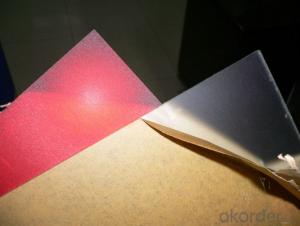

Plastic Sheets - Cmax-Cast Acrylic Sheet Covered with Kraft Paper on Both Sides

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Feature of colorful cast Acrylic sheet

Perfect transparency and the light transmittance up to 93%.

Excellent electrical insulation and light weight.

Good plasticity, easy to process and re-shape.

Strong surface hardness and good weather resistant property

Variety of colour, easy to clean

Applications of colorful cast acrylic sheet

Construction: show window, doors, light-absorpting shade, telephone booth.

Advertisement: lamphouse, signboard, indicator, display rack.

Vehicle: door and window of car and train.

Medical: infant incubator, many kinds of medical apparatus.

Civilian goods: bath room, art work, cosmetics, bracket.

Industrial: instruments and meters and protecting cover

Lighting: daylight lamp, ceiling lamp,lamp shade

colorful cast acrylic sheet Average Physical Properties

Specific gravity | 1.19-1.20 |

Hardness | M-100 |

Absorptivity of water (24h) | 0.30% |

Tension | colorful cast plexiglass sheet |

Coefficient of Rupture | 700kg/cm2 |

Coefficient of Elasticity | 28000kg/cm2 |

Bending | colorful cast plexiglass sheet |

Coefficient of Rupture | 1.5kg/cm2 |

Coefficient of Elasticity | 28000kg/cm2 |

Transmittance (parallel rays) | 92% |

Full rays | 93% |

Heat Distortion Temperature | 100oc |

Coefficient of Linear Expansion | colorful cast plexiglass sheet |

Ultimae Temperature of Continuous operation | 80oc |

Thermoforming Ranges | 140-180oc |

Insulation Strength | 20V/mm |

- Q: Can plastic sheets be used for greenhouse insulation?

- Yes, plastic sheets can be used for greenhouse insulation. They are commonly used as a cost-effective option to create a barrier that traps heat and helps maintain a stable temperature inside the greenhouse.

- Q: Are plastic sheets resistant to fading from sunlight?

- Yes, plastic sheets are generally resistant to fading from sunlight.

- Q: Does anyone have any suggestions?

- My cat did this when I first brought her home so I put a scratching post right by the couch and now she will very rarely scratch the couch.

- Q: Basically what are the pros and cons of plastic covering the ground in a effort to keep in warms, moister and produce a vegetable crops sooner in the ground,and bigger.Please don't say google people over there tend to get long winded, rabble on, and get off subject sometimes. Thank you in advance!!

- Yes, it is a very good idea: Heats up the soil. Keeps moisture in, and saves water. Prevents bad weed from coming back. You can use inverted bottles to drip irrigate. If you are in an area that has fungus in the soil, reduces infection. Prevents crows from digging, and making a mess.

- Q: Are plastic sheets resistant to impact from hail or debris?

- Yes, plastic sheets can be resistant to impact from hail or debris depending on their thickness and composition. Some types of plastic sheets, such as polycarbonate or acrylic, are known for their high impact resistance and durability, making them suitable for protecting against hail or debris damage. However, it is important to note that the level of resistance may vary depending on the specific type and quality of the plastic sheet.

- Q: Talk fast now.

- Pulling out the packet of fake blood I carry for such instances I say. See, officers, it's not real. I'm playing a joke on a friend.

- Q: i'm looking for some clear plastic sheets (similar to laminating) that i can use a dry erase markers on and place over the whiteboard in my classroom - for putting music notes on the staff etc.i don't want to rewrite them over and over. since there is no laminator in my school, i am at a loss for what to use. of course i can by laminating rolls. anything else i can use and where to get it?

- Draw them on thicker paper, and then buy contact paper (the sealing people put in cabinets). It is very inexpensive. Also, I have found, if you live by an university, it is fairly cheap to use their laminators.

- Q: There was like a plastic transparent sheet on the back of it. Some of it came off. And some of it is still there. The signature is still there too. Will it still work. Cause i dont want to peel itall off since if i do the sign will also come off.

- It may or may not work. Contact your card issuer and ask them to send you a replacement card. Some greedy banks may try to charge you for the replacement, but call them and make a big fuss - and they will waive the fee.

- Q: The one that is thicker than sliding folders. And in different colors.

- Maybe in a school supplies store or National Book Store

- Q: Are plastic sheets resistant to yellowing from sunlight exposure?

- Yes, plastic sheets are generally resistant to yellowing from sunlight exposure. They are designed to be UV resistant, which helps to prevent discoloration and maintain their clarity over time. However, the level of resistance may vary depending on the specific type and quality of plastic used.

Send your message to us

Plastic Sheets - Cmax-Cast Acrylic Sheet Covered with Kraft Paper on Both Sides

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords