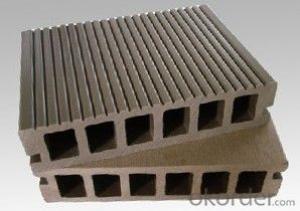

CMAX hollow WPC project decking for outdoor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Type: | Engineered Flooring | Place of Origin: | Beijing China (Mainland) | Brand Name: | CMAX |

| Model Number: | CMAX H150H25 | Technics: | Wood-Plastic Composite Flooring | use: | landscape |

| COLOR: | different color for choice | length: | 2.2m~6m | width: | 100mm~250mm |

| thickness: | 10mm~40mm |

Packaging & Delivery

| Packaging Detail: | REGULAR EXPORTING PACKAGE |

| Delivery Detail: | 15DAYS |

Specifications

10years warranty;

10days delivery time;

more flexible payment terms;

thousands of mould for choice.

STOCK FROM CHILE WAREHOUSE

STOCK FROM DUBAI LOGISTICS CENTER

BID FOR BIG CONSTRUCTION PROJECT

Landscape use wpc

1> What is WPC?

WPC, simply for wood plastic composite.

Wood Plastic Composite is made from a unique combination of plant fiber and recycled plastic

according to high-tech formula.

It offers the best advantages of plastic and wood. The plastic shields the wood from moisture and

insect damage, and the wood protects the plastic from UV damage and gives you a natural feel.

It has characteristics of high strength and rigidity, acid and alkali resistance, corrosion resistant

and without formaldehyde, it is a real green environment protection building material.

2> What’s WPC used for?

WPC can be used for military equipment, urban utilities and landscaping, architecture,

gymnasiums, outdoor decking, fencing, pallets, indoor and outdoor decoration.

3> Why choose WPC decking?

*Natural colour

*Slip resistant

*Resistance to water, rot and crack

*Guaranteed to last

*Low maintenance

*Beautiful and broad range of finish

4> What are the main kinds of WPC currently?

*WPC decking board

*DIY decking board

*WPC wall panel (wall cladding)

*Garden fence (railing)

*WPC outdoor furniture (gazebo, pavilion, outdoor desk&chair, dustbin, pet house…)

5> Ingredients of WPC?

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

6> Specification of WPC?

A. Weatherability

suitable from -40° C to +60° C, UV resistance

B. Test Data

| Testing Item | Technical Requirements | Value of Test |

| Water Content % | ≤2 | 0.4 |

Rockwell Hardness (HRR) | ≥60 | 80 |

Thickness Swelling after Water Absorption (%) | ≤1 | 0.2 |

Screw Holding | Surface of board ≥1300 | 3870 |

| End of board ≥1200 | 3460 | |

Static Bending | ≥20 | 28 |

Bending Elastic | ≥1800 | 4610 |

Abrasion | ≤0.08 | 0.06 |

Hammer falling impact in low temperature, broken (pcs) | ≤1 | 1 |

State after Heating | No babbles, cracks and pockmarks | - |

Rate of Size Change with Heating (%) | ±2.5 | -0.38~-0.45 |

Report Number: 201107126

Type of sample: 90x25x820mm, Solid

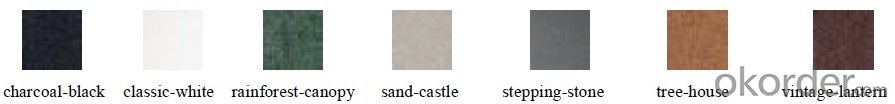

C. Main colors available:

charcoal-black; classic-white; rinforest-canopy;sand-castle; stepping-stone; tree-house; vintage-lantern .

- Q: 80 * 80 tiles multiple

- Thickness of 10mm, each weighing about 15 kilograms

- Q: I have laminate flooring my in my bathroom. The seem appears to have warped, How do I seal the seem once again? It is a wooden style flooring (but not the snap together type)

- Laminate floors are not actually wood. Engineered floors have a thin layer of wood on top. Hardwood floors are all wood. Laminate floors are only a picture of wood on top of a substrate. That substrate is usually something called MDF. MDF will swell when it gets wet. This is likely your problem. There is no repair except for replacing those sections. Tongue and groove laminate is glued together making this almost impossible. If you had hardwood floors they could be sanded and refinished. If you have engineered floors they might, or might not be able to be refinished, depending on the thickness of the veneer on top. Sorry for the bad news.

- Q: I want to redo my flooring, but the prices in the stores are ridiculous. I have a lot of loose stones in my driveway. Is there a way to scatter them evenly and glue them to the floor?

- Laminate is 1/3 of the price it used to be....The Best value on a budget is Home Depot's..Allure,..vinyl flooring that looks like hardwood flooring, also looks like Tile//It Floats like Laminate..It's not glued down..Which in my opinion is a great idea.especially if you live in flood prone areas. In 20 years,..It's worn, or you're tired of it,..it' not glued down..You literally grab it , and pull it out, and start over.

- Q: I will be using prepaded laminate flooring on top of a concrete slab. Do I need to use an adhesive ? How does the floor stay down ?

- is it a rolled sheet laminate floor? if so then yes u will need an adhesive to told it down...the direction on the glue will tell u what size V shaped notched trowel to use...must of the time you'll need a 1/8 trowel.....roll back the flooring half way and apply the glue to the floor....fold back over glue and press into place....u can rent a 100 lb. roller for this which help it stick to the floor and squeezes all the air out from underneath ...repeat for the other half of flooring....if no roller then press the floor into place with a soft towel

- Q: I now in charge of the company's wiring manager asked to do the wiring between the health, but how to clean the anti-static floor? In the clean wiring between the electrical room should pay attention to what?

- Cleaning: the floor from the wax water polished wash the floor, and then wash the floor with a neutral detergent; with water after cleaning, quickly dry the floor; floor completely dry, evenly coated with static electricity for electrostatic wax water. Maintenance: (1) should not take a sharp, rough weight on the floor surface to draw, drag, to avoid wearing a nail shoes walking on the floor; (2) free from the floor with a black rubber mat And other dark objects to prevent black sulfide from contaminating the floor. (4) the use of the floor to be kept dry, avoid prolonged soaking in water, resulting in floor degumming; (5) the surface of the floor if there are dirty dirt, can be used to remove the dirt (3) to prevent the floor will be discoloration, deformation; , The center of cleavage scrub, such as the local surface was scratched hair, available sandpaper with sand.

- Q: Why do price floors lead to surpluses? What is an example of a price floor?

- Price floor is a floor that you mop, for a price, typically in McDonalds restaurant. As a result of working there, you eat more food than you need, and you end up with surplus weight.

- Q: Wood floor moisture-proof pad is what material

- Open-type foam moisture-proof pad: generally made of expanded polyurethanes (polyurethane), which there are many subtle air chamber can allow the outside air into the formation of isolation layer. Its benefits are comfortable enough, light weight, and the price is not expensive; internal air chamber limits the flow of air, you can achieve a good isolation effect. The disadvantage is that it will absorb water, once encountered water can not be used; bulky, not easy to compress, the use of inconvenient, and the isolation effect is not closed foam waterproof pad to the good. Closed foam moisture-proof pad: the inside contains a lot of closed subtle air foam foam pad, the general market is divided into foam moisture pad, tin foil drained moisture-proof pad, folding moisture pad benefits is cheap, high durability , Even if the ice claws pedal, the same can be used; value for money isolation effect, because the air inside the closed air almost no flow, will not absorb water. The disadvantage is a certain weight, the thickness of the mat than the open-type moisture-proof pad is thin, so to choose a more heavy, sleep more comfortable. Automatic inflatable moisture-proof pad: the inside is open foam moisture-proof pad, the outer layer coupled with the organization of tight, good waterproof nylon cloth, at the same time in the corner with a inflatable valve to facilitate the flow of air is the advantage of comfort with open Foam waterproof tiles as well, but the isolation is better than the "open" outer layer of waterproof nylon cloth limit the moisture inside the moisture barrier, through the inflatable valve can adjust the size of moisture-proof pad size, and very solid, at any time Can maintain a certain thickness. The disadvantage is expensive; easy to be punctured or torn, although the repair technology is not difficult; weight heavier.

- Q: Describe the job of a floor nurse.Is it an important job?

- A floor nurse is just a basic staff nurse working on the floor of the hospital or nursing home. They are front line staff that are dealing with caring for the patients. Yes it is an important job.We are the ones that care for your loved ones while sacrificing time with our own.

- Q: I removed my carpet and put in laminate floor. Do you have to put a sealer for laminate floors. What products can i use to clean laminate floors??

- Laminate floors are already sealed. Use the product recommended by the floor company.I do small areas at a time with a swifter covered with a solution soaked rag. Then I dry it with a dry cloth on a swifter to prevent streaks.You may be able to forget the last step depending on the solution.

- Q: Living home multi-storey solid wood flooring

- Well, yes, life home multi-layer solid wood flooring and antique flooring in the industry is double champion, worth recommending!

Send your message to us

CMAX hollow WPC project decking for outdoor

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches