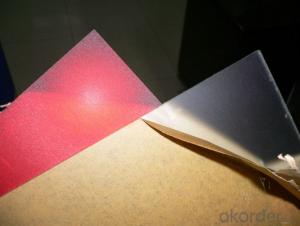

Plastic Sheets - Cmax Embossed Cast Acrylic Sheet for Two Sides

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Feature of colorful cast Acrylic sheet

Perfect transparency and the light transmittance up to 93%.

Excellent electrical insulation and light weight.

Good plasticity, easy to process and re-shape.

Strong surface hardness and good weather resistant property

Variety of colour, easy to clean

Applications of colorful cast acrylic sheet

Construction: show window, doors, light-absorpting shade, telephone booth.

Advertisement: lamphouse, signboard, indicator, display rack.

Vehicle: door and window of car and train.

Medical: infant incubator, many kinds of medical apparatus.

Civilian goods: bath room, art work, cosmetics, bracket.

Industrial: instruments and meters and protecting cover

Lighting: daylight lamp, ceiling lamp,lamp shade

colorful cast acrylic sheet Average Physical Properties

Specific gravity | 1.19-1.20 |

Hardness | M-100 |

Absorptivity of water (24h) | 0.30% |

Tension | colorful cast plexiglass sheet |

Coefficient of Rupture | 700kg/cm2 |

Coefficient of Elasticity | 28000kg/cm2 |

Bending | colorful cast plexiglass sheet |

Coefficient of Rupture | 1.5kg/cm2 |

Coefficient of Elasticity | 28000kg/cm2 |

Transmittance (parallel rays) | 92% |

Full rays | 93% |

Heat Distortion Temperature | 100oc |

Coefficient of Linear Expansion | colorful cast plexiglass sheet |

Ultimae Temperature of Continuous operation | 80oc |

Thermoforming Ranges | 140-180oc |

Insulation Strength | 20V/mm |

- Q: Company wants me to pay extra for it but why do I need it?

- Moisture, vegetation growth, radon. Many good reasons for it. Make sure it's air/water tight, no rips and the seams are taped with proper sealant tape. The higher mill the better. I think it's at least 6 mill. Pay attention and don't let them cheat you.

- Q: I need a cheap coin case for my morgan silver dollars would plastic card sheets which are like plastic sheets with card slots in them hold coins good and then i could make a book out of them which would be pretty cool. if you guys dont think this will work tell me some good coin holders.

- As was stated you do not want to store coins in any fashion where they can move. 2X2 staple type Mylar holders are very inexpensive. The 20 pocket 3 ring binder pages are also to too expensive. My main problem here is the coins falling out of the card pages no matter if in or out of a 2X2 holder. Cheap storage for coins in the long run, is always a bad idea and one can lose value on their coins real quick. Morgan dollars are usually always a hot item, so one needs to do them justice.

- Q: Can plastic sheets be used for printing?

- Yes, plastic sheets can be used for printing.

- Q: Can plastic sheets be used for insulation against sound or vibrations?

- Yes, plastic sheets can be used for insulation against sound or vibrations. They can help dampen vibrations and reduce the transmission of sound, making them a viable option for soundproofing applications.

- Q: What are the common uses for plastic sheets?

- Plastic sheets have a wide range of common uses, including but not limited to: packaging materials, construction and building applications (such as roofing, windows, and insulation), protective coverings for furniture or flooring, signage and advertising displays, medical and healthcare equipment, automotive parts, and various DIY projects.

- Q: What are the different surface treatments available for plastic sheets?

- There are several surface treatments available for plastic sheets, including: 1. Coating: Plastic sheets can be coated with various materials like acrylic or polyurethane to enhance their appearance, provide added protection against scratches, and improve chemical resistance. 2. Laminating: Lamination involves applying a thin layer of plastic film onto the surface of the sheet, which can provide additional strength, durability, and resistance to moisture, UV radiation, and chemicals. 3. Printing: Plastic sheets can be printed with designs, logos, or patterns using techniques like screen printing, digital printing, or offset printing, allowing for customization and branding opportunities. 4. Embossing: This treatment creates a textured or raised pattern on the surface of the plastic sheet, adding a tactile dimension and aesthetic appeal. 5. Etching: Etching involves chemically or mechanically altering the surface of the plastic sheet to create a matte or frosted appearance, reducing glare and improving light diffusion. 6. Varnishing: Applying a clear varnish to plastic sheets can provide a glossy finish, enhancing the visual appeal and protecting the surface from scratches and abrasion. These surface treatments offer a range of benefits, allowing plastic sheets to meet specific functional and aesthetic requirements in various industries such as automotive, packaging, construction, and signage.

- Q: You know how dvd cases are made of somewhat flexible plastic? Where can you find sheets of those? (if you even can)

- www.okorder They have all kinds of good plastics. And, they're pretty affordable.

- Q: What is the weight of a standard plastic sheet?

- The weight of a standard plastic sheet can vary depending on its thickness and size. However, on average, a standard plastic sheet typically weighs around 1.5 to 2.5 pounds per square foot.

- Q: I've been doing it the cheap way, with a manilla folder and I've also used a couple of mylar sheets. Obviously the mylar works best, but the folder gets the job done pretty good. Any suggestions on other materials?

- Hi: There are metal stencils for letters but carboard and poster board works geat for me which I use as well also there plastic stencil sheet that work just as good too. For any long term stencils the following ( the very best to the least is list in order) Metal Plastic Rubber Poster board Wax paper cardboard Manilla folders Paper Hope this helps.

- Q: Can plastic sheets be used for outdoor applications?

- Yes, plastic sheets can be used for outdoor applications. They are commonly used for outdoor signage, roofing, protection against weather elements, and as a barrier for construction sites. However, it is important to choose a plastic sheeting material that is specifically designed for outdoor use and is resistant to UV radiation and weathering to ensure durability and longevity.

Send your message to us

Plastic Sheets - Cmax Embossed Cast Acrylic Sheet for Two Sides

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords