Hot-dip Aluzinc Steel Coil From Chinese Shandong

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 35 m.t.

- Supply Capability:

- 22222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of the Hot-dip Aluzinc Steel:

Hot-dip aluzinc steel structure is composed of aluminum-zinc alloy, consisting of 55% aluminum, 43% zinc and 2% at 600 ℃ silicon solidification temperature and composition, the entire structure is made of aluminum - iron - silicon - zinc, to form a dense quaternary crystals an alloy.

Hot-dip aluzinc steel has many excellent features: strong corrosion resistance, is three times the pure galvanized sheet; zinc surface with beautiful flowers, can be used as a building outside board.

2.Applications of hot-dip aluzinc steel:

1)Building: roof, walls, garages, soundproof walls, pipes and modular housing.

2)Automotive: muffler, exhaust pipes, wiper accessories, fuel tank, truck boxes, etc.

3)Appliances: refrigerator back, gas stove, air conditioners, microwave oven, LCD frame,

4)CRT-proof band, LED backlight, electrical cabinets, etc.

5)Farm: barn, sheds, silos, piping and other greenhouse.

6)Other: breaking heat insulation cover, heat exchangers, dryers, warm water, etc.

3.Main Features of the Hot-dip Aluzinc Steel:

• Excellent corrosion resistance

• High temperature oxidation resistance

• High hot reflectance

• Good manufacturability

•Beautiful appearance

•Surface coating

•Cost-effective

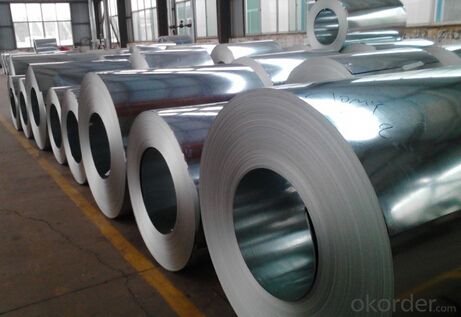

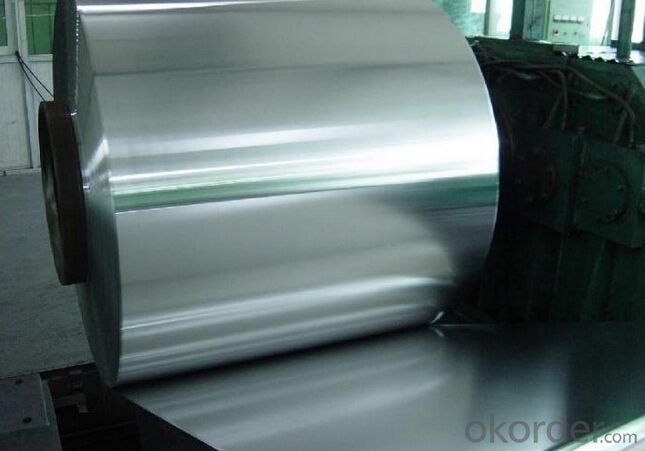

4.Hot-dip Aluzinc Steel Images

5.Hot-dip Aluzinc Steel Specification

AVAILABLE SPECIFICATION | HOT-DIP ALUZINC STEEL COILS |

THICKNESS | 0.16mm-3.5mm |

WIDTH | 1250mm MAX |

COATING MASS | 30 g/ m2-185 g/ m2 |

SPANGLE | Regular Spangle, Minimized Spangle, Zero Spangle |

SURFACE TREATMENT | Chromated / non-chromated, Oiled / non-oiled, Anti Finger Print |

COIL INNER DIAMETER | 508mm or 610mm |

HOT-DIP ALUZINC STEEL COILS | |||

COMMERCIAL QUALITY | ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 |

STRUCTURE STEEL | SS GRADE 230 SS GRADE 255 SS GRADE 275 SS GRADE 340 SS GRADE 550 | S220GD+AZ S250GD+AZ S280GD+AZ S320GD+AZ S350GD+AZ S550GD+AZ | SGLC400 SGLC440 SGLC490 SGLC570 |

6.FAQ of Hot-dip Aluzinc Steel

We have organized several common questions for our clients,may help you sincerely:

1) What advantages does your company have?

Cement : Annual capacity of 400 million tons, No. 1 in the world

Fiberglass: Annual capacity of 1 million tons fiberglass, No. 1 in the world.

Composite Materials — Carbon Fiber: Annual capacity of 10,000 tons PAN precursor and 4,000 tons carbon fiber, No. 1 in China

Composite Materials — Rotor Blade: Annual production capacity of 15,000 pieces, No.1 in China, Top3 worldwide

Glass: CNBM owns about 20 modern float glass product`ion lines, With annual capacity of 10 million square meters glass.

Light Weight Building Materials: Annual capacity of 1.65 billion square meters of gypsum board, No. 1 in the world.

Commercial concrete: Annual capacity of 0.35 billion cubic meters, No. 1 in the world.

Refractory Material: Annual capacity of 40,000 tons casting refractory, No.1 in the world.

2) What advantages do your products have?

Firstly, our base material is of high quality, Their performance is in smooth and flat surface,no edge wave ,good flexibility.

Secondly, high quality zinc ingoats, 97.5% zinc,1.5% silicon,1% others, the same zinc coating measured by metal coating thickness or by zinc weight

Thirdly, high precision: Tolerance strictly according to ASTM or JISG standard even more rigid.

We have full stes of testing equipment(for t best, cupule,chromatism,salt spray resistance, etc) and professional engineers.

3) Could you let me approach about your company in Dubai?

Located at Jebel Ali Free Zone in Dubai, CNBM Dubai Logistics Complex is adjacent to -Jebel Ali sea port-the largest port in UAE and Al Maktoum Airport-the largest airport in the world, which covers an area of 50,000 square meters, including an fully enclosed warehouse by 10,000 square meters, an open yard by 25000 square meters, and 13 standard unloading platform. CNBM Dubai Logistics Complex formally put into operation on August 1, 2013. Dubai Logistics Complex will commit itself to build the most professional and most influential building materials distribution center of China’s building materials industry in the UAE and throughout the Middle East and Africa.

- Q: What are the different methods for removing coatings from steel strips?

- There are several methods available for removing coatings from steel strips, each with its own advantages and disadvantages. Some common methods include mechanical, chemical, thermal, and abrasive methods. Mechanical methods involve physically scraping or peeling off the coating from the steel strip. This can be done using tools such as scrapers, chisels, or brushes. While this method may be effective for thin or loose coatings, it may not be suitable for thicker or tougher coatings. Chemical methods use chemical agents to dissolve or loosen the coating from the steel strip. These chemicals can be applied through immersion, brushing, or spraying. The choice of chemical will depend on the type of coating being removed. However, care must be taken to ensure that the chemicals used do not damage the steel strip or pose any health risks. Thermal methods involve using heat to burn off or melt the coating from the steel strip. This can be done through methods such as flame or infrared heating. Thermal methods are effective for coatings that can be easily melted or burned, but may not be suitable for coatings that are more resistant to heat. Abrasive methods involve using abrasive materials, such as sandpaper, blasting media, or wire brushes, to physically remove the coating from the steel strip. This method is effective for tougher coatings and can be used to achieve a smooth and clean surface. However, it may be time-consuming and labor-intensive. In some cases, a combination of these methods may be used to remove coatings from steel strips. It is important to consider factors such as the type and thickness of the coating, the condition of the steel strip, and the desired end result when choosing the appropriate method for coating removal. Additionally, safety precautions should always be followed to protect the workers and the environment from any potential hazards associated with the chosen method.

- Q: How are steel strips processed for surface plating?

- To ensure proper adhesion and a smooth finish, the surface plating of steel strips involves a series of steps. These steps typically include: 1. Thoroughly cleaning the steel strips to eliminate any surface contaminants like dirt, grease, or other substances. This is accomplished by employing a combination of chemical cleaning agents and mechanical scrubbing. 2. Treating the cleaned steel strips to prepare their surface for plating. This can involve various techniques such as pickling, acid etching, or mechanical roughening. The objective is to create a roughened surface that promotes better adhesion of the plating material. 3. Immersing the prepared steel strips in an electrolyte bath containing the desired plating material. An electric current is then applied to the bath, causing the plating material to adhere to the steel strips. The plating material can be zinc, nickel, chromium, cadmium, or other metals depending on the desired properties and appearance. 4. Subjecting the electroplated steel strips to additional treatments to enhance the properties of the plating. These treatments may include heat treatment, passivation, or the application of a protective coating. These steps contribute to improving the plating's durability, corrosion resistance, and aesthetic appearance. 5. Implementing quality control measures throughout the entire process to ensure the plating meets the required specifications. Visual inspection, thickness measurement, adhesion tests, and other testing methods are employed to guarantee high-quality plating that meets the desired standards. By following these steps, steel strips can undergo effective surface plating, resulting in enhanced durability, corrosion resistance, and an appealing finish.

- Q: What is the difference between hot-rolled and cold-rolled steel strips?

- The main difference between hot-rolled and cold-rolled steel strips lies in the manufacturing process. Hot-rolled steel strips are produced at high temperatures, resulting in a rougher and less precise surface finish. On the other hand, cold-rolled steel strips are processed at lower temperatures, which yields a smoother and more precise surface finish. Additionally, hot-rolled steel strips are generally cheaper and easier to shape, while cold-rolled steel strips offer higher strength and better dimensional accuracy.

- Q: How do steel strips perform in magnetic fields?

- Steel strips are typically not magnetic, meaning they do not attract or repel when placed in a magnetic field. However, certain types of steel strips can be made magnetic through a process called magnetization.

- Q: How is the hardness of steel strips measured?

- The hardness of steel strips is typically measured using a variety of methods, including the Rockwell hardness test, Vickers hardness test, or the Brinell hardness test. These tests involve applying a specific amount of force to the surface of the steel strip and measuring the depth or size of the resulting indentation. The hardness value obtained from these tests provides an indication of the steel strip's resistance to deformation and wear.

- Q: How are steel strips plasma cut?

- Steel strips are plasma cut using a high-temperature plasma arc that is directed towards the steel surface. This creates a concentrated and intense heat source, melting the steel and allowing it to be cut smoothly and accurately.

- Q: What are the typical thicknesses of galvanized steel strips?

- The typical thicknesses of galvanized steel strips range from 0.2 to 6 millimeters, depending on the specific application and industry requirements.

- Q: What is a steel strip?

- A steel strip is a flat and thin piece of steel that is typically produced through a process called hot rolling or cold rolling. It is formed by passing a heated or cooled steel billet through a series of rollers, which gradually reduce its thickness and shape it into a long and narrow strip. Steel strips are commonly used in various industrial applications due to their strength, durability, and versatility. They can be found in products such as automotive parts, construction materials, electrical appliances, and packaging materials. The strip's width can vary based on its intended use, and it can also be further processed or treated to enhance certain properties or achieve specific characteristics, such as surface finish, hardness, or corrosion resistance. Overall, steel strips are essential components in many manufacturing processes and play a crucial role in numerous industries.

- Q: Can steel strips be used for making electrical connectors in electronic devices?

- Yes, steel strips can be used for making electrical connectors in electronic devices. However, steel strips may not be the optimal choice as they are not as conductive as other materials such as copper or gold. Copper or gold are commonly preferred for electrical connectors due to their excellent conductivity, low resistance, and corrosion resistance.

- Q: How are steel strips used in the manufacturing of electrical components?

- Due to their various properties and benefits, steel strips find common usage in the manufacturing of electrical components. Typically crafted from high-quality steel alloys, these strips are cut into desired shapes and sizes to cater to specific applications. One of the primary applications of steel strips in electrical component manufacturing involves the creation of magnetic cores. These cores are essential elements in transformers, inductors, and other electrical devices that require efficient energy transfer. The steel strips are meticulously stacked and laminated to minimize eddy currents and enhance magnetic performance. This lamination structure aids in reducing energy losses and improving the overall efficiency of the electrical component. Furthermore, steel strips often serve as a solid and stable base or support material for electrical contacts and connectors. These components necessitate a firm foundation to ensure proper electrical conductivity and secure connections. Steel strips offer excellent mechanical strength and stability, making them an ideal choice for such applications. In addition, steel strips can be employed for shielding purposes in electrical components. The interference caused by electromagnetic waves (EMI) can negatively impact the performance of sensitive electronic devices. By incorporating steel strips into the design, manufacturers can create an effective barrier against EMI, safeguarding the electrical component from external interference and ensuring its proper functioning. Moreover, steel strips are also utilized in the manufacturing of electrical springs and contacts. These components demand specific mechanical properties, including high tensile strength, resilience, and durability. Steel strips possess these attributes and can be easily molded into the desired shape, making them well-suited for applications that require repetitive motion or reliable electrical connections. In conclusion, steel strips play a crucial role in the manufacturing of electrical components. They are utilized for creating magnetic cores, providing a stable foundation for contacts and connectors, shielding against electromagnetic interference, and producing springs and contacts with desired mechanical properties. With their versatility and reliability, steel strips significantly contribute to the overall performance and efficiency of electrical devices.

Send your message to us

Hot-dip Aluzinc Steel Coil From Chinese Shandong

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 35 m.t.

- Supply Capability:

- 22222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords