Aluminum Cold Rolled Coils and Sheets for Manufacturing Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Specification

Grade:

5000 Series

Surface Treatment:

Coated

Shape:

Rectangular

Temper:

Half Hard

Application:

Glass Wall

Gutter roof aluminium composite panel 1100 3003 pe pvdf price manufacture pre painted aluminum coil

Colored aluminum foil Brief Introduction:

| Aluminum Alloy: | AA1100,1050,1060,3003,3004,3005,3103,3105,5005,5052,5083,5754,6061,8011,O,O-H112,ETC. |

| Temper: | O,H16,H18,H22,H24,H26,H28 |

| Aluminum Alloy Thickness: | 0.08mm~1.2mm(0.08,0.18,0.28,0.38,0.48,0.6,0.8,1 mm) |

| (0.1,0.15,0.25,0.35,0.45 mm) | |

| Coil Width: | 30~1520mm hot sale price coated aluminium |

| Core Diameter: | 150/405/505mm |

| Coil Weight: | 1~2.5tons each coil for colorful marble coated aluminum coil |

| Coating Type: | PE,PVDF,back coatting,ACRYLIC,feve |

| Surface Type: | Smooth,Embossed,mill finish,coated,brushed,etc.

|

| Glossness: | 10-90%(EN ISO-2813:1994) |

| Coating Thickness: | PE:more than 18 +-1micron |

| PVDF:more than 25+-1micron | |

| Back Coating:8~10+-1micron | |

| Coating Color: | Color A:pure white, ivory, white matte,yellow white,opal,light gray, aluminum natural color etc. |

| Color B:blue,yellow,gray,black,dark gray etc. | |

| Color C:white silver gray,flash silver,champagne etc. | |

| Color D:violet,pure orange,orange,bright red,china red,dark blue,brown,green,laker blue,flash gold yellow etc. | |

| Paint Hardness: | More than 2H |

| Coating Adhesion: | 5J(EN ISO-2409:1994) |

| Impact Resistance: | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

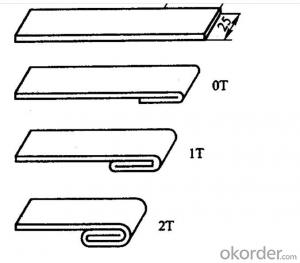

| Flexibility(T-bend): | <2T |

| MEK resistance: | More than 100 |

| Salt Fog Resistance(H): | ≥500 |

| Advantage: | 1.High temperature resistant colorful marble coated aluminum coil |

| 2.Weathering resistant | |

| 3.Scrubbing resistant | |

| 4.Sound insulation | |

| 5.Acid or alkali proof,Fireproof | |

| 6.Light weight material is easy to construct and install | |

| Packing Details: | Five-layer carton,strong polar fumigation wooden pallet,steel belt fastened outside,worthy shipping by sea. |

| Coating Aluminum Standard: | Chemical Composite:GB/T 3190-2008,JIS,EN,ASTM,Mechanical Property: GB/T 3880-2006, JIS, EN, ASTM |

| Certification: | ROHS,SGS,FDA,ISO9001:2008,GB/T 28001-2001,FORM A/E/F or CO,Mill Test Report |

| Application: | acp,aluminum composite panel,roof,gutter,ceiling,facade,wall cladding,gutter,aluminum honeycomb panel,roller shutter,rolling shutter,truck body,rolling shutter door,etc. |

Our Services

Payment: by 30%T/T in advance and balance before shipment or 100% L/C at sight

Delivery: within 30 days after we get your deposit or L/C.

Packing: sea worthy wooden pallet

Loading port: Qingdao/Shanghai/Tianjin, China

- Q: This question asks for various applications of recycled aluminum other than its traditional uses.

- <p>Recycled aluminum has a wide range of alternative uses. It can be used in the manufacturing of new aluminum products, reducing the need for raw materials. It's also used in construction for window frames, doors, and roofing. In the automotive industry, recycled aluminum is used for car parts, helping to reduce vehicle weight and improve fuel efficiency. Additionally, it's utilized in the aerospace industry for lightweight aircraft components. Recycled aluminum is also found in everyday items like cans, foil, and packaging materials. Furthermore, it's used in electrical components due to its excellent conductivity, and in the production of bicycles and sports equipment for its strength and lightweight properties.</p>

- Q: This question asks about the methods used to determine the hardness of aluminum material.

- <p>The hardness of aluminum can be measured using various standardized tests. The most common methods include the Brinell Hardness Test, where a hard steel or carbide ball is pressed into the aluminum surface, and the Vickers Hardness Test, which uses a diamond pyramid indenter. The Rockwell Hardness Test is also used, applying a diamond cone or steel ball to the surface. The hardness is quantified by the depth of the indentation, and the results are expressed in specific hardness units like BHN (Brinell Hardness Number), HV (Vickers Hardness), or HR (Rockwell Hardness). These tests provide a measure of the material's resistance to deformation, which is crucial for applications requiring strength and durability.</p>

- Q: This question asks about the impact of weathering on aluminum surfaces, including potential changes and effects.

- <p>The weathering process can significantly affect aluminum surfaces. Aluminum naturally forms a protective oxide layer when exposed to air, which provides corrosion resistance. However, over time, weathering can lead to the thinning or damage of this oxide layer, especially in harsh environments. This can result in corrosion, pitting, or discoloration. Additionally, weathering can cause physical changes such as surface roughening due to the differential erosion of the aluminum and its protective layer. In coastal areas, the presence of salt can accelerate these effects. Proper maintenance, such as regular cleaning and protective coatings, can help mitigate the effects of weathering on aluminum surfaces.</p>

- Q: Explain the natural relationship between aluminum and magnesium, focusing on their abundance and reactivity in the Earth's crust.

- <p>Aluminum and magnesium are both abundant elements in the Earth's crust, with aluminum being the most abundant metal and magnesium being the eighth most abundant element overall. They are often found in close association within the same minerals, such as in aluminosilicates and some carbonates. Both elements are highly reactive, forming compounds readily with oxygen to create oxides and silicates. However, they differ in their reactivity with water; aluminum forms a protective oxide layer that prevents further reaction, while magnesium reacts more readily with water to form magnesium hydroxide. This difference in reactivity influences their distribution and the types of compounds they form in nature.</p>

- Q: Explain how the incorporation of titanium into aluminum alloys influences their properties and strength.

- <p>Adding titanium to aluminum alloys significantly enhances their mechanical properties and strength. Titanium increases the alloy's strength, hardness, and resistance to corrosion. It also improves the alloy's creep resistance, which is crucial for high-temperature applications. The addition of titanium refines the grain structure, leading to better ductility and toughness. Moreover, titanium helps to reduce the likelihood of stress-corrosion cracking, making the alloy more reliable in aggressive environments. Overall, titanium-aluminum alloys are stronger, more durable, and have a wider range of applications than pure aluminum or simple aluminum alloys.</p>

- Q: This question asks about the potential health and safety risks associated with exposure to aluminum.

- <p>Aluminum exposure can lead to several safety issues. Chronic exposure may lead to neurological problems, including cognitive dysfunction and Alzheimer's disease, though the link is still debated. It can also cause bone diseases by leaching calcium from bones. Aluminum may contribute to kidney dysfunction and anemia. In occupational settings, inhalation of aluminum dust can lead to respiratory issues. It's important to note that the human body naturally eliminates aluminum, and the risk of toxicity is generally low under normal conditions. However, in certain medical conditions or with high exposure, aluminum can accumulate and pose health risks.</p>

- Q: This question asks for a brief explanation of the process of recycling aluminum.

- <p>Aluminum recycling involves several steps. First, aluminum waste is collected and sorted. It is then cleaned to remove any contaminants. The cleaned aluminum is melted in a furnace at high temperatures, which is an energy-efficient process as aluminum has a lower melting point compared to other metals. The molten aluminum is then poured into molds to form new products. This process is highly sustainable as it saves energy and reduces waste, with recycled aluminum requiring only 5% of the energy needed to produce new aluminum from raw materials. Recycled aluminum maintains its quality, making it an ideal material for continuous recycling.</p>

- Q: This question asks about the process of producing aluminum, a common metal known for its lightweight and corrosion resistance.

- <p>Aluminum is made through a process called electrolysis. The primary source of aluminum is bauxite ore, which is first refined to produce aluminum oxide. This aluminum oxide is then dissolved in a molten cryolite bath and subjected to electrolysis. A large electric current is passed through the bath, causing the aluminum oxide to break down into aluminum metal and oxygen gas. The aluminum metal sinks to the bottom of the cell and is then tapped off and further processed. This process, known as the Hall-H茅roult process, is the predominant method for producing aluminum on an industrial scale.</p>

- Q: This question asks for an explanation of the process involved in the production of aluminum foil.

- <p>Aluminum foil is made through a process that starts with the extraction of aluminum from its ore, bauxite. The bauxite is refined to produce aluminum oxide, which is then reduced to aluminum using the Hall-H茅roult process. The aluminum is then melted and cast into large ingots. These ingots are heated and rolled into thin sheets using large industrial rolling mills. The aluminum is rolled multiple times, each pass reducing its thickness until it reaches the desired foil thickness. The final thin sheets are then cut and packaged as aluminum foil. This process requires precision and control to ensure the foil is uniform and free of defects.</p>

- Q: Explain how aluminum influences the synthesis and function of neurotransmitters.

- <p>Aluminum has been suggested to affect the production of neurotransmitters by potentially disrupting the normal functioning of enzymes and receptors involved in neurotransmitter synthesis and release. It may interfere with the uptake of essential metals like magnesium and zinc, which are crucial for the proper functioning of neurotransmitter systems. Aluminum can also alter the permeability of cell membranes, affecting the transport of neurotransmitters across the synaptic cleft. Additionally, there is evidence that aluminum may contribute to oxidative stress, which can impair the synthesis and function of neurotransmitters. However, it's important to note that the exact mechanisms are not fully understood, and more research is needed to establish a definitive link between aluminum exposure and neurotransmitter dysfunction.</p>

Send your message to us

Aluminum Cold Rolled Coils and Sheets for Manufacturing Curtain Wall

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords