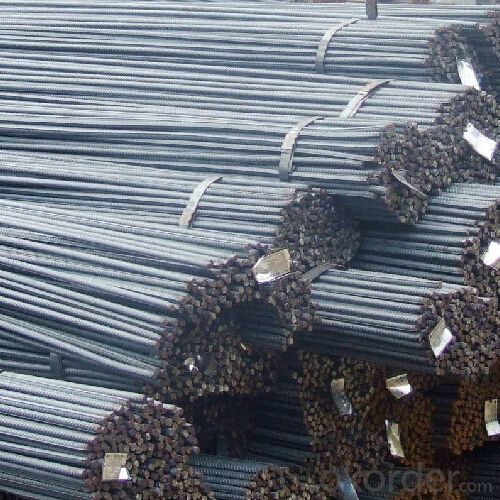

This World's Best Rebar From Chines Mill

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 22222 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Wire Rod Steel for Construction Description

the wire rod steel for construction that we offer have been used in civil construction work for years.

2.Main Features of the Wire Rod Steel for Construction

fasteners, bolts, rivets, screws,

general purpose wires,

electrode wires, industrial wires, agriculture wires,

bush wires, chain rivet wires,

detonator wire,

Umbrella ribs, upholstery wires, cycle spokes, needle wires, heald wires, staple pin Wire, safety pin wires

ACSR wires, earth wires,

tyre and hose reinforcement wires,

prestressed concrete wire, springs and rope wires,

card clothing wires,

vineyard wires,

ball bearing quality

Automobile parts like screw, fasteners, bush, spline, socket, connecting rod, shaft, gear, rivets, engine shaft, connecting rod, spindles, gears, etc.

3.Wire Rod Steel for Construction Images

4.Wire Rod Steel for Construction Specification

Grade | Chemical Composition(%) | |||||

C | Mn | Si | S | P | B | |

SAE1006B | 0.03~O.07 | ≤0.32 | ≤0.30 | ≤0.045 | ≤0.040 | >0.0008 |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation(%) | ||||

250-280 | 350-380 | ≥32 | ||||

Grade | Chemical Composition(%) | |||||

C | Mn | Si | S | P | B | |

SAE1008B | 0.10max | 0.3~O.50 | 0.15max | 0.050max | 0.040 max | 0.0008 min |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation(%) | ||||

≥195 | 315-430 | ≥30 | ||||

5.FAQ of Wire Rod Steel for Construction

1.What is your minimum order quantity ?

Our MOQ is 500mt .

2.Please tell me the daily output and wire rod mill’s brand ?

Our daily output is 4000mt/day and our rolling mill from Germany’s SMS MEER

3.Which countries are your main sales?

Thanks to the professional international trade team, solid distribution channel and long – term cooperation customers, our market share in overseas realizes a tremendous growth, now we already became a main player in Middle East and South East Asia. Meanwhile, we are also the biggest supplier of Pre-painted galvanized steel coil in Philippines, Saudi Arabia, United Arab Emirates, Iran, Sudan etc.

- Q: What are the dimensional inspection methods for steel strips?

- Some common dimensional inspection methods for steel strips include calipers, micrometers, optical comparators, laser scanners, and coordinate measuring machines (CMMs). These tools are used to measure dimensions such as thickness, width, length, and straightness of the steel strips to ensure they meet the required specifications.

- Q: How are steel strips used in the production of metal packaging?

- Steel strips are commonly used in the production of metal packaging as they serve as the primary material for manufacturing cans, containers, and lids. These strips are typically cut, shaped, and welded into the desired form to create the necessary structure for packaging various products such as food, beverages, cosmetics, and chemicals. The steel strips provide strength, durability, and protection to the packaged contents, ensuring their integrity during storage and transportation. Additionally, these strips can be coated or decorated to enhance the visual appeal of the packaging, making them an essential component in the metal packaging industry.

- Q: Can steel strips be used in the production of power generation equipment?

- Certainly, the utilization of steel strips is applicable in the manufacturing process of power generation equipment. Steel, being an extremely versatile and long-lasting material, finds extensive employment across multiple industries, including power generation. The utilization of steel strips enables the production of diverse components, such as turbine blades, generator frames, and electrical enclosures, to name a few. The exceptional strength and corrosion resistance of steel render it an optimal choice for fulfilling these specific requirements. Moreover, the malleability of steel strips permits effortless shaping and sizing, facilitating customization and optimization of power generation equipment.

- Q: Are steel strips suitable for the production of cutlery or kitchen utensils?

- Yes, steel strips are suitable for the production of cutlery or kitchen utensils. Steel is a durable and strong material that can withstand the demands of daily use in kitchens. It is resistant to corrosion and can be easily shaped into various utensil designs. Steel strips provide the necessary strength and flexibility required for creating high-quality cutlery and kitchen utensils.

- Q: How are steel strips processed for deburring?

- Various techniques are employed to deburr steel strips, depending on specific requirements. One commonly utilized approach involves mechanical deburring, where the strips are passed through specialized machines equipped with rotating brushes or abrasive wheels. These brushes or wheels effectively eliminate burrs by rubbing against the strip's surface, resulting in the smoothing out of any rough edges or protrusions. Another technique, known as vibratory deburring, entails placing the steel strips into a vibratory bowl or tub alongside abrasive media. Through consistent friction caused by vibration, the media rubs against the strips, effectively removing burrs. This method proves highly useful for deburring intricate or delicate shapes. Chemical deburring presents an alternative option, whereby the steel strips are immersed in a chemical bath containing a deburring agent. The agent dissolves the burrs, resulting in smooth and even strip surfaces. This method is commonly employed for deburring hard-to-reach areas or parts with intricate geometries. Additionally, advanced laser deburring employs laser technology to accurately remove burrs from steel strips. The laser beam is directed at the burrs, melting or vaporizing them, thus creating a clean and burr-free surface. This method is exceptionally precise and efficient, making it suitable for high-precision applications. Ultimately, the choice of deburring method for steel strips depends on factors such as part complexity, desired precision levels, and production volume. By selecting the most appropriate technique, manufacturers can effectively eliminate burrs and ensure the quality of their steel strips.

- Q: What is the cost of steel strips?

- The cost of steel strips can vary depending on factors such as the type of steel, thickness, width, and quantity needed. It is best to contact a supplier or check with local steel distributors for specific pricing information.

- Q: How are steel strips used in the manufacturing of automotive body panels?

- Steel strips are used in the manufacturing of automotive body panels as they provide a strong and durable material for creating the outer shell of vehicles. These strips are shaped, cut, and formed into panels that can be welded or bolted together to construct the body of the car, providing structural integrity and protection for the occupants.

- Q: How are steel strips used in the production of automotive fasteners?

- Steel strips are used in the production of automotive fasteners as they provide the necessary strength and durability required for these components. These steel strips are shaped and formed into various types of fasteners such as screws, bolts, and nuts. The uniformity and consistency of the steel strip ensure that the fasteners have the desired mechanical properties, enabling them to securely hold automotive components together.

- Q: What are the different coating options available for steel strips?

- There are several coating options available for steel strips, each providing unique properties and benefits. Some of the common coating options include: 1. Zinc Coating: Zinc coating, often referred to as galvanization, is one of the most popular options. It provides excellent corrosion resistance and protects the steel from rust and other environmental factors. Zinc-coated steel strips are commonly used in outdoor applications or in environments with high humidity. 2. Paint Coating: Paint coatings provide an aesthetic appeal along with corrosion protection. Different types of paints, such as epoxy, polyurethane, or acrylic, can be applied to steel strips to provide varying degrees of durability and resistance to chemicals, UV rays, and other environmental factors. Paint coatings are commonly used in architectural, automotive, and industrial applications. 3. Polymer Coating: Polymer coatings, such as polyvinylidene fluoride (PVDF) or silicone polyester, are applied to steel strips to enhance their weather resistance, durability, and aesthetic appeal. These coatings are often used in building and construction, automotive, and appliance industries. 4. Epoxy Coating: Epoxy coating provides excellent corrosion resistance and chemical protection. It is commonly used in industries where the steel strips are exposed to harsh chemicals or corrosive environments, such as oil and gas, marine, or chemical processing industries. 5. Tin Coating: Tin coating, also known as tin plating, provides a decorative and corrosion-resistant finish to the steel strips. It is commonly used in the manufacturing of food cans, beverage cans, and other packaging materials. 6. Aluminum Coating: Aluminum coating, also known as aluminum-zinc alloy coating or Aluzinc, provides excellent corrosion resistance and heat reflectivity. It is often used in roofing and cladding applications. 7. Phosphate Coating: Phosphate coating is a conversion coating that improves the adhesion and corrosion resistance of steel strips. It is commonly used as a pre-treatment before applying other paint or coating systems. These are just a few examples of the various coating options available for steel strips. The choice of coating depends on the specific application requirements, budget, and desired performance characteristics.

- Q: How are steel strips used in the production of automotive parts?

- Steel strips are commonly used in the production of automotive parts due to their strength, durability, and versatility. These strips are typically made from high-quality steel alloys that are specifically designed to meet the demanding requirements of the automotive industry. One of the primary applications of steel strips in automotive part production is in the manufacturing of body panels. These panels, such as doors, hoods, fenders, and roofs, require materials that can withstand impacts, resist corrosion, and provide structural integrity. Steel strips are an ideal choice for these components as they offer excellent strength-to-weight ratio, ensuring the safety and performance of the vehicle. Steel strips are also used in the production of structural components like chassis frames and suspension systems. These parts need to be able to handle heavy loads, endure harsh road conditions, and provide stability. Steel strips provide the necessary strength and rigidity to these components, ensuring the overall structural integrity of the vehicle. In addition to body panels and structural components, steel strips are employed in the production of smaller automotive parts as well. These include brackets, reinforcements, supports, connectors, and various other components that require high strength and dimensional accuracy. Steel strips can be easily cut, formed, and welded to create complex shapes and designs, making them a preferred material in the automotive industry. Furthermore, steel strips are often used in the production of safety-related automotive parts such as seatbelt buckles, door latches, and airbag components. These parts require materials that can withstand extreme forces and provide reliable performance in critical situations. Steel strips offer the necessary strength, toughness, and resistance to deformation, ensuring the safety of passengers in case of accidents. Overall, steel strips play a vital role in the production of automotive parts by providing strength, durability, and versatility. Their usage in body panels, structural components, smaller parts, and safety-related components contribute to the overall performance, safety, and longevity of vehicles.

Send your message to us

This World's Best Rebar From Chines Mill

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 22222 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords