Cold rolled carbon steel steel strip coils allibaba com

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 61450 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

These cold rolled steel coil/sheet grades have excellent formability, which facilitates cold forming operations, and are ideal for deep drawing. Our range of steels for cold forming offer excellent forming performance, due to the low scattering of their chemical composition and their mechanical properties, which guarantees processing consistency.

It is suited to formation by bending or drawing, which enables complex parts to be produced in good repeatable conditions and intended for indoor use.

Cold rolled sheet steel products are used in a wide variety of end applications such as appliances, automobiles - exposed as well as unexposed parts, electric motors, plumbing fixtures, drum manufacturing, shelving, furniture, doors, toolboxes, tubing products, unexposed construction products, as well as many other areas of manufacturing.

Standard and Grade :

Cold rolled steel coils | ||||

JIS G3141-2005 | EN10130-2006 | ASTM A1008-12a | ||

Commercial quality | SPCC | DC01 | CS Type A/B/C | |

Drawing quality | SPCD | DC03 | DS Type A/B | |

Deep drawing quality | SPCE SPCF(non aging) | DC04 | DDS | |

Extra deep drawing quality | SPCG(non aging) | DC05/06 | EDDS | |

| ||||

Application :

Automobile Industry, White Goods, Home Applicances, Oil & Air filters, semi product for coating with enamel or zinc,

construction & building sector, air-conditioning, furniture, radiators, tubes, profiles, mechanical construction, shelving,

containers, drums

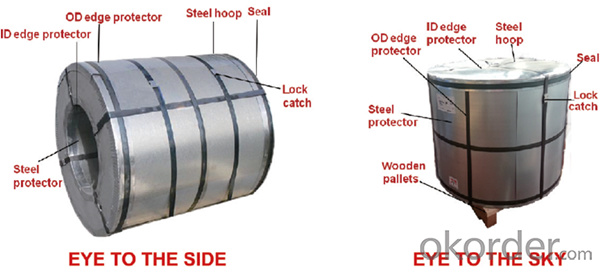

Packing:

Packaging Detail | The packing of coil consists of anti-damp paper ,PVC film ,hardboard paper , steel box , strapped with steel strips, fitted with locks and edge protectors and guarantees the optimal condition of the delivered goods. Each coil can be additionally fitted with wooden/steel skids(eye of the side) or wooden pallets(eye of the sky) |

Delivery Time | within 30 days of receipt of LC original or prepayment |

FAQ:

1. Can you offer OEM to me? What about MOQ?

Of course, we are a professional with OEM manufacturer for 9 years. the MOQ can be 50 ton/ order..

2. How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-25 days, but the shipment will depend on the vessel situation.

4.How Can I Get Some Sample?

We are honored to offer you free sample, but courier charges will be on your side.

- Q: Brass as a rule I believe is betterhowever I do not plan to get into reloading any time soon I just want some cheap practice ammo so will steel case ammo hurt my gun (semi auto) any more than brass ammo and if so how much more?

- Depends what your gun is. I wouldn't shoot steel through a 5,000 dollar gun but my SKS jams up with anything except steel ammo. It adds wear to some guns but in most cases you won't shoot enough to cause any real problems. They also make steel that is coated in lacquer that protects your gun a little. In most cases steel is no big deal, in high performance weapons I would say no.

- Q: what exactly does it mean when some sword makers refer to finding the truth of steel. I have heard that many have tried to find the truth but i dont really understand what there is to find.

- I am unsure of what the Truth of Steel is, but here is the Riddle of Steel (from Conan) Thulsa Doom: Yes! You know what it is, don't you boy? Shall I tell you? It's the least I can do. Steel isn't strong, boy, flesh is stronger! Look around you. There, on the rocks; a beautiful girl. Come to me, my child... Thulsa Doom: [coaxes the girl to jump to her death] Thulsa Doom: That is strength, boy! That is power! What is steel compared to the hand that wields it? Look at the strength in your body, the desire in your heart, I gave you this! Such a waste. Contemplate this on the tree of woe. Crucify him!

- Q: What are the different types of welding used for steel coils?

- There are several different types of welding used for steel coils, depending on the specific requirements and applications. Here are some of the most common types of welding techniques used for steel coil fabrication: 1. Shielded Metal Arc Welding (SMAW): Also known as stick welding, it involves the use of a flux-coated electrode and an electric current to create an arc between the electrode and the base material. SMAW is a versatile and widely used welding technique suitable for various steel coil applications. 2. Gas Metal Arc Welding (GMAW): Commonly known as MIG (Metal Inert Gas) welding, GMAW uses a continuous wire electrode and a shielding gas to protect the weld pool from atmospheric contamination. GMAW is known for its high welding speed and ease of automation, making it a popular choice for steel coil manufacturing. 3. Flux-Cored Arc Welding (FCAW): Similar to GMAW, FCAW uses a tubular electrode with flux inside. The flux provides both the shielding gas and additional alloying elements, resulting in increased efficiency and improved weld quality. FCAW is often used in high-speed welding applications for steel coils. 4. Gas Tungsten Arc Welding (GTAW): Also known as TIG (Tungsten Inert Gas) welding, GTAW uses a non-consumable tungsten electrode and an inert gas, typically argon, to shield the weld area. GTAW produces high-quality, precise welds with excellent control over the heat input, making it suitable for thin steel coil materials and critical welding applications. 5. Submerged Arc Welding (SAW): This welding technique involves the use of a continuously fed wire electrode and a granular flux that covers the weld area. The arc is submerged under the flux, providing excellent protection and reducing the need for post-weld cleaning. SAW is commonly used for welding thick steel coils due to its high deposition rates and deep penetration capabilities. These are just a few examples of the different types of welding techniques used for steel coil fabrication. The choice of welding method depends on factors such as the specific steel grade, thickness, desired weld quality, production speed, and cost considerations. It is essential to select the appropriate welding technique to ensure the durability and performance of the steel coils in various applications.

- Q: Are steel pokemon weak against any attacks? If so, what types? (like water, grass, etc.)

- Fire, Ground, and Fighting. 2 of the most common moves in the game now (Close Combat and Earthquake) will completely bone steel types.

- Q: What are the pros and cons to selecting a graphite shaft sand wedge over steel shaft?

- I would assume that you want to carry at least two sand wedges in your bag - the modern set makeup today will have a 52 or 54 and a 58 or 60. Unless you are getting the matching wedges to a set of graphite irons , I would go with a steel shaft in sand wedges.

- Q: How are steel coils labeled and identified?

- Steel coils are typically labeled and identified using various methods such as tags, stickers, or printed markings. These labels usually contain important information including the coil's dimensions, weight, grade, manufacturer, and any specific customer requirements. Additionally, unique identification numbers or barcodes may be used for easy tracking and inventory management.

- Q: How do steel coils contribute to the aerospace manufacturing industry?

- Steel coils are an integral component of the aerospace manufacturing industry as they provide numerous benefits and contribute to the overall efficiency and quality of aircraft production. Firstly, steel coils are used in the fabrication of various structural components of an aircraft, such as wings, fuselage, and landing gear. The high strength and durability of steel make it a suitable material for these critical parts, ensuring the safety and reliability of the aircraft. Steel coils provide the necessary raw material for the precise manufacturing processes required in the aerospace industry, allowing for the creation of lightweight yet robust structures that can withstand the demanding conditions of flight. In addition to their structural applications, steel coils are also used in the production of smaller aircraft components. These include fasteners, connectors, and brackets that hold different parts of the aircraft together. Steel's exceptional mechanical properties, including resistance to fatigue and corrosion, make it a preferred choice for such components, ensuring their long-term performance and safety. Moreover, steel coils contribute to the aerospace manufacturing industry by enabling cost-effective production processes. Steel is readily available in large quantities, making it a cost-efficient material for aircraft manufacturing. The ability to produce steel coils in various sizes and thicknesses allows manufacturers to tailor their production to specific aircraft models or design requirements, reducing waste and optimizing resource allocation. Furthermore, steel coils offer inherent recyclability, which aligns with the aerospace industry's growing focus on sustainability. Recycled steel can be used to produce new coils, reducing the need for raw material extraction and minimizing environmental impact. This circularity in the use of steel coils supports the aerospace industry's efforts towards a more sustainable and environmentally friendly manufacturing process. In conclusion, steel coils play a crucial role in the aerospace manufacturing industry by providing the necessary materials for the production of aircraft structures and components. Their strength, durability, and cost-effectiveness make them a valuable resource, ensuring the safety, reliability, and efficiency of aircraft production. Steel coils also contribute to the industry's sustainability goals through their recyclability, aligning with the growing focus on environmental responsibility.

- Q: What are the different types of surface finishes for steel coils?

- There are several different types of surface finishes for steel coils, each offering its own unique properties and advantages. Some of the most common surface finishes for steel coils include: 1. Hot Rolled: This is the most basic surface finish for steel coils and is achieved by heating the steel and then rolling it to its final shape. It typically has a rough and scale-like appearance, with varying levels of surface imperfections. 2. Cold Rolled: This surface finish is achieved by further processing hot rolled steel coils through a series of cold rolling operations. Cold rolled steel has a smoother and more uniform surface compared to hot rolled steel, with improved dimensional accuracy and better surface quality. 3. Galvanized: Galvanizing is a process in which a protective layer of zinc is applied to the surface of the steel coil. This surface finish provides excellent corrosion resistance, making it ideal for outdoor applications and environments where the steel is exposed to moisture and other corrosive elements. 4. Stainless Steel: Stainless steel coils have a unique surface finish due to the presence of chromium, which forms a thin, invisible layer of oxide on the surface. This surface finish provides excellent corrosion resistance and a visually appealing appearance. 5. Electrolytically Zinc Coated: Also known as electrogalvanized, this surface finish involves the application of a thin layer of zinc to the steel coil through an electroplating process. It provides good corrosion resistance and is commonly used in applications where aesthetics are important. 6. Pre-painted: Pre-painted steel coils have a surface finish that is coated with a layer of paint or other protective coatings. This finish offers both corrosion resistance and aesthetic appeal, allowing for a wide range of colors and finishes to be applied. 7. Aluminized: Aluminized steel coils have a surface finish that is coated with a layer of aluminum-silicon alloy. This finish provides excellent heat resistance and is commonly used in applications where high temperatures are encountered, such as exhaust systems or ovens. Overall, the choice of surface finish for steel coils depends on the specific requirements of the application, including factors such as corrosion resistance, aesthetics, durability, and heat resistance.

- Q: Can steel coils be custom-made to specific requirements?

- Yes, steel coils can be custom-made to specific requirements. Steel manufacturers have the capabilities to produce steel coils with various dimensions, thicknesses, and specifications to meet the specific needs of customers. These coils can be customized in terms of width, length, weight, and even surface finish to suit specific applications and industries. Customization can also include variations in steel grade, coating type, and mechanical properties to ensure the desired performance and functionality. The ability to tailor steel coils to specific requirements allows for optimal utilization in various sectors such as automotive, construction, appliances, and manufacturing, among others.

- Q: I was wondering whether anyone knew if painted steels rusts at the same speed as steel that isn't painted. Also, does steel rust quicker than aluminium?Thank you

- If the steel is properly prepped when painted, then it would last a long time before any rust or corrosion sets in. This still all depends if the item is subjected to water or salt and if the item you painted is not scratched in any way, once exposed from the paint, the rust will begin rapidly. As far as aluminum, no it will not rust, but you do get aluminum oxidation. It gets a white flakey appearance when it begins to oxidize. Now if you are thinking of painting the rims on a car, i recommend scuffing the rim, priming it, lightly sanding and then paint to the color of choice and for the final touch apply a clear coat on the rims to help avoid the rusting. Use a paint such as rustoleum to prolong the effects of rust settling in. good luck..... good luck.....

Send your message to us

Cold rolled carbon steel steel strip coils allibaba com

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 61450 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords