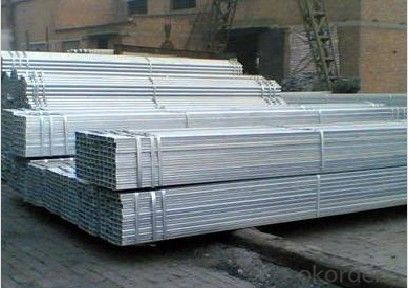

Rectangular steel tube from cnbm okorder.com

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1、Structure of Cold Finished Welded hollow Sections Grade: S355j2h En 10219size:100 X 100 X 6 M:

Black square&rectangular pipe welded pipe .factory steel ,ISO 9001

2、Main Features of Cold Finished Welded hollow Sections Grade: S355j2h En 10219size:100 X 100 X 6 M:

• High manufacturing accuracy

• High strength

• Small inertia resistance

• Strong heat dissipation ability

• Good visual effect

• Reasonable price

3、Cold Finished Welded hollow Sections Grade: S355j2h En 10219size:100 X 100 X 6 MSpecification:

Standard | GB, DIN, ASTM ASTM A106-2006, ASTM A53-2007 |

Grade | 10#-45#, 16Mn 10#, 20#, 45#, 16Mn |

Thickness | 8 - 33 mm |

Section Shape | Round |

Outer Diameter | 133 - 219 mm |

Place of Origin | Shandong, China (Mainland) |

Secondary Or Not | Non-secondary |

Application | Hydraulic Pipe |

Technique | Cold Drawn |

Certification | API |

Surface Treatment | factory state or painted black |

Special Pipe | API Pipe |

Alloy Or Not | Non-alloy |

Length | 5-12M |

Outer Diameter | 21.3-610mm |

Grade | 20#, 45#, Q345, API J55, API K55, API L80, API N80, API P110, A53B |

Standard | ASME, ASTM |

1) Material:20#(ASTM A 106/A53 GRB.API5LGRB,GB),45#,16Mn,10#.

2) Specification range:OD:21.3-610mm,WT:6-70mm,length:6-12m or according to the requirement of clients.

3) Excutive standards:GB,ASME API5L.ASTM A 106/A53,Despite of the above standards,we can also supply seamless steel pipe with standard of DIN,JIS,and so on,and also develop new products according to the requirements of our clients!

4) Surface:black lacquered,varnish coating or galvanized.

5) Ends:Beveled or square cut,plastic capped,painted.

6) Packing:bundles wrapped with strong steel strip,seaworthy packing.

4、Packaging & Delivery

Packaging Details: | seaworthy package,bundles wrapped with strong steel strip |

Delivery Detail: | 15-30days after received 30%TT |

5、FAQ of Cold Finished Welded hollow Sections Grade: S355j2h En 10219size:100 X 100 X 6 M:

①How is the quality of your products?

Our products are manufactured strictly according to national and internaional standard, and we take a test

on every pipe before delivered out. If you want see our quality certifications and all kinds of testing report, please just ask us for it.

Guaranteed: If products’ quality don’t accord to discription as we give or the promise before you place order, we promise 100% refund.

②How about price?

Yes, we are factory and be able to give you lowest price below market one, and we have a policy that “ for saving time and absolutely honest business attitude, we quote as lowest as possible for any customer, and discount can be given according to quantity”,if you like bargain and factory price is not low enough as you think, just don’t waste your time.Please trust the quotation we would give you, it is professional one.

③Why should you chose us?

Chose happens because of quality, then price, We can give you both.Additionally, we can also offer professional products inquiry, products knowledge train(for agents), smooth goods delivery, exellent customer solution proposals.Our service formula: good quality+good price+good service=customer’s trust

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem.

6、Cold Finished Welded hollow Sections Grade: S355j2h En 10219size:100 X 100 X 6 M Images:

- Q: What are the different methods of testing steel pipes?

- There are several methods of testing steel pipes, including non-destructive testing methods such as ultrasonic testing, magnetic particle testing, liquid penetrant testing, and radiographic testing. Destructive testing methods like tensile testing, bend testing, and impact testing can also be used to assess the strength and integrity of steel pipes.

- Q: Is steel pipe made of profiles?

- According to the shape of the cross-section, the steel is generally divided into profiles, plates, pipes and metal products in four categories.Therefore, the steel pipe belongs to the pipe, not the profile.

- Q: What are the advantages of using steel pipes in the manufacturing of storage tanks?

- There are several advantages of using steel pipes in the manufacturing of storage tanks. Firstly, steel pipes are highly durable and have a longer lifespan compared to other materials, ensuring the longevity of the storage tank. Secondly, steel pipes have high strength and can withstand high pressure and extreme temperatures, making them suitable for storing a wide range of substances. Additionally, steel pipes are resistant to corrosion and can be coated to further enhance their protection against rust and other chemical reactions. Lastly, steel pipes are readily available and can be easily fabricated, making them a cost-effective choice for the manufacturing of storage tanks.

- Q: Can steel pipes be used in extreme weather conditions?

- Yes, steel pipes can be used in extreme weather conditions. Steel is a durable and strong material that can withstand various weather conditions, including extreme temperatures, high humidity, and severe storms. Additionally, steel pipes can be coated or treated to provide additional resistance against corrosion, making them suitable for use in harsh environments.

- Q: What are the uses of welded steel pipes?

- Low pressure fluid conveying galvanized steel tube (GB/T3091-1993) is also called galvanized pipe, commonly known as white tube. It is used for hot water, gas, air, oil, heating, steam, warm water and other generally low pressure fluid or other hot dip galvanizing (furnace welding or welding) steel pipe. The wall thickness of the steel pipe is divided into ordinary galvanized steel pipe and thick galvanized steel pipe. The end of the pipe is divided into non - threaded galvanized steel pipe and threaded galvanized steel pipe. The specification of steel pipe is expressed by nominal caliber (mm). The nominal diameter is the approximate value of the inner diameter. Usually used in inches, such as 11/2.

- Q: How are steel pipes protected against external mechanical damage?

- Steel pipes are often protected against external mechanical damage through a variety of methods such as applying corrosion-resistant coatings, using protective sleeves or wraps, and implementing casing or encasement systems. These measures help to safeguard the pipes from potential physical harm caused by external factors like impact, abrasion, or heavy loads, thus ensuring their integrity and longevity.

- Q: How are steel tubes represented?

- If you speak of steel pipe, if it is water. Gas transmission pipe, then it is said: nominal diameter refers to the inner diameter. The units are millimeters or inches. [for example, water pipes with phi 25. It means that the nominal diameter (diameter) is 25mm (or an inch) steel pipe.

- Q: How do you measure the thickness of steel pipes?

- One common method to measure the thickness of steel pipes is to use a specialized tool called a pipe thickness gauge. This device consists of a small, handheld instrument with a probe that is inserted into the pipe. By applying pressure to the probe, the gauge can accurately determine the thickness of the pipe's wall. Additionally, ultrasonic testing can also be employed to measure the thickness by sending sound waves through the pipe and analyzing the reflections.

- Q: Seamless steel pipe 8162 and 8163 what is the difference?

- GB 8162 is the structure of the tube, there is no need for flaw detection, the use of mechanical processing, stents;

- Q: What is the difference between steel pipes and concrete-lined pipes?

- The main difference between steel pipes and concrete-lined pipes lies in their composition and protective features. Steel pipes are typically made entirely of steel, providing strength and durability. On the other hand, concrete-lined pipes consist of a steel pipe coated with a layer of concrete. This lining offers additional protection against corrosion and abrasion. While steel pipes are more suitable for high-pressure applications and offer better resistance to external factors, concrete-lined pipes are commonly used in wastewater systems to prevent corrosion and extend the lifespan of the pipe.

Send your message to us

Rectangular steel tube from cnbm okorder.com

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords