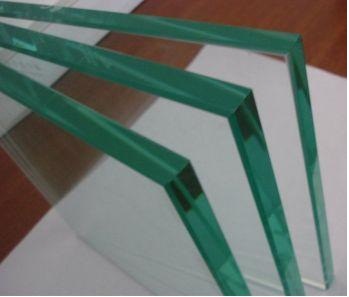

Toughened glass Security features Thermal stability High strength

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000㎡ m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

Provide QAIC/CN attestationProvide ISO 9001-2008 CCC attestation

Provide super quality and competitive price

Tempered, toughened glass is heated to the temperature that near soft point, the surface resulting from the rapid cooling homogeneity has powerful compressive stress, the glass is double increase in all mechanical performance indexes. The surface stress value for tempered glass is more than 90Mpa and 24-69Mpa for the semi-tempered or toughened glass.

The feature of tempered glass:

High intensity: The bending strength of tempered glass is 3-4 times than common glass and the shock strength is 6-7 times than common glass.

Heat stability: Tempered glass has good thermal stability can withstand a range in 300 ℃temperatures, which is 3 times than common glass.

Security: Because of the stress layer of tempered glass, thus has strong shock resistance, make its not easy to damage, and it will not cause greater harm to human body when the broken glass after obtuse angle formed by small particles.

Toughened glass is also called heat enhancement or tempered glass, its strength is 1.5 to 2 times of ordinary annealed glass, thermal stability is twice as common annealed glass, toughened glass of flatness is approach to ordinary annealed glass and far superior to toughened glass, its biggest advantage is that there is no explosive's ills, but once causing damage, it still produces larger pieces and after its damage easily hurt the body, but its security is better than ordinary annealed glass.

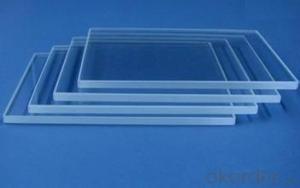

Maximum processing size: 11000 mm * 3000 mm

Minimum processing size: 200 mm * 300 mm

The range of glass thickness: 4 mm to 25 mm

Insulating Glazing

A. All glass can be processed before assembly

B. Glass transfer onto the glass loading machine

C. Edge coating removing of coated glass

D. Wash and clean strictly

E. Automatic bending for air spacer

F. Automatic molecular sieve filling

G. Automatic butyl rubber applying

H. Automatic framing

K. Automatic scanning positioning

L. Automatic double sealing

M. Transfer by sucking disc

N. Conner finishing

O. Glass on the shelves till solidification

P. Customized wooden cases according to the size of glass

Q. Transfer the glass into the specific wooden cases

R. Leading Time:10 days for an average area of 1000 square

meters tempered glass

S. Trade terms: FOB and CIF.

T. Payment Terms: By TT, 30% deposit to start producing,

full amount balance paid before delivery.

U. The container loading after the package checking

- Q: How to adjust the glass parameters

- R Common material parameters White wall: white -245 reflection 23 high light 0.25 to remove the reflection [let him only high light without reflection]

- Q: Which parts of the building must use safety glass

- Vulnerable to impact, the impact of other parts of the body caused by injury.

- Q: Lanzhou Huazhong hollow glass factory where

- I was in Chengdu, Sichuan State-level economic and technological development zone of glass deep processing enterprises, in our park also Huacao building materials, and its enterprises mainly engaged in the production of steel profiles and sales, but also set up a steel doors and windows factory, including products, there are insulating glass Building glass supporting sales.

- Q: The Louvre pyramid in Paris, France, is built of glass panes. There are 4 panes in the top row, and each additional row has 4 more panes than the previous row. 1.Write a series in summation notation to describe the total number of glass panes in n rows of the pyramid. 2.If the pyramid were made of 18 complete rows, how many panes would it have? 3.The actual pyramid has 11 panes less than a complet 18-row pyramid because of the space for the entrance. Find the total number of panes in the Louvre pyramid.

- So the first row has 4 panes, the second 8, the third 12, and so on. The nth row would have 4n panes. 1. The total number of glass panes in n rows is 4*1 + 4*2 + 4*3 + ... + 4n or, in summation notation: n ∑ 4i i=1 2. n=18 4*1 + 4*2 + 4*3 + ... + 4*18 = 4 (1+2+3+ ... + 18) = 4 * 18 * 19 / 2 [using the well-known formula for triangular numbers*] = 36*19 = 684 * T(n) = n(n+1)/2 3. 684-11 = 673

- Q: Frosted glass film can not be attached to the wall

- Frosted glass film can be attached to the wall, as long as the wall is smooth and can be affixed. Matte film is broadly divided into ordinary glass matte film and touch screen matte film, is the object from the surface smooth into the surface is not smooth.

- Q: I do building glass exports, do not know how to find customers, do architectural glass, the target customers should be what? I am talking about the target customer! Trouble

- Shandong Province to do professional curtain wall doors and windows glass, indoor glass partition, safety fire glass

- Q: Why is the glass surface of the glass after the glass film?

- On the contrary, not film or paste the poor quality of the membrane temperature is always difficult to come down, because the outside of the heat continue to come in, and the car's air-conditioning constantly out. Posted a good film winter insulation is the principle.

- Q: Is the car 's annual inspection posted directly on the glass and can affix the solar film?

- You can first check the label and then paste the film so good, you go to the film where they have a way to engage in the annual inspection label down, with a new blade (note the best with the new relatively flat) close to the glass Cut can also cut off.

- Q: What is the principle of self-cleaning of self-cleaning glass? Why is it called self-cleaning glass?

- The ECOFRIEND-ING4 nanometer glass self-cleaning agent does not form a layer of coated coating on the surface of a glass or other surface, except that the protective coating is different from the conventional protective coating. The surface growth of glass is ≤ 15 nm in the invisible nanotube lattice. Therefore, the nano-lattice reduces the glass surface tension, resulting in strong hydrophobicity, contact angle up to 114 °, through the chemical bond firmly bonded to become part of the glass surface. Nano-lattice to reduce the glass surface tension, resulting in strong hydrophobicity, so that the glass like lotus-like water and water pollution, "out of the sludge and not dye", put an end to the water, stains, organic detergent and glass surface directly Contact, can not penetrate the glass inside, effectively preventing the corrosion of aging, anti-wear scratches, effectively extending the cleaning time and service life. To keep the glass as a whole clean and bright, called the German nanotechnology miracle! ECOFRIEND-ING4 Nano glass self-cleaning agent Use: architectural glass, curtain wall glass, shower room glass, car glass, sanitary ware, kitchen ceramics, all kinds of tiles and so on.

Send your message to us

Toughened glass Security features Thermal stability High strength

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000㎡ m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords