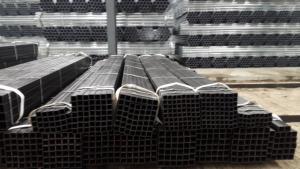

Cold formed welded square rectangular pipe for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1、 Square rectangular tubes for buildings

Square tube, square tube is a kind of call and rectangular tube, is equal and not equal to the length of steel pipe. Is the strip through the process of processing roll system. In general is the strip through the demolition of the package, flat, curly, welded to form a circular tube, and then rolled into a square tube and then cut into a square tube and then cut into the required length.

2、 Square rectangular tubes for buildings

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、 Square rectangular tubes for buildings

Standard | GB, DIN, ASTM |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 1.5 - 25 mm |

Section Shape | Square and rectangular |

Outer Diameter | 20*20 mm-------400*400mm 20*30mm*300*500mm |

Place of Origin | Tianjin, China (Mainland) |

Length | 3-12M |

Outer Diameter | 20*20 mm-------400*400mm 20*30mm*300*500mm |

Grade | 235B 345B |

Standard | ASME, ASTM |

1) Material:(ASTM A 106/A53 GRB.API5LGRB,GB,235B,345B

2) Specification range:OD: 20*30mm----300*500mm 20*20 mm---400*400mm ,WT: 1.5 - 25 mm ,length:3-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut ,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、 Square rectangular tubes for buildings

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

6、 Square rectangular tubes for buildings

- Q: What is the difference between carbon steel and stainless steel pipes?

- The main difference between carbon steel and stainless steel pipes lies in their composition and rust resistance properties. Carbon steel pipes are primarily made of iron and carbon, making them less resistant to corrosion and prone to rusting. On the other hand, stainless steel pipes contain chromium, which gives them excellent rust resistance and durability. This makes stainless steel pipes ideal for use in environments where corrosion is a concern, such as in plumbing systems and industrial applications.

- Q: What are the different types of steel pipe connections for oil and gas pipelines?

- The different types of steel pipe connections for oil and gas pipelines include threaded connections, welded connections, and flanged connections. Threaded connections involve screwing the pipes together using a threaded end, which ensures a secure fit. Welded connections involve permanently joining the pipes together using welding techniques such as butt welding or socket welding. Flanged connections involve attaching flanges to the ends of the pipes and bolting them together, providing a strong and leak-proof connection.

- Q: Is the PVC tube a plastic tube or a plastic tube?.

- It's plastic tubePolyvinyl chloride (Poly, Vinyl, Chloride, PVC)PVC is a VCM monomer (vinyl, chloride, monomer), in peroxide, azo compounds and other initiators;

- Q: What is the pressure rating of steel pipes?

- The pressure rating of steel pipes varies depending on the specific grade and size of the pipe. However, steel pipes are known for their high strength and durability, allowing them to withstand high-pressure applications.

- Q: Can steel pipes be used for oil refinery applications?

- Yes, steel pipes can be used for oil refinery applications. Steel pipes offer many advantages for oil refinery applications including high strength, durability, and resistance to corrosion. They are able to withstand high pressure and temperature conditions that are common in oil refinery operations. Steel pipes are also easy to transport and install, making them a popular choice for oil refinery projects. Additionally, steel pipes can be customized to meet specific requirements such as size, thickness, and coating, making them suitable for a wide range of oil refinery applications.

- Q: How are steel pipes used in the construction of railways and transportation systems?

- Various purposes necessitate the common use of steel pipes in the construction of railways and transportation systems. Bridges and tunnels, in particular, heavily rely on steel pipes. In bridge construction, steel pipes act as structural components, providing overall support and stability. As for tunnels, steel pipes serve as ventilation shafts, promoting air circulation and the removal of fumes, thus ensuring the safety of passengers and workers. Furthermore, steel pipes find utility in the construction of railway tracks. They are utilized as supports, offering a stable foundation for train travel. In this context, steel pipes are typically coated or galvanized to prevent corrosion and guarantee their longevity. Additionally, steel pipes are employed in drainage systems within railway stations and transport hubs, playing a crucial role in proper water management and the prevention of flooding. Another significant application of steel pipes in transportation systems lies in the construction of signposts and streetlights. In these structures, steel pipes often serve as the primary structural element, providing strength and durability. Their malleability and ease of fabrication make them a sought-after choice, as they can be shaped to meet specific design requirements. In summary, steel pipes assume a vital role in the construction of railways and transportation systems, offering structural support, ensuring adequate ventilation, facilitating drainage, and serving as key components in various structures. Their strength, durability, and versatility render them an ideal choice for these applications, contributing to the safe and efficient operation of transportation networks.

- Q: How are steel pipes used in the agriculture industry?

- Steel pipes are used in the agriculture industry for various purposes such as irrigation systems, drainage systems, and livestock handling equipment. They provide a durable and reliable solution for transporting water, nutrients, and effluents, ensuring efficient and effective operations in farm settings.

- Q: Can steel pipes be used for drinking water supply?

- Yes, steel pipes can be used for drinking water supply. However, it is important to ensure that the pipes are properly coated or lined to prevent corrosion and any potential contamination of the water. Regular maintenance and monitoring are also necessary to ensure the pipes remain in good condition for safe drinking water supply.

- Q: How do steel pipes perform in earthquake-prone regions?

- Steel pipes perform well in earthquake-prone regions due to their high strength and ductility. They are capable of flexing and absorbing seismic energy, reducing the risk of catastrophic failure. Additionally, steel pipes can be designed with proper reinforcement to withstand ground movements, making them a reliable choice for infrastructure in earthquake-prone areas.

- Q: What is the difference between black steel pipe and galvanized steel pipe?

- The main difference between black steel pipe and galvanized steel pipe lies in their coating. Black steel pipe is untreated and has a dark, matte appearance, while galvanized steel pipe is coated with a layer of zinc to prevent rusting and has a silver, shiny appearance. This coating makes galvanized steel pipes more durable and suitable for outdoor use, while black steel pipes are commonly used for indoor plumbing and gas lines.

Send your message to us

Cold formed welded square rectangular pipe for construction

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 15000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords