032 Aluminum Coil Black Coated Aluminum Embossed Sheets with Cheap Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Embossed Aluminum Sheets

Embossed Aluminum Sheets has great ductility, heat conductivity, anti-corrosion and moisture resistance properties which are very useful in the field of construction.

Embossed Aluminum Sheets is widely used for decorative purpose in construction, packing and appiance. It is also very commonly used for anti-slippery purpose in vehicles and public places.

2.Main Features of Embossed Aluminum Sheets

• Superior quality of raw material

• Reasonable and stable chemical composition

• Accurate tolerance

• Goode mechanical property

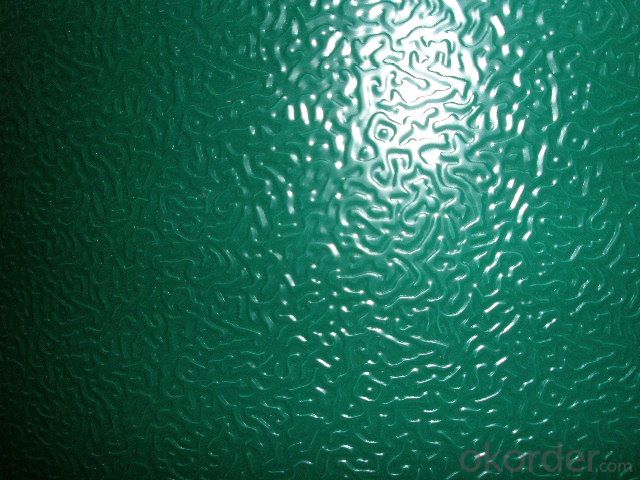

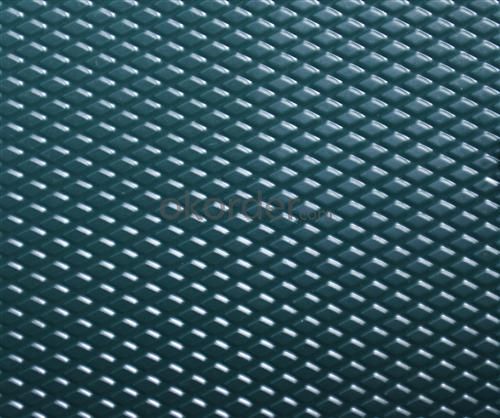

3.Embossed Aluminum Sheets Images

4.Embossed Aluminum Sheets Specification

| Alloy | AA1xxx,AA3xxx,AA5xxx |

| Temper | H14,H18,H24,H26,H32 |

| Thickness | 0.2mm--20mm |

| Width | 10mm--1500mm |

| Embossed Patterns | Diamond,Stucco,Bars etc. |

| Standard | GB/T 3880-2006 |

5. FAQ of Embossed Aluminum Sheets

A.How to guarantee the quality?

Customers are welcome to our mill to visit and check the products. Besides, we can arrange a third party to test Embossed Aluminum Sheets products.

B.When will you deliver the products?

Embossed Aluminum Sheets will be delivered within 35 days after receiving advanced payment or original L/C.

- Q: Can aluminum coils be used in the production of household appliances?

- Yes, aluminum coils can be used in the production of household appliances. Aluminum is a lightweight, durable, and corrosion-resistant material, making it suitable for various applications in appliances such as refrigerators, air conditioners, and cooktops. Additionally, aluminum coils offer excellent heat transfer properties, making them an ideal choice for enhancing energy efficiency in appliances.

- Q: i need ONE advantage of each, and a final reason why aluminium is used?

- Copper does conduct slightly better than aluminum, but aluminum corrodes over time and the oxidized surface has very high resistance. Copper also oxidizes but is not as high a resistance. The high resistance, when in contact with another conductor, like a junction inside a box, will create heat. Those high resistance junctions create so much heat that over time a fire hazard develops. Hence, National Electrical Code disallowed the use of aluminum for safety reasons.

- Q: Are aluminum coils suitable for interior decorative applications?

- Yes, aluminum coils are suitable for interior decorative applications. Aluminum is a lightweight and versatile material that can be easily shaped into various forms, making it ideal for decorative purposes. It also comes in a wide range of finishes, colors, and patterns, allowing for endless design possibilities. Additionally, aluminum is highly durable and resistant to corrosion, ensuring that it will maintain its aesthetic appeal over time. Moreover, aluminum is a sustainable material, as it can be recycled indefinitely, making it an environmentally friendly choice for interior decorations. Overall, aluminum coils provide a cost-effective and aesthetically pleasing option for interior decorative applications.

- Q: What are the different types of surface treatments for corrosion resistance?

- Various materials can benefit from different surface treatments to enhance their resistance to corrosion. These treatments can be grouped into mechanical, chemical, and electrochemical methods. 1. To improve corrosion resistance, mechanical surface treatments involve physically altering or modifying the material's surface. Shot peening, sandblasting, and polishing are common methods. Shot peening induces compressive stresses by bombarding the material with small metal pellets, preventing corrosion. Sandblasting removes existing corrosion and creates a clean, smooth surface by blasting it with abrasive particles. Polishing, using abrasives, creates a smooth, reflective surface that reduces the chances of corrosion initiation. 2. Chemical surface treatments involve applying a chemical solution or coating to create a protective layer against corrosion. Chromating, for example, applies a chromate conversion coating that acts as a barrier against corrosion and improves adhesion for subsequent paint or coating layers. Anodizing, commonly used for aluminum surfaces, creates a thick oxide layer that enhances corrosion resistance and can provide decorative finishes. Other chemical treatments, like phosphating, passivation, and galvanizing, use specific chemical solutions or coatings to protect against corrosion. 3. Electrochemical surface treatments utilize electrochemistry principles to create a protective layer. Electroplating involves depositing a thin layer of a more corrosion-resistant material, such as zinc, nickel, or chromium, onto the base material's surface. Anodic protection connects a sacrificial anode to the material, causing the anode to corrode instead of the material itself. This method is commonly used for underground structures and pipelines. The choice of surface treatment for corrosion resistance depends on factors like the material, intended application, and desired level of protection. It is crucial to consider factors like cost, environmental impact, and performance requirements when selecting the appropriate treatment, as each method has its advantages and limitations.

- Q: What is the impact of alloy purity on the performance of aluminum coils?

- The performance of aluminum coils is greatly influenced by the purity of the alloys used. Alloy purity refers to the absence of impurities or contaminants within the aluminum material. The mechanical strength of the aluminum coils is one important factor that is affected by alloy purity. Impurities in the alloy can weaken the overall structure and decrease its tensile strength. Alloys with higher purity tend to have better mechanical properties, enabling the coils to withstand higher loads and stresses without deforming or failing. Alloy purity also plays a role in the electrical conductivity of aluminum coils. Impurities like iron, copper, or silicon can increase electrical resistance, resulting in energy losses during transmission. Alloys with higher purity have lower electrical resistivity, ensuring efficient power transmission and minimizing energy loss. Corrosion resistance is another critical aspect influenced by alloy purity in aluminum coils. Impurities can act as catalysts for corrosion, reducing the coil's lifespan and durability. Alloys with higher purity exhibit improved resistance to corrosion, making them suitable for various applications, especially those in corrosive environments. Furthermore, alloy purity affects the thermal conductivity of aluminum coils. Impurities hinder the efficient transfer of heat, reducing overall thermal performance. Alloys with higher purity have better thermal conductivity, allowing for effective heat dissipation and improved thermal management in applications like heat exchangers or cooling systems. To summarize, the impact of alloy purity on the performance of aluminum coils is significant. Alloys with higher purity offer improved mechanical strength, electrical conductivity, corrosion resistance, and thermal conductivity. Therefore, selecting alloys with higher levels of purity is crucial to ensure optimal performance and longevity of aluminum coils in various applications.

- Q: Is it possible to utilize aluminum coils in the manufacturing process of solar panels?

- <p>Yes, aluminum coils can be used in the production of solar panels. Aluminum is a common material used in solar panel frames due to its lightweight, high strength, and excellent heat dissipation properties. It also offers good resistance to corrosion, which is crucial for outdoor applications. Aluminum coils are often chosen for their ease of manufacturing and cost-effectiveness, making them a suitable choice for constructing the frame or support structure of solar panels.</p>

- Q: Are aluminum coils suitable for food processing and packaging?

- Yes, aluminum coils are suitable for food processing and packaging. Aluminum is a versatile metal that offers numerous benefits for the food industry. Firstly, aluminum has excellent thermal conductivity, which allows for efficient heat transfer during food processing and cooking. This property ensures that food is evenly cooked and prevents hot spots or uneven heating. Additionally, aluminum is a highly corrosion-resistant material, which is crucial for food packaging. It helps to protect the food from external factors such as moisture, oxygen, and light, which can degrade the quality and freshness of the product. Aluminum coils can be easily formed into various shapes and sizes, making them ideal for packaging different food products, including cans, pouches, trays, and lids. Furthermore, aluminum is a lightweight material, which makes it convenient for transportation and reduces energy consumption during distribution. It is also recyclable, meaning that it can be reused, reducing the environmental impact of food packaging. Overall, aluminum coils are well-suited for food processing and packaging due to their excellent thermal conductivity, corrosion resistance, versatility, lightweight nature, and recyclability.

- Q: Can aluminum coils be used for electrical wiring?

- Yes, aluminum coils can be used for electrical wiring. Aluminum is a commonly used material for wiring due to its high conductivity and affordability. However, it requires special precautions and techniques during installation to ensure proper connections and prevent potential risks such as corrosion or overheating.

- Q: Can aluminum coils be customized?

- Yes, aluminum coils can be customized. They can be manufactured in various sizes, thicknesses, and shapes to meet specific requirements and applications. Additionally, they can undergo surface treatments, such as coatings or finishes, to enhance corrosion resistance or aesthetic appearance.

- Q: Is it possible to use aluminum coils in the creation of toys or games for children?

- <p>Yes, aluminum coils can be used to make toys or games for children, but safety considerations must be taken into account. Aluminum is a lightweight, durable, and non-toxic material, making it suitable for various applications, including children's toys. However, it's crucial to ensure that any aluminum used in toys is properly treated to prevent sharp edges or small parts that could pose a choking hazard. Additionally, the toys or games should be designed and manufactured to meet safety standards and regulations to protect children from potential harm.</p>

Send your message to us

032 Aluminum Coil Black Coated Aluminum Embossed Sheets with Cheap Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords