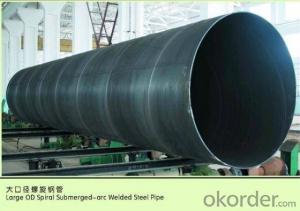

CNBM SPIRAL STEEL PIPE 3600MM

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

Packaging Detail: | standard export packing or as customer's requirement |

Delivery Detail: | within 10 - 30 days |

Specifications

Spiral Welded Steel Pipes and Tubes

1.Material:Q195-Q235

2.Length:1-12m

3.WT:1.0-14mm

4.O.D.:20-273mm

Spiral Welded Steel Pipes and Tubes

Product Description:

1.Material : Q235,Q345,L245,L290,L360,L415,L450,L485,GrB,X42,46,X52,X56,X60,X65,X70,X80,X100

2,Standard: SY/T5037-2000,GB/T9711-2011,API Spec 5L PSL1/PSL2,ASTM A252\A53,ISO3183,DIN17172,EN10217,JIS G3457,AWWA C200,ASTM A139,ASTM A671,ASTM A672

3.Wall thickness: 3.0mm-30mm

4.Outer diameter: φ168mm-3020mm

5,Length: 5m-12m or as your requirement

6,Corrosion protection standard: DIN30670,DIN30671, AWWAC210, AWWA C203, SY/T0413-2002,SY/T0414-2002

7,Application: Oil, gas, natural gas, water pipe, thermal electricity pipe, steel structure engineering, etc

Q195-q345 Material Steel Pipe's Materials

Elements | Chemical Compsition% | Mechanical Property | ||||||

| C% | Mn% | S% | P% | Si% | Yield Point (Mpa) | Tensile Strength(Mpa) | Elongation |

Q195 | 0.06-0.12 | 0.25-0.50 | <0.050 | <0.045 | <0.030 | >195 | 315-430 | 32-33 |

Q215 | 0.09-0.15 | 0.25-0.55 | <0.05 | <0.045 | <0.030 | >215 | 335-450 | 26-31 |

Q235 | 0.12-0.20 | 0.30-0.70 | <0.045 | <0.045 | <0.030 | >235 | 375-500 | 24-26 |

Q345 | <0.20 | 1.0-1.6 | <0.040 | <0.040 | <0.55 | >345 | 470-630 | 21-22 |

- Q: How are steel pipes threaded for easy installation?

- Steel pipes are threaded for easy installation by using a specialized machine called a pipe threading machine. This machine cuts precise threads onto the ends of the steel pipes, allowing them to be easily connected and tightened together using threaded fittings or couplings. This threading process ensures a secure and leak-proof connection, making installation quick and efficient.

- Q: Can steel pipes be used for underground sewer systems?

- Yes, steel pipes can be used for underground sewer systems. Steel pipes are known for their durability, strength, and resistance to corrosion, making them a suitable choice for underground applications such as sewer systems. However, it is important to consider factors like soil conditions, potential for corrosion, and local regulations before selecting steel pipes for an underground sewer system.

- Q: How are steel pipes used in the food processing industry?

- Steel pipes are commonly used in the food processing industry for various purposes such as conveying liquids, gases, and solids, as well as for structural support. They are used to transport ingredients, such as water, oils, and other liquids, from one area to another within the food processing plant. Steel pipes are also utilized for the distribution of compressed air or steam, which are essential for cooking, sterilization, and cleaning processes. Additionally, steel pipes are employed in the construction of equipment and machinery, providing a sturdy and reliable framework for various food processing operations.

- Q: What is the average lifespan of steel pipes in different applications?

- The average lifespan of steel pipes in different applications can vary depending on various factors such as the quality of the steel, the environment in which the pipes are used, and the maintenance and care they receive. In general, steel pipes used for water supply lines can have an average lifespan of around 50 to 70 years. This is because these pipes are typically made of high-quality steel and are subject to less corrosive environments. However, factors such as water chemistry, soil conditions, and the presence of corrosive substances can significantly influence the lifespan of these pipes. For steel pipes used in industrial applications such as oil and gas pipelines, the average lifespan can range from 20 to 50 years. These pipes are exposed to more aggressive environments, including high temperatures, pressure, and corrosive substances. Regular inspection, maintenance, and corrosion protection measures can help extend their lifespan. In construction applications, steel pipes used for structural purposes can have an average lifespan of 50 to 100 years or more. These pipes are typically designed to withstand heavy loads and are often protected by coatings or insulation to prevent corrosion. It's important to note that these are average lifespans and individual pipes may have shorter or longer lifespans depending on the specific conditions they are exposed to. Regular inspections, maintenance, and timely repairs or replacements when necessary can help ensure the longevity of steel pipes in different applications.

- Q: Can steel pipes be used for structural supports?

- Yes, steel pipes can be used as structural supports due to their high strength, durability, and ability to withstand heavy loads. They are commonly used in construction for applications such as columns, beams, and braces, providing stability and support to various structures.

- Q: What are the different coatings used on steel pipes?

- There are several different coatings used on steel pipes, including but not limited to, epoxy coatings, fusion bonded epoxy (FBE) coatings, polyethylene coatings, and zinc coatings. These coatings are applied to steel pipes to protect them from corrosion, increase their lifespan, and improve their performance in various environments.

- Q: What are the safety precautions while working with steel pipes?

- Some safety precautions while working with steel pipes include wearing appropriate personal protective equipment such as gloves, safety glasses, and steel-toed boots to prevent injuries. It is important to ensure the work area is clear of any obstacles or tripping hazards. Workers should be trained in proper lifting techniques to prevent strain or back injuries. Additionally, it is crucial to follow proper procedures for handling and storing steel pipes to prevent accidents and maintain a safe working environment.

- Q: What are the specifications for steel pipes used in high-pressure applications?

- The specifications for steel pipes used in high-pressure applications typically include requirements for the pipe material, such as high strength and resistance to corrosion, as well as specific dimensions, thickness, and wall thickness to withstand the pressure. Additionally, they may need to meet specific industry standards, such as ASTM or ASME, and be tested for quality assurance, including pressure testing and non-destructive testing methods.

- Q: How do you calculate the deflection of a steel pipe?

- To determine the deflection of a steel pipe, one must take into account various factors, including material properties, applied loads, and geometrical characteristics. The following steps can serve as a guide: 1. Material properties must be determined. This involves obtaining information about the steel pipe, such as its Young's modulus (E), which signifies its stiffness or resistance to deformation. Typically, this value is provided by the manufacturer or can be found in material databases. 2. The applied loads need to be analyzed. It is necessary to identify the types and magnitudes of the loads acting on the steel pipe. These loads can consist of point loads, distributed loads, or a combination of both. Additionally, the location and orientation of the applied loads must be determined. 3. The geometry of the pipe must be evaluated. The dimensions of the steel pipe, including its length (L), outer diameter (D), and wall thickness (t), should be measured or obtained. Accuracy in these values is crucial for precise calculations. 4. An appropriate calculation method should be selected. Depending on the complexity of the loading and support conditions, one may need to employ either simple beam theory or more advanced structural analysis methods, such as the finite element method (FEM). 5. The relevant equations must be applied. For simple beam theory, the Euler-Bernoulli beam equation can be utilized to calculate the deflection at a specific point on the pipe. This equation assumes the pipe is homogeneous, linearly elastic, and subjected to small deflections. In more complex scenarios, FEM software can handle the calculations. 6. Boundary conditions must be determined. The support conditions at both ends of the pipe, which can include fixed supports, simply supported ends, or combinations of both, need to be identified. These conditions significantly influence the deflection of the pipe. 7. The deflection can be calculated. By using the equations relevant to the chosen method and incorporating the material properties, applied loads, and geometry, one can calculate the deflection at specific points along the steel pipe. The deflection can be measured in terms of vertical displacement or angular rotation. It is important to note that calculating the deflection of a steel pipe may require specialized engineering knowledge and software tools. If one lacks experience in structural analysis, it is advisable to consult a professional engineer to ensure accurate results and safe design.

- Q: What is the typical diameter range of steel pipes?

- The typical diameter range of steel pipes can vary depending on various factors such as the intended application, industry standards, and specific project requirements. However, in general, steel pipes are available in a wide range of diameters to suit different purposes. Commonly used diameters for steel pipes can range from small diameters of around 0.5 inches (12.7 mm) to larger diameters of several feet or more. This range allows for various applications such as plumbing, oil and gas transportation, structural support, and industrial processes. Ultimately, the specific diameter of a steel pipe will be determined by the specific needs of the project or application at hand.

Send your message to us

CNBM SPIRAL STEEL PIPE 3600MM

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords