Aluminum Coil Goodman 0270a00983 - Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3A21 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum or paper |

7) Coil Inner diameter | 75mm, 150mm, 200mm, 300mm, 405mm, 505mm or as required |

8) Protective film can be added

2. Application of Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

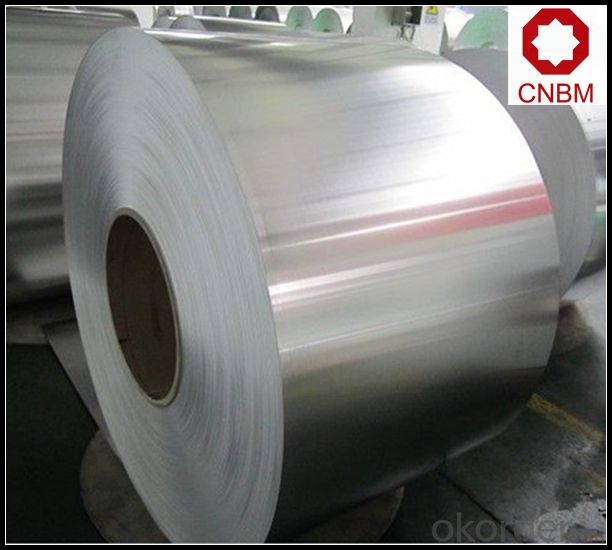

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

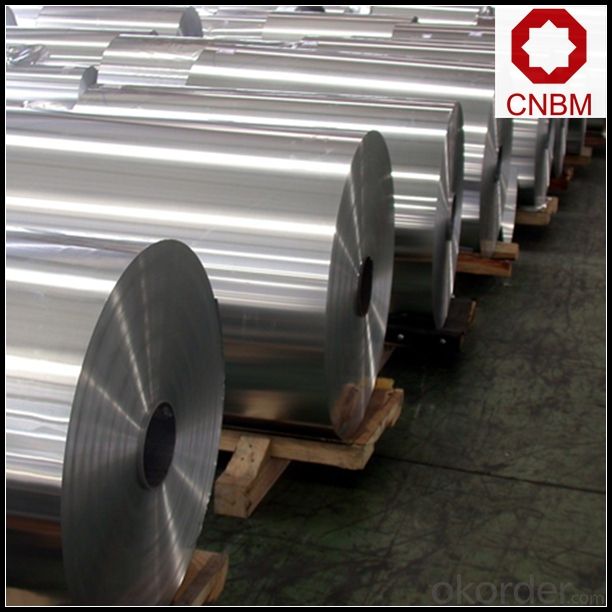

5. Image of Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

6. Package and shipping of Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What specific conditions or precautions need to be taken into account when storing and transporting steel wires intended for coiling purposes?

- <p>Yes, there are special requirements for storing and transporting steel wires for coiling. These wires must be kept dry to prevent rust and should be stored in a cool, dry place away from direct sunlight or extreme temperatures. They should be handled carefully to avoid kinks or deformations. When transporting, it's important to secure the coils to prevent shifting during transit, which could cause damage. Additionally, the packaging should be robust enough to protect the wires from moisture and physical damage.</p>

- Q: How are aluminum coils protected against oxidation during storage?

- Aluminum coils are protected against oxidation during storage by applying a thin layer of protective coating or by storing them in a controlled environment, such as a dry and moisture-free area. This prevents exposure to oxygen and moisture, which are the main factors contributing to oxidation.

- Q: Is it possible to use a crowbar as a tool for opening an aluminum coil?

- <p>While a crowbar can be used to apply force to open various objects, it may not be the most suitable tool for opening an aluminum coil. Aluminum coils can be sharp and using a crowbar could lead to injury or damage to the coil. It's recommended to use gloves and a pair of pliers or a coil cutter specifically designed for handling aluminum coils to ensure safety and avoid damaging the material.</p>

- Q: Can aluminum coils be used in the production of solar reflectors?

- Certainly! Solar reflectors can utilize aluminum coils in their production. Due to its exceptional reflectivity and durability, aluminum is widely employed in the manufacturing of these reflectors. The coils can be manipulated and molded into the desired shape for the reflector, facilitating efficient sunlight reflection onto the solar panels. Furthermore, aluminum's lightweight nature simplifies its handling and installation in solar reflector systems.

- Q: How are aluminum coils protected against damage during handling?

- Aluminum coils are protected against damage during handling through various methods and precautions. Firstly, they are usually wrapped in a protective layer, such as plastic or paper, to provide a barrier against any physical contact or scratches. This protective wrapping also helps prevent moisture or dirt from coming into direct contact with the coils. Additionally, aluminum coils are often secured onto pallets or placed inside crates for added protection during transportation. These pallets or crates act as a buffer, absorbing any shocks or impacts that may occur during handling or shipping. This reduces the risk of dents, bends, or other forms of damage that could compromise the integrity of the coils. Furthermore, proper handling techniques are employed to ensure the coils are not mishandled or dropped. Forklifts or cranes are commonly used to lift and move the coils, minimizing the risk of human error or accidental damage caused by manual handling. Overall, a combination of protective wrapping, secure packaging, and careful handling practices are implemented to safeguard aluminum coils against potential damage during their transportation and handling processes.

- Q: Can aluminum coils be used in the production of beverage cans?

- Certainly, beverage cans can indeed be produced using aluminum coils. Aluminum is the preferred material for manufacturing beverage cans due to its lightweight nature, durability, and ability to maintain the taste and quality of the contents. Typically, aluminum coils are employed in the canning process as they can be readily molded into the desired can shape. These coils are rolled into sheets, which are subsequently cut and transformed into cans. Additionally, aluminum coils possess exceptional heat conductivity, enabling efficient cooling and faster production rates. All in all, aluminum coils play a crucial role in the production of beverage cans and are extensively utilized within the industry.

- Q: How are aluminum coils tested for surface adhesion?

- Aluminum coils are tested for surface adhesion through various methods such as tape tests, peel tests, and wet adhesion tests. These tests involve applying adhesive tapes, peeling them off, and evaluating the level of coating adhesion. Additionally, wet adhesion tests involve subjecting the coils to water or chemical exposure to assess the durability of the coating. These procedures help determine the quality and adherence of the surface coating on aluminum coils.

- Q: What are the common sizes of aluminum coils available?

- The common sizes of aluminum coils available vary depending on the specific application and industry. However, some standard sizes include widths ranging from 36 inches (91 cm) to 72 inches (183 cm) and thicknesses between 0.019 inches (0.048 cm) to 0.125 inches (0.318 cm). These sizes are commonly used in industries such as construction, automotive, and manufacturing.

- Q: This question seeks advice on methods to prevent rust formation on aluminum coils.

- <p>To prevent rust on aluminum coil, ensure proper storage conditions by keeping the coils dry and avoiding contact with moisture. Use protective coatings or sealants that are compatible with aluminum to create a barrier against the elements. Regularly inspect the coils for signs of corrosion and clean them with a non-abrasive cleaner to remove any contaminants. Avoid using harsh chemicals that could accelerate oxidation. Maintain good ventilation in storage areas to reduce humidity, which can contribute to rust formation. Finally, consider using anodizing or other surface treatments that enhance the aluminum's natural resistance to corrosion.</p>

- Q: I know this question is not so bright, but I am very curious why do we recycle aluminum cans? Is it that they are not biodegradable?

- Heck yeah. Even an old school, smoke-belching industrialist would recycle *metal*. That's always been true. Why did people suddenly stop recycling metals? Have you PRICED metals lately? Aluminum is over a buck a pound, copper is $3 a pound, steel is over $200 a ton.

Send your message to us

Aluminum Coil Goodman 0270a00983 - Cold Rolled Aluminium Coil in Roll 1.5 mm 3104 3003

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords