Cold rolled grain oriented silicon steel wholesale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 62134 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Cold rolled sheet steel products are used in a wide variety of end applications such as appliances, automobiles - exposed as well as unexposed parts, electric motors, plumbing fixtures, drum manufacturing, shelving, furniture, doors, toolboxes, tubing products, unexposed construction products, as well as many other areas of manufacturing

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

| ||||

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc,

construction & building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving,

containers, drums

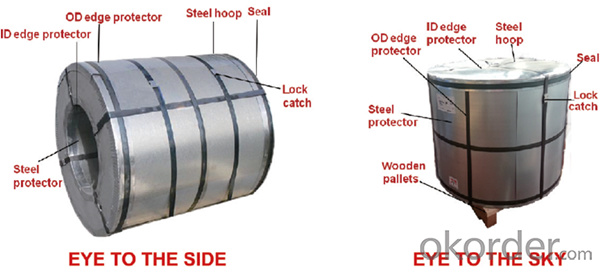

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order..

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: What temp does fire have to be to melt steel?

- There are different types of steel. Melting point of steel depends upon its contents. Generally the melting point of stell is above 1500 c.

- Q: What are the different coil slitting methods used for steel coils?

- There are three main coil slitting methods used for steel coils: rotary shear slitting, loop slitting, and oscillating slitting. Rotary shear slitting involves using rotating knives to cut the steel coil into narrower strips. Loop slitting is a process where the coil is looped through a series of rolls, and the desired width is achieved by adjusting the tension in the loop. Oscillating slitting is another method where the steel coil is passed through a set of oscillating blades, resulting in precise and high-speed slitting. These methods offer various advantages and are chosen based on the specific requirements of the steel coil slitting process.

- Q: Can steel coils be returned if they are damaged?

- Yes, steel coils can typically be returned if they are damaged. However, the return policy may vary depending on the supplier or manufacturer. It is advisable to contact the seller or review the terms and conditions of the purchase to determine the specific return policy for damaged steel coils.

- Q: How do steel coils contribute to the automotive industry?

- The automotive industry heavily relies on steel coils to manufacture different components and structures for vehicles. These coils are made from high-quality steel and undergo a series of processes, such as hot rolling, cold rolling, and annealing, to achieve the desired properties. One of the main applications of steel coils in the automotive industry is for producing body panels and frames. The strength and durability of steel make it an ideal material for these purposes, providing structural integrity and protection to the vehicle. Through a stamping process, steel coils are transformed into sheets, allowing manufacturers to create intricate shapes and designs for various vehicle models. Furthermore, steel coils are also utilized in the production of suspension systems, including springs and shock absorbers. The elasticity and resilience of steel enable these components to withstand the constant impact and weight of the vehicle, ensuring optimal performance and comfort for the driver and passengers. In addition, engine components like crankshafts, camshafts, and cylinder heads are manufactured using steel coils. These components require the strength and thermal resistance that steel provides, ensuring the efficient operation and longevity of the engine. Moreover, steel coils play a crucial role in the production of exhaust systems, which are essential for reducing emissions and noise levels. Steel's resistance to heat and corrosion make it an excellent material choice for exhaust pipes, mufflers, and catalytic converters, ensuring their durability and functionality. Overall, steel coils are indispensable in the automotive industry as they contribute to the manufacturing of various components and structures that are vital for the performance, safety, and longevity of vehicles. The high strength, durability, and versatility of steel make it the preferred material choice, enabling manufacturers to create reliable and efficient automobiles.

- Q: What are the different coil packaging machine configurations used for steel coils?

- There are various coil packaging machine configurations utilized for steel coils, each tailored to specific coil sizes, weights, and packaging needs. 1. The horizontal coil packaging machine is designed for smaller steel coils. It is typically equipped with a conveyor system that transports the coil horizontally throughout the packaging process. It may incorporate automatic coil centering, wrapping, and strapping features to guarantee secure and efficient packaging. 2. The vertical coil packaging machine is suitable for larger and heavier steel coils. It is designed to package coils in a vertical position and often includes a rotating arm or turntable for wrapping and securing the coil with strapping. Vertical machines have a higher throughput capacity and can handle coils of various sizes and weights. 3. The ring coil packaging machine is specifically designed for large and heavy steel coils. It comprises a rotating ring structure that surrounds the coil and moves up and down while wrapping and securing it with stretch film or other packaging material. Ring coil packaging machines are versatile, accommodating coils of different diameters and weights, making them suitable for various coil packaging requirements. 4. The eye-to-sky coil packaging machine is intended for steel coils that need to be packaged in an eye-to-sky orientation. It typically features a wrapping station that rotates the coil while applying stretch film or other packaging material. This configuration ensures proper protection and stability during transportation and storage. 5. The eye-to-horizontal coil packaging machine is designed for steel coils that need to be packaged in an eye-to-horizontal orientation. It includes a conveyor system that transports the coil horizontally while applying stretch film or other packaging material. Eye-to-horizontal machines can handle coils of different sizes and are designed to provide secure packaging for easy handling. In conclusion, the choice of coil packaging machine configuration depends on factors such as coil size, weight, packaging requirements, and production throughput. Different configurations offer distinct features and capabilities to ensure efficient and secure packaging of steel coils.

- Q: What are the quality standards for steel coil production?

- The quality standards for steel coil production typically include factors such as dimensional accuracy, surface finish, mechanical properties, chemical composition, and adherence to industry-specific standards and specifications. These standards ensure that the steel coils meet the required strength, durability, and performance criteria, and are suitable for various applications in industries like automotive, construction, and manufacturing.

- Q: what is the densest type of steel ? what is its density ?what is its tensile strength .

- Agree okorder . If you are really looking for higher density, go to copper or tungsten.

- Q: What are the different types of steel coil slitting machines?

- There are several different types of steel coil slitting machines, including manual slitters, semi-automatic slitters, and fully automatic slitters. Manual slitters require manual adjustment and operation, while semi-automatic slitters have some automated features but still require some manual intervention. Fully automatic slitters are the most advanced type, with fully automated controls and high-speed operation.

- Q: Why are steel saucepans and tea kettles covered with copper on the outside and the bottom? what r the goals of having high-quality pans that are thick and tea kettles that are thin walled?

- Stainless steel is less conductive than copper. However, steel will retain heat longer and thus be distributed more evenly. (hence the thick bottoms, but also for balance). Copper on tea kettles is ideal to bring water up to a boil rapidly but since your not really cooking food, temperature distribution or control doesn't really matter. Now if your cooking sensitive food, then it does matter. For example, the use of a double boiler is preferred for chocolates. Temperature and distribution is critical. As far as relatively inexpensive copper clad pots and pans such as Revereware? Well, I don't see a difference but perhaps they did some testing.

- Q: How are steel coils inspected for flatness?

- To ensure they meet the necessary standards, steel coils undergo a variety of methods and techniques to inspect their flatness. Trained inspectors visually examine the coil's surface for signs of waviness or unevenness, searching for visible defects like waves, buckles, or twists that could impact its flatness. Another approach involves using specialized equipment such as flatness gauges or profilometers to inspect the coil's flatness. These instruments measure the surface profile and provide detailed information about any deviations from the desired flatness. They can detect both local and overall flatness issues, offering a more precise assessment of the coil's quality. In addition to visual and instrumental inspections, physical tests can also be conducted to evaluate the flatness of steel coils. The "drape" test, for instance, involves draping the coil over a flat surface and measuring any noticeable gaps or unevenness. This test quickly identifies major flatness problems. Moreover, computerized analysis and simulation techniques are gaining popularity for inspecting the flatness of steel coils. These methods utilize advanced software to analyze the coil's surface data and generate comprehensive reports on its flatness characteristics. By comparing the actual surface profile with the desired specifications, these techniques provide a thorough assessment of the coil's flatness. Overall, the inspection of steel coils for flatness combines visual inspection, specialized equipment, physical tests, and advanced analysis techniques. These methods ensure that the coils meet the necessary flatness standards, which is essential for their successful application in industries such as automotive, construction, and manufacturing.

Send your message to us

Cold rolled grain oriented silicon steel wholesale

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 62134 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords