achieved through a color matching process where the desired color is formulated and then applied to the aluminum coils. It is worth noting that the availability of color options may vary depending on the manufacturer and supplier. However, with the advancement in coil coating technology, the range of color choices for aluminum coils has significantly expanded, allowing for greater flexibility in design and aesthetics.

- Q: Can aluminum coils be used in water treatment plants?

- Yes, aluminum coils can be used in water treatment plants. Aluminum is a commonly used material in various water treatment processes, such as filtration, sedimentation, and coagulation. It is known for its corrosion resistance and durability, making it suitable for handling water and various chemicals commonly used in treatment plants.

- Q: This question asks about potential safety hazards when using electric heaters that have aluminum coils.

- <p>While electric heaters with aluminum coils are generally safe when used properly, there are some safety concerns to consider. Aluminum can heat up quickly and may become very hot, posing a risk of burns if touched. Additionally, aluminum coils can corrode over time, potentially leading to electrical shorts or fires. It's important to ensure that the heater is not covered or obstructed, as this can cause overheating. Always follow the manufacturer's instructions for use and safety precautions. Regularly inspect the heater for any signs of damage or wear, and never use a heater with a damaged cord or plug.</p>

- Q: What is the balanced chemical equation for aluminum and cobalt?That is all the information that the question gives. If you could help me out, I would really, really appreciate it.

- That's pretty sparse. Perhaps the question is referring to a single replacement reaction. Aluminum is above cobalt in the activity series, which allows us to predict that aluminum metal will reduce cobalt ions, while aluminum is oxidized. This occurs as long as there is an ion present which will react with the aluminum oxide layer on the surface of aluminum. This passivating Al2O3 layer keeps aluminum metal from reacting. The presence of chloride ions will break down the passivating layer allowing the aluminum metal below to react. Al2O3(s) + 6H+ + 8Cl- -- 2[AlCl4]- + 3H2O(l) 2Al(s) + 3Co2+ -- 2Al3+ + 3Co(s)

- Q: Can aluminum coils be used for solar panel installations?

- Yes, aluminum coils can be used for solar panel installations. Aluminum is a commonly used material in the solar industry due to its lightweight, durability, and corrosion resistance. Aluminum coils can be used as framing materials for mounting solar panels, providing a sturdy and long-lasting support structure. They also offer excellent heat dissipation properties, which is important for efficient solar panel performance. Additionally, aluminum coils are easy to work with, making the installation process more convenient. Overall, using aluminum coils for solar panel installations is a popular and effective choice.

- Q: What are the potential safety hazards when using a soldering iron on copper or aluminum coils?

- <p>Using a soldering iron to solder copper or aluminum coils can pose safety risks. Copper and aluminum can react when joined, potentially leading to a galvanic corrosion. Additionally, the high heat from the soldering iron can cause the metal to expand or deform, especially if not handled properly. Always ensure proper ventilation to avoid inhaling fumes from the soldering process. Wear heat-resistant gloves and safety glasses to protect against burns and flying debris. Ensure the work area is clear of flammable materials to prevent fire hazards.</p>

- Q: Are there any limitations or drawbacks of using aluminum coils?

- Yes, there are some limitations and drawbacks of using aluminum coils. One limitation is that aluminum coils tend to be more expensive than other coil materials, such as copper. This can make them less cost-effective for some applications, especially when large quantities of coils are required. Another drawback is that aluminum coils have a lower thermal conductivity compared to copper coils. This means that they may not transfer heat as efficiently, which can impact the overall performance of the system. In applications where heat transfer is critical, copper coils may be preferred. Aluminum is also more prone to corrosion compared to other metals. Although aluminum coils are typically coated or treated to enhance their resistance to corrosion, they can still be susceptible to damage in harsh environments or if the coating is compromised. This can lead to reduced efficiency and a shorter lifespan for the coils. Furthermore, aluminum coils may not be suitable for certain applications that require high strength or durability. Aluminum is a relatively soft metal, so it may not be able to withstand heavy loads or extreme conditions as effectively as other materials. Lastly, aluminum coils can be more challenging to repair or replace compared to other coil types. Due to their unique properties, specialized tools and techniques may be required for maintenance or repairs, which can add to the overall cost and complexity. Overall, while aluminum coils have their advantages, it is important to consider these limitations and drawbacks when selecting the appropriate coil material for a specific application.

Send your message to us

Adp Aluminum Coil Cx360b635 - Color Coated Aluminum Coil CNBM Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords