Aluminum Sheets Hawaii - Color Coated Aluminium Coils Polyester Coating AA3004

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

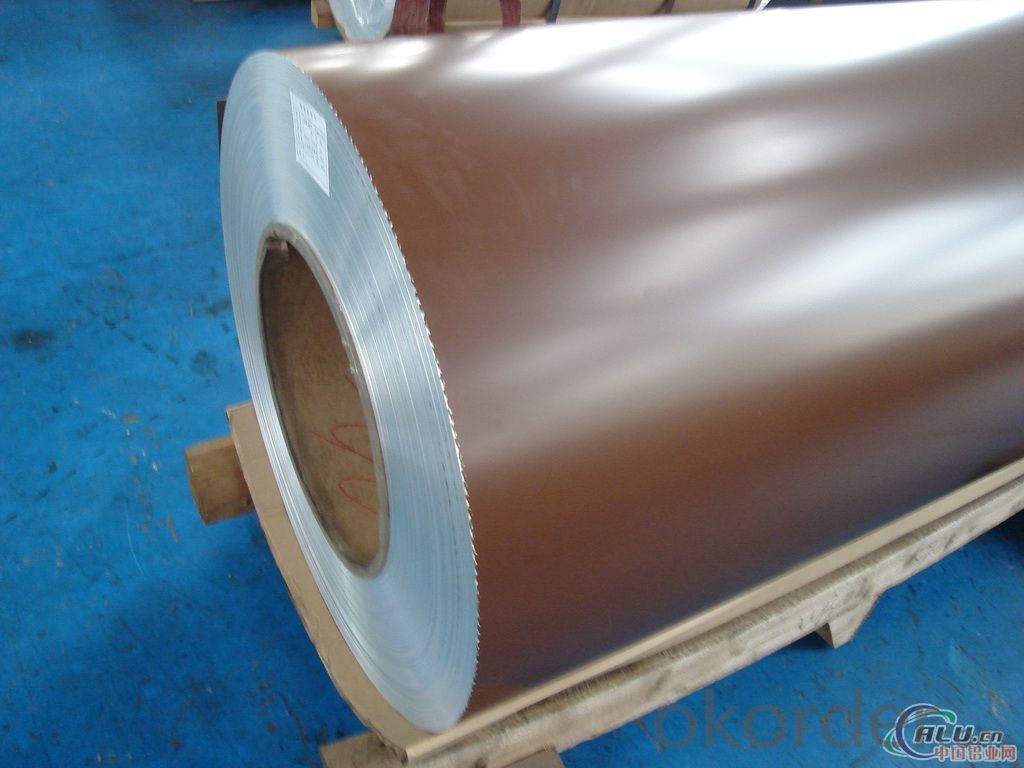

1.Structure of Color Coated Aluminium Coils

PE Coated aluminium coils are widly used in decoration field. For the painting, it depends on the using evironment. If you use in the open air, we recommend the PVDF coated aluminium coils. This kind of painting can last 15-20 years. If you use in the room, we recommend PE coated aluminium coils. The price is much more competitive.

2. Main features of Color Coated Aluminium Coils

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| ALLOY | Temper | Thickness | Width | Weight |

| AA3003 | H14 | 0.2mm-3mm | 1200MM-1800MM | Min 5 tons |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: If one were to hit someone with a baseball bat, would it cause more pain to use a wooden bat or an aluminum one? Just wondering.

- I've been chased with an aluminum bat, but haven't ever been hit with either. I would say that the wooden bat would hurt more, because that's solid wood. An aluminum bat is hollow. But then yet, I've red articles where aluminum bats perform better for some kind of scientific reason that I didn't quite understand. So if an aluminum bat performs better on a baseball, it would be safe to assume that perhaps it would hurt more to be hit with an aluminum one. But either way, it's safe to say... I'd rather not be hit with either!

- Q: What specific conditions or criteria need to be met when installing aluminum windows to ensure they are properly fitted and functional?

- <p>When installing aluminum windows, there are several special requirements to consider: ensuring the frames are level and square, using the correct size and type of fasteners, applying a proper sealant to prevent air and water infiltration, and adhering to local building codes. Additionally, it's crucial to check for thermal insulation properties, especially in areas with extreme weather conditions. The installation should also allow for proper drainage to prevent water damage. Professional installation is often recommended to meet these requirements and ensure the windows function correctly and last longer.</p>

- Q: Are aluminum sheets suitable for food processing applications?

- Yes, aluminum sheets are suitable for food processing applications. Aluminum is known for its excellent thermal conductivity and corrosion resistance, making it ideal for food industry processes such as cooking, baking, and packaging. Additionally, aluminum is a lightweight and cost-effective material that can be easily formed into various shapes and sizes, making it convenient for food processing equipment and utensils.

- Q: how would you use aluminum to extract silver from film?just ideas please

- The silver in film is part of a silver salt (silver halides.) It is a very very small amount, probably less than 1 cent worth per roll. You would be a lot better off selling the film than trying to extract the silver from it. If you are hell bent on it, the first step is to expose the film to light. This will break the silver from the halides. Then you can go about trying to figure out how to get the silver apart from the film. I am sure it is possible, but it would involve a lot of work. I imagine you you would spend about $100 on ever $1 worth of silver you could extract.

- Q: Can 101 aluminum sheets be bonded to other materials?

- Indeed, it is possible to bond 101 aluminum sheets with other materials. Aluminum demonstrates remarkable versatility in its capability to be bonded with a vast array of substrates through diverse bonding techniques. Several commonly employed methods for bonding aluminum sheets to other materials comprise adhesive bonding, mechanical fastening, welding, and brazing. The selection of a specific bonding technique hinges upon factors such as the composition of the material to be bonded with aluminum, the desired strength of the bond, and the intended application. Nonetheless, it is crucial to ensure compatibility between the aluminum sheets and the other materials to guarantee the establishment of a robust and long-lasting bond.

- Q: What specific coatings or treatments are required for aluminum sheets to enhance their properties or protect them?

- <p>Special coatings or treatments for aluminum sheets may be needed depending on the application. Anodizing is a common treatment that enhances corrosion resistance and wear. For aesthetic purposes, aluminum can be painted or coated with a clear lacquer to maintain its appearance. Protective coatings like powder coating or electroplating can be used to improve durability and resistance to environmental factors. In certain industrial applications, aluminum sheets may be treated with specific coatings to enhance thermal or electrical conductivity. The choice of coating or treatment depends on the specific requirements of the project, such as resistance to weather, chemicals, or mechanical stress.</p>

- Q: On candle when candle flame is about 1.000 degrees celsius and melting point of aluminum is 660 degrees celsius.

- www.okorder /.. its doesnt burn burn u knw.it just becomes sorta britte.it becomes oxidised...u can got more infro there.try..i read it just now

- Q: Can aluminum sheets be used for lithographic printing plates?

- Yes, aluminum sheets can be used for lithographic printing plates. Lithographic printing is a method that uses the principle that oil and water do not mix. A lithographic printing plate is made of a metal base, typically aluminum, which is coated with a photosensitive layer. This layer is then exposed to light, creating a pattern that can be used for printing. Aluminum is a preferred material for lithographic printing plates due to its excellent properties. It is lightweight, yet strong and durable. It also has a smooth surface, which is crucial for achieving high-quality prints. Additionally, aluminum has good thermal conductivity, which aids in the fast drying of ink during the printing process. Furthermore, aluminum is easily processed and can be chemically treated to enhance its surface properties, such as making it more hydrophilic or hydrophobic. This allows for better control of the ink and water balance on the plate, resulting in sharper and more precise prints. In summary, aluminum sheets are commonly used for lithographic printing plates due to their desirable properties and suitability for the lithographic printing process.

- Q: What are the different surface treatments available for aluminum sheets?

- There are several different surface treatments available for aluminum sheets, each with its own unique properties and benefits. Some of the most common surface treatments for aluminum sheets include anodizing, painting, powder coating, and laminating. Anodizing is a popular surface treatment method that involves immersing the aluminum sheet in an electrolyte solution and passing an electric current through it. This creates an oxide layer on the surface of the aluminum, which enhances its corrosion resistance, improves durability, and can also provide decorative finishes in a variety of colors. Painting is another common surface treatment option for aluminum sheets. It involves applying a layer of paint onto the surface of the sheet, which not only enhances its aesthetics but also provides protection against corrosion and environmental elements. Painting allows for a wide range of colors and finishes, making it a versatile option for various applications. Powder coating is a technique where a dry powder is electrostatically applied to the aluminum sheet and then cured under heat, creating a durable and attractive finish. Powder coating offers excellent resistance to weathering, chemicals, and UV rays, making it suitable for outdoor applications. It also provides a wide range of color options and can be applied to achieve various textures and finishes. Laminating is a surface treatment process that involves bonding a thin layer of a different material, such as plastic or wood, onto the aluminum sheet. This not only enhances the aesthetics but also provides additional properties like scratch resistance, increased strength, and insulation. Laminating can offer a wide variety of finishes and textures, allowing for customization and versatility in design. These are just a few examples of the various surface treatments available for aluminum sheets. The choice of treatment depends on the specific requirements of the application, desired aesthetics, durability, and environmental factors. Consulting with a professional or supplier can help determine the most suitable surface treatment option for a specific project or application.

- Q: Are aluminum sheets suitable for mold making?

- Indeed, aluminum sheets prove to be a fitting option for mold making. Renowned for its lightweight nature, durability, and remarkable heat conductivity, aluminum emerges as a favored material for mold creation. These remarkable attributes render it suitable for molding processes, whether they involve low temperatures or high temperatures. Furthermore, aluminum lends itself well to machining and can be effortlessly shaped into intricate forms, enabling the production of elaborate molds. Its resistance to corrosion further guarantees the molds' durability. In essence, owing to their adaptability and dependability, aluminum sheets enjoy extensive employment in the realm of mold making.

Send your message to us

Aluminum Sheets Hawaii - Color Coated Aluminium Coils Polyester Coating AA3004

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords