Coated Steel Composite Pipe for Water Supply

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Coated Steel Composite Pipe for Water Supply

Press grade: Applied for pipe system not bigger than 10MPa

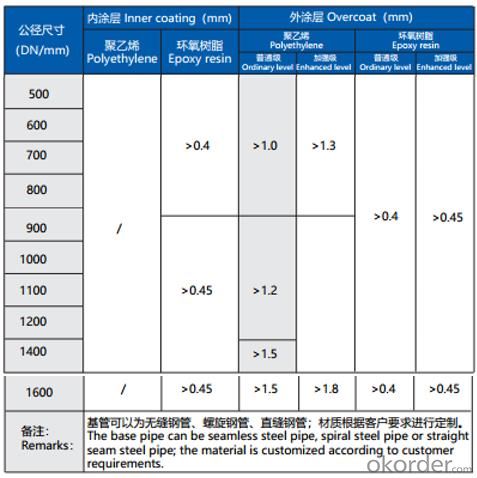

Size: DN50MM-DN1600MM

Specification

Features:

- Q: How are steel pipes used in the construction of wastewater treatment plants?

- Steel pipes are commonly used in the construction of wastewater treatment plants due to their durability, strength, and corrosion resistance. These pipes are used to transport wastewater from different points within the treatment plant, such as pipes for raw sewage, sludge, and treated water. Additionally, steel pipes are also used for structural purposes, such as supporting tanks and other equipment. Overall, steel pipes play a crucial role in the efficient and reliable operation of wastewater treatment plants.

- Q: What are the different methods of pipe threading for steel pipes?

- The different methods of pipe threading for steel pipes include manual threading, machine threading, and electric threading. Manual threading involves using a handheld die or tap to create the threads on the pipe. Machine threading utilizes power-driven machines that can thread multiple pipes simultaneously, offering efficiency and accuracy. Electric threading is similar to machine threading, but it uses an electric motor to drive the threading process.

- Q: How are steel pipes used in data centers?

- Steel pipes are commonly used in data centers for various purposes such as routing cables, running water cooling systems, and providing structural support for equipment. They are used to create a robust and organized network infrastructure, ensuring efficient and reliable data transmission and management within the facility.

- Q: How are steel pipes used in offshore drilling platforms?

- Steel pipes are used in offshore drilling platforms for various purposes such as transporting drilling fluids, casing and cementing operations, as well as providing support and stability to the platform structure. These pipes are crucial in facilitating the extraction of oil and gas from beneath the seabed by enabling the safe and efficient transfer of fluids and materials during drilling operations.

- Q: What are the applications of steel pipes in the automotive industry?

- Steel pipes are widely used in the automotive industry for various applications such as exhaust systems, fuel lines, and structural components. These pipes provide durability, high strength, and resistance to corrosion, making them ideal for withstanding the harsh conditions and requirements of automotive applications. Additionally, steel pipes are lightweight, cost-effective, and offer excellent formability, enabling efficient manufacturing and design flexibility for automotive manufacturers.

- Q: What are the different types of steel pipe unions?

- Various industries and applications commonly utilize several types of steel pipe unions. Some of the most frequently used types are as follows: 1. Threaded Union: This union features female threads on both ends, facilitating easy attachment to two male threaded pipes. It ensures a reliable connection that is resistant to leaks. 2. Socket Weld Union: On one end, this union has a socket, while the other end is equipped with a female threaded connection. It is specifically designed for socket welding, where the pipe is inserted into the socket and then welded around the joint, resulting in a robust and long-lasting connection. 3. Butt Weld Union: This specific union is employed for joining two pipes with butt weld ends. It necessitates beveling the pipes and subsequently welding them together, creating a sturdy and permanent connection. 4. Compression Union: Typically used for connecting pipes made of softer materials like copper or plastic, compression unions consist of a compression nut and a compression ring. These components are tightened onto the pipe, ensuring a tight and secure seal. 5. Flanged Union: This union is equipped with flanges on both ends, allowing it to be bolted onto two flanged pipes. Flanged unions are commonly utilized in applications where easy disassembly and reassembly are necessary. 6. Grooved Union: Grooved unions possess grooves on their ends, which are utilized for connecting pipes by inserting them into the grooves and securing them with a coupling. They are often utilized in fire protection systems and other applications where quick installation and easy maintenance are of utmost importance. These examples represent only a fraction of the numerous types of steel pipe unions available. The selection of a union depends on the specific requirements of the application, such as the pipe material, size, and operating conditions. Seeking advice from a professional or consulting industry standards can aid in determining the most suitable union for a particular project.

- Q: Water, gas, steel pipes, thick steel wire means?

- Water pipes, gas pipes and other collectively known as water gas pipe, generally galvanized steel pipe, so it can be called water and gas pipe. Most of them are welded steel tubes made of low carbon steel.

- Q: What is the role of steel pipes in the transportation of chemicals?

- The role of steel pipes in the transportation of chemicals is to provide a safe and reliable means of transporting various types of chemicals over long distances. Steel pipes are highly resistant to corrosion, which is crucial when dealing with corrosive chemicals. They are also strong and durable, ensuring that the pipes can withstand the pressure and weight of the chemicals being transported. Additionally, steel pipes are able to maintain the integrity of the chemicals, preventing any leakage or contamination during transportation. Overall, steel pipes play a vital role in ensuring the efficient and secure transportation of chemicals.

- Q: How are steel pipes insulated to prevent heat loss?

- Steel pipes are typically insulated to prevent heat loss by wrapping them with insulation materials such as mineral wool, fiberglass, or foam. These insulation materials provide a barrier that traps heat within the pipes, preventing it from being lost to the surrounding environment. Additionally, pipes may also be covered with an outer protective layer, such as aluminum or PVC, to further enhance insulation and protect against external elements.

- Q: What is the impact resistance of steel pipes?

- The impact resistance of steel pipes is quite high due to the inherent properties of steel as a material. Steel is known for its strength and durability, which makes it able to withstand significant external forces and impacts without deforming or breaking. The impact resistance of steel pipes is further enhanced by their construction and design. Steel pipes are typically made using various manufacturing techniques such as seamless or welded construction, which ensures uniformity and strength throughout the pipe structure. This construction process eliminates weak points or seams that could compromise the impact resistance of the pipe. Moreover, steel pipes can be engineered to meet specific requirements for impact resistance based on the intended application. Different grades and types of steel can be used to achieve varying levels of impact resistance, allowing for customization to suit different industries and environments. The high impact resistance of steel pipes is particularly advantageous in industries such as construction, oil and gas, and transportation, where pipes are subjected to heavy loads, pressure, and potential impacts. Steel pipes can withstand these conditions, making them a reliable choice for various applications. In summary, the impact resistance of steel pipes is excellent due to the inherent strength and durability of steel as a material, as well as the construction techniques used in their manufacturing. Steel pipes can withstand significant external forces and impacts, making them a reliable and robust choice for a wide range of industries and applications.

Send your message to us

Coated Steel Composite Pipe for Water Supply

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords