Aluminum Coil Car Brushed Coated Aluminum Coils for Metal Wall ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Structure of Brushed Coated Aluminium Coils for Metal Wall ACP Description

• Product: Aluminim coils

• Application:

corrugated roofs, outer walls, ovens, electrically controlled cabinets.

household appliances, transportation, base plate, color coating.

industrial freezers in the residential and industrial buildings.

refrigerator backplane, gas stove, air conditioner, microwave, LCD border.

• Advantage: Full production line with all kinds of coils supply

2. Main Features of the Brushed Coated Aluminium Coils for Metal Wall ACP

• Our goods quality is top, the surface is smooth, and every steel coil

• No Joint, No Bends, no spots, no roller marks.

• MTC will be provided with goods, third part inspection is acceptable, for example, SGS, BV. Etc

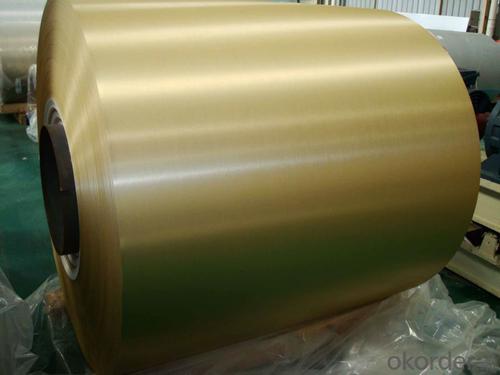

3. Brushed Coated Aluminium Coils for Metal Wall ACP Images

4. Brushed Coated Aluminium Coils for Metal Wall ACP Specification

Alloy | AA1050/1100/3003/3005/3105/5005/5052 etc |

Thickness | 0.03mm—4.0mm |

Width | 10mm—1600mm |

Coating | PVDF, PE |

Coatingthickness | Usually16-25 micron, could be 33-40 micron |

Color | According to Ral |

Standard | ASTM-B 209 GB/3008-2006 |

Usage/ApplicationsCoated Aluminum Coil/Sheet | Constructionand decoration, electronic appliances, lighting decoration, air-condition airpipe, sandwich panels and drainage, etc |

5.FAQ of Brushed Coated Aluminium Coils for Metal Wall ACP

We have organized several common questions for our clients,may help you sincerely:

① How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

②Can you guarantee the quality of the products?

We are responsible for the quality of materials to get a long-term cooperation with clients in a reasonable period of time and we are glad to arrange and coordinate any third party inspection for you.

③What is the delivery time after purchase?

35 day after receiving client’s deposit or correct LC

- Q: a) Although Aluminium is a reactive metal, it is used to make door frames and window frames.b) Although Aluminium conducts heat, it is used to make blankets, which are good thermal insulators.

- a] AL is used to make frames because it is light, not costly and strong.

- Q: Are aluminum coils suitable for construction purposes?

- <p>Yes, aluminum coils can be used for construction. They are valued for their lightweight, corrosion resistance, and high strength-to-weight ratio, making them ideal for applications such as roofing, facades, and structural components. Aluminum's malleability allows for easy shaping and forming, which is beneficial in various construction projects. It's also sustainable due to its recyclability, reducing environmental impact.</p>

- Q: Do aluminum coils require any special maintenance?

- To ensure aluminum coils perform at their best and last longer, regular maintenance is necessary, just like any other HVAC system component. While they don't need any special maintenance, attention and care are still required for efficient functioning. Maintenance tasks for aluminum coils include cleaning, inspection, and occasional straightening. Cleaning the coils is crucial to remove accumulated dirt, dust, and debris that can hinder heat transfer and restrict airflow, reducing the system's overall efficiency. Soft brushes or vacuum cleaners can be used for this task, taking care not to damage the fins and coils. Regular inspection is necessary to identify corrosion, leaks, or damage on the coils. Addressing these issues promptly can prevent further deterioration and costly repairs. Checking for bent or damaged fins and straightening them if needed is recommended to maintain proper airflow. Additionally, keeping the surrounding area clear of debris or vegetation is essential to prevent obstruction of airflow, increased energy consumption, and potential compressor damage. Regularly trimming vegetation and maintaining a clean area will help the coils perform optimally. Lastly, it is advisable to have a professional HVAC technician perform annual maintenance on the HVAC system, including the aluminum coils. They can conduct a thorough inspection, use specialized equipment for cleaning, check refrigerant levels, and ensure the system operates at its peak performance. In conclusion, regular maintenance including cleaning, inspection, and occasional straightening is necessary for optimal performance, damage prevention, and extended lifespan of aluminum coils.

- Q: Are there any specific regulations or standards for aluminum coil production?

- Yes, there are specific regulations and standards for aluminum coil production. These regulations and standards are put in place to ensure the quality, safety, and sustainability of the production process. One of the most important standards for aluminum coil production is the American Society for Testing and Materials (ASTM) International standard. ASTM B209 is the standard specification for aluminum and aluminum-alloy sheet and plate, which includes the requirements for aluminum coil production. This standard specifies the chemical composition, mechanical properties, and other technical requirements that the aluminum coil must meet. In addition to ASTM standards, there are also regulations and standards set by regulatory bodies such as the International Organization for Standardization (ISO) and the Occupational Safety and Health Administration (OSHA). ISO 9001 is a widely recognized standard for quality management systems, and ISO 14001 is for environmental management systems. These standards provide guidelines and requirements for the production process to ensure quality, environmental responsibility, and worker safety. Furthermore, specific regulations may vary by country or region. For example, in the United States, the Environmental Protection Agency (EPA) regulates the emissions and waste disposal associated with aluminum coil production through the Clean Air Act and the Resource Conservation and Recovery Act (RCRA). These regulations aim to minimize the environmental impact of the production process. Overall, the regulations and standards for aluminum coil production are in place to uphold the quality, safety, and environmental sustainability of the industry. Compliance with these regulations and standards is essential for manufacturers to ensure that their products meet the required specifications and are produced in a responsible manner.

- Q: What are the potential applications of stucco-embossed aluminum coils?

- Stucco-embossed aluminum coils offer a multitude of potential uses due to their distinct properties and attractive appearance. Here are some possible applications for stucco-embossed aluminum coils: 1. Construction: Stucco-embossed aluminum coils are commonly employed in the construction sector for cladding and roofing purposes. The textured pattern strengthens and enhances the durability of the aluminum, making it suitable for external applications. It can be utilized on both commercial and residential buildings to provide a visually pleasing and long-lasting finish. 2. Insulation: Stucco-embossed aluminum coils can also serve as insulation material. The textured surface increases the material's surface area, thereby improving its thermal conductivity. This makes it an excellent choice for applications where heat transfer needs to be regulated, such as HVAC systems or refrigeration units. 3. Appliances: The manufacturing of various appliances often incorporates stucco-embossed aluminum coils. The textured surface not only adds visual interest but also provides a robust and easy-to-clean finish. It can be used in the production of kitchen appliances like refrigerators, dishwashers, and ovens, as well as other household appliances like air conditioners or water heaters. 4. Transportation: Stucco-embossed aluminum coils also find applications in the transportation industry. The textured surface enhances traction, making it suitable for vehicle flooring and decking in buses, trains, and ships. It is also used for decorative purposes in the interior and exterior parts of automobiles, imparting a stylish and modern appearance. 5. Packaging: Stucco-embossed aluminum coils can be utilized in the packaging industry. The textured surface adds strength and rigidity to the material, making it ideal for manufacturing durable containers, trays, and packaging materials. It is suitable for food and beverage packaging, pharmaceutical packaging, and various other applications where a sturdy and visually appealing packaging solution is required. In conclusion, the uses for stucco-embossed aluminum coils are diverse and adaptable. From construction to insulation, appliances to transportation, and packaging to various other industries, stucco-embossed aluminum's unique properties and attractive appearance make it a popular choice for a wide range of applications.

- Q: What are the common methods of joining aluminum coils together?

- Common methods of joining aluminum coils together include welding, soldering, adhesive bonding, and mechanical fastening. Welding is a popular method that uses heat to melt the aluminum and join the coils together. Soldering involves using a lower melting point filler metal to bond the coils. Adhesive bonding uses adhesives or glues to create a strong bond between the coils. Mechanical fastening involves using screws, bolts, or other mechanical devices to hold the coils together.

- Q: What specific conditions or considerations need to be taken into account when utilizing aluminum coils in high-temperature settings?

- <p>When using aluminum coils in high-temperature environments, it's crucial to consider the material's melting point, which is around 660掳C (1220掳F). Ensure that the operating temperature does not exceed this threshold to avoid deformation or failure. Additionally, aluminum's strength and conductivity can be affected by high temperatures, so it's important to account for potential changes in performance. Protective coatings or treatments may be necessary to prevent oxidation and maintain the coil's integrity. Always consult material specifications and consult with material science experts to determine the suitability of aluminum coils for specific high-temperature applications.</p>

- Q: Can aluminum coils be used in high-pressure or high-temperature environments?

- No, aluminum coils are not suitable for high-pressure or high-temperature environments as they have lower strength and melting points compared to other materials.

- Q: How do aluminum coils contribute to lightweight construction?

- Due to its properties as a metal, aluminum plays a crucial role in lightweight construction. Its low density sets it apart from other metals like steel or copper, making it significantly lighter. When formed into coils, aluminum increases its surface area, resulting in more efficient heat transfer and distribution. The utilization of aluminum coils in various industries such as automotive, aerospace, and construction leads to a notable reduction in overall weight. This reduction offers several advantages, including enhanced fuel efficiency in vehicles, increased payload capacity in aircraft, and easier handling and installation in construction projects. Furthermore, the lightweight nature of aluminum coils enables designers and engineers to develop more innovative and energy-efficient designs. With less weight to support, thinner and lighter materials can be used for other components, resulting in additional weight savings. This not only saves costs during manufacturing and transportation but also reduces environmental impact. Moreover, aluminum coils possess excellent corrosion resistance, making them ideal for outdoor applications. Their ability to resist rust and corrosion adds to their durability and longevity, ensuring that lightweight structures made with aluminum coils can withstand harsh environmental conditions. In conclusion, aluminum coils contribute significantly to lightweight construction by providing a durable and lightweight material. This enables designers and engineers to create more efficient and sustainable structures, vehicles, and products. The use of aluminum coils not only reduces the weight of the overall construction but also offers benefits such as improved fuel efficiency, increased payload capacity, and cost savings.

- Q: Can aluminum coils be used in marine applications?

- Yes, aluminum coils can be used in marine applications. Aluminum is a corrosion-resistant metal that provides excellent durability and strength, making it suitable for various marine environments. It is commonly used in boat building, marine equipment, and other marine applications due to its lightweight nature and resistance to saltwater corrosion.

Send your message to us

Aluminum Coil Car Brushed Coated Aluminum Coils for Metal Wall ACP

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords