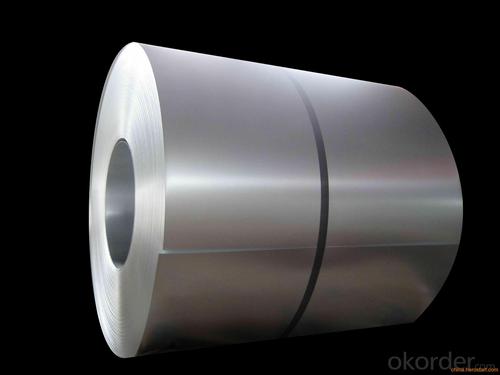

Cold Rolled Coil Strips/Galvanized Steel Coil Z275/Hot Dipped Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

cold rolled strips

1. width: 19-1500mm

2. thickness :0.2-3.0m,2.0-13.5mm

3.zinc coating:z60-z275

4.GB,JIS,ASTM,DIN,EN

cold rolled strips

Product Description

Brand : ZHCX | Standard: ASTM; ASTM; EN;GB | Grade:DX51D /DX52D/DX53D/ S250,280,320GD,Q195,Q235,etc. |

Thickness: 0.2-3.0mm 2.0-13.2mm | Width:19-1500mm | Length:Coil or upon request |

Zinc Coating: 40g- 275g/m2 | Surface: zero spangle, min spangle , regular spangle ,big spangle | Application: PPGI coil;construction,hardware, home appliances,interior decoration etc. |

Coil ID: 508-610mm | Coil Weight: 3-5 tons | Type : coil or sheet |

Packing: | 1.wooden case or wooden pallet 2.standard seaworthy packing | |

Delivery Time | Within 7-25 days after received the deposit | |

Brief Introduction

1. Prepainted Galvanized Steel Coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized steel sheets.

2. The base metal for Prepainted Galvanized Steel Coil is HDGI Steel. The finish coats of Prepainted Galvanized Steel Coil can be classified into groups as follows: polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

3. The production process has evolved from one-coating-and-one-baking to double-coating-and-double-baking, and even three-coating-and-three-baking.

4. The color of the Prepainted Galvanized Steel Coil has a very wide selection, like orange, cream-colored, dark sky blue, sea blue, bright red, brick red, ivory white, porcelain blue, etc.

5. The Prepainted Galvanized Steel Coil can also be classified into groups by their surface textures, namely regular prepainted sheets, embossed sheets and printed sheets.

Edit

Because there is no after annealing treatment, the hardness is very high (HRB greater than 90), mechanical processing performance is poor, only a simplebending process has less than 90 degree directional (direction perpendicular to the rolled).

3, use three

Edit

Hot rolled products with high strength and good toughness, easy processing and good forming can be excellent performance of welding, which is widely used in ships, cars, bridges, buildings, machinery, boiler, pressure vesselmanufacturing industry.

The scope of application:

(1) after annealing processing into the common cold;

(2) processing galvanized galvanized unit before the annealing treatment;

(3) the basic do not need to process the panel.

4 four, classification

Edit

Carbon steel plate, carbon plate, low alloy plate, ship plate, bridge plate, boiler plate, container plate etc.. Rolling hard volumes: under normal temperature,the hot pickling volumes of continuous rolling.

Hot rolled steel strip products include steel (roll) and the shear of steel plate.And steel (coils) can be divided into straight and finishes volume (the volume,smooth rolling and slitting roll).

- Q: Can steel sheets be used in corrosive environments?

- Corrosive environments necessitate careful consideration of the type of steel used and appropriate protective measures. Stainless steel, for instance, is known for its exceptional resistance to corrosion and ability to withstand harsh conditions. It contains chromium, which creates a protective oxide layer on the surface, preventing corrosion. Alternatively, galvanized steel involves applying a layer of zinc to the surface, forming a protective barrier against corrosion. Furthermore, one can enhance the resistance of steel sheets to corrosive elements by applying various coatings like epoxy, polyurethane, or paint. The selection of the right steel grade and protective coatings is crucial and should be based on the specific corrosive environment to ensure long-lasting performance. Regular inspections and maintenance are also imperative to promptly identify and address any potential signs of corrosion.

- Q: How do steel sheets perform in terms of fatigue resistance?

- Steel sheets are known for their outstanding fatigue resistance. Their high strength and durability allow them to endure repeated cyclic loading without experiencing significant damage or failure. This fatigue resistance is due to the material's capacity to absorb and distribute stress, effectively preventing the accumulation of cracks or fractures. Moreover, the fatigue resistance of steel sheets can be further enhanced through various heat treatment methods, like quenching and tempering, which improve their fatigue resistance properties. As a result, steel sheets are frequently chosen for applications where fatigue resistance is crucial, particularly in the automotive and aerospace industries, as they can endure prolonged and repeated loading without compromising their structural integrity.

- Q: Can steel sheets be used in food processing or pharmaceutical industries?

- Steel sheets are indeed applicable for use in the food processing and pharmaceutical industries. These industries often utilize stainless steel sheets because of their remarkable resistance to corrosion, their durability, and their hygienic properties. Stainless steel, known for being non-reactive and not releasing any harmful substances into food or pharmaceutical products, is frequently employed. Furthermore, its ease of cleaning and maintenance makes it a suitable option for applications that necessitate high levels of cleanliness and hygiene. Moreover, stainless steel sheets are capable of withstanding extreme temperatures and are resistant to impact and abrasion, making them an ideal choice for the food processing and pharmaceutical industries, where stringent quality and safety standards are crucial.

- Q: Can steel sheets be used in transportation applications?

- Yes, steel sheets can be used in transportation applications.

- Q: What are the different surface protection methods for steel sheets?

- There are several surface protection methods for steel sheets, including galvanizing, powder coating, painting, and epoxy coating. Galvanizing involves applying a layer of zinc to the steel surface to prevent corrosion. Powder coating is a process where a dry powder is applied electrostatically and then cured under heat, creating a durable and protective coating. Painting involves applying a liquid paint to the steel surface, providing a barrier against corrosion. Epoxy coating is a type of paint that is specially formulated with epoxy resins, offering excellent adhesion and chemical resistance.

- Q: Can the steel sheets be painted or coated?

- Yes, steel sheets can be painted or coated. Painting or coating steel sheets is a common practice in various industries to enhance the appearance, protect against corrosion, and improve durability. The steel surface should be properly cleaned and prepared before applying any paint or coating to ensure proper adhesion. Different types of paints or coatings can be used depending on the desired finish, environmental conditions, and the specific application. It is important to select the appropriate type of paint or coating that is compatible with the steel substrate and can withstand the intended use and exposure to chemicals, moisture, UV radiation, or other factors that may affect the performance and longevity of the coating.

- Q: Are steel sheets suitable for harsh weather conditions?

- Yes, steel sheets are highly suitable for harsh weather conditions. Steel is known for its durability and strength, making it an ideal material for withstanding extreme weather conditions such as high winds, heavy rain, snow, and even hail. Steel sheets are designed to be resistant to corrosion, rust, and degradation caused by prolonged exposure to harsh weather, making them long-lasting and reliable in any climate. Additionally, steel sheets can be coated with protective finishes, such as galvanized or painted coatings, to further enhance their resistance to weathering. This makes steel sheets a popular choice for various applications in harsh weather-prone areas, including roofing, siding, and outdoor structures, as they provide excellent protection and structural integrity even in the toughest weather conditions.

- Q: What are the different bending radius options for steel sheets?

- The bending radius options for steel sheets can vary depending on the thickness and type of steel being used. However, common bending radius options for steel sheets typically range from 0.5 times the thickness of the sheet to 2 times the thickness of the sheet.

- Q: Can steel sheets be used for construction formwork or molds?

- Yes, steel sheets can be used for construction formwork or molds, although they may not be as commonly used as other materials such as plywood or timber. Steel sheets are durable, strong, and can provide a smooth and even surface for casting concrete. They are particularly suitable for large-scale construction projects where formwork needs to withstand high pressures and loads. Steel sheets can be custom-designed and fabricated to meet specific project requirements, offering flexibility in shape, size, and configuration. However, it is important to consider the cost, weight, and availability of steel sheets compared to other formwork materials before making a decision.

- Q: Are the steel sheets resistant to scratching or abrasion?

- Yes, steel sheets are highly resistant to scratching or abrasion. Steel is known for its exceptional durability and strength, making it resistant to various forms of damage, including scratches and abrasions. The smooth and hard surface of steel sheets makes them less susceptible to scratches caused by sharp objects or rough surfaces. Additionally, the strong molecular structure of steel prevents it from easily wearing down or getting scratched, ensuring its longevity even in high-traffic or demanding environments. Overall, steel sheets are an excellent choice when it comes to resistance against scratching or abrasion.

Send your message to us

Cold Rolled Coil Strips/Galvanized Steel Coil Z275/Hot Dipped Steel Coil

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m.t.

- Supply Capability:

- 40000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords