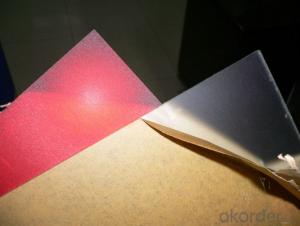

Cmax Anti-Fire Cast Acrylic Panel - Plastic Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Feature of antifire cast acrylic sheet

Excellent electrical insulation and light weight.

Good plasticity, easy to process and re-shape.

Strong surface hardness and good weather resistant property

Variety of colour, easy to clean

Applications of anti-fire cast acrylic sheet

Construction: show window, doors, light-absorpting shade, telephone booth.

Advertisement: lamphouse, signboard, indicator, display rack.

Vehicle: door and window of car and train.

Medical: infant incubator, many kinds of medical apparatus.

Civilian goods: bath room, art work, cosmetics, bracket.

Industrial: instruments and meters and protecting cover

Lighting: daylight lamp, ceiling lamp,lamp shade

anti-fire cast acrylic sheet Average Physical Properties

Specific gravity | 1.19-1.20 |

Hardness | M-100 |

Absorptivity of water (24h) | 0.30% |

Tension | colorful cast plexiglass sheet |

Coefficient of Rupture | 700kg/cm2 |

Coefficient of Elasticity | 28000kg/cm2 |

Bending | colorful cast plexiglass sheet |

Coefficient of Rupture | 1.5kg/cm2 |

Coefficient of Elasticity | 28000kg/cm2 |

Transmittance (parallel rays) | 92% |

Full rays | 93% |

Heat Distortion Temperature | 100oc |

Coefficient of Linear Expansion | colorful cast plexiglass sheet |

Ultimae Temperature of Continuous operation | 80oc |

Thermoforming Ranges | 140-180oc |

Insulation Strength | 20V/mm |

- Q: Are plastic sheets resistant to moisture absorption?

- Yes, plastic sheets are generally resistant to moisture absorption.

- Q: I just bought a few packages of sheets for the bed and I wanted to find some uses for those clear zippered bags that the sheets come in. What are some good uses for those?

- I use them to store papers such as receipts for filing income taxes. You can also use them to store photos before you get time to put them into photo albums. If you have excess cosmetics or hair appliances they can be stored in these bags and then slip them under your bed to save space.

- Q: Can plastic sheets be used for skirting boards or baseboards?

- Yes, plastic sheets can be used for skirting boards or baseboards. Plastic skirting boards are a popular alternative to traditional wooden baseboards due to their durability, low maintenance, and moisture resistance. They are available in various colors and designs, providing a modern and sleek finish to a room.

- Q: What are the load-bearing capabilities of plastic sheets?

- The load-bearing capabilities of plastic sheets vary depending on the type of plastic and its thickness. Generally, plastic sheets have a good strength-to-weight ratio and can support moderate loads. However, they are not as strong as materials like metal or wood and may deform or break under excessive weight or pressure. It is important to consider the specific plastic material and its specifications to determine its load-bearing capabilities accurately.

- Q: I usually sleep under a little tent sort of thing made out of tarp tied to stakes and trees and whatnot so that it resembled a sort of elongated prism. Anyway i used to have a big roll of heavy duty plastic sheeting. I would take like a 5x10 foot sheet of the stuff and tie the ends together so that it kind of resembled a piece of candy but was open in the middle so i could put my pad down and sleeping bag down inside and sleep inside it. I would do this because when the rain comes, none would get in from above but sometimes water would run underneath so I developed this canoe idea. Anyway I'm out of plastic sheeting and I forget where i bought it from. Can someone help?

- Home depot. Lowes. any construction material yard

- Q: Are plastic sheets resistant to chemicals used in automotive fluids?

- Yes, plastic sheets are generally resistant to chemicals used in automotive fluids. They are commonly made from materials such as polyethylene or polycarbonate, which have good chemical resistance properties. However, the exact resistance may vary depending on the specific type of plastic used and the specific type of automotive fluid involved.

- Q: What do you call the plastic sheets that x-ray s are embossed in?

- They are called negative plates.

- Q: We have had a problem with bug bites, and we're pretty curtain that its bed bugs, not mosquitos...I'm curious if those plastic sheets are good for that!

- it would be good when u get your new matress to get one of those sealers to help prevent anything serious like that to happen again. hope it works for u! :) clean the whole room some top to bottom with bleach.

- Q: Can plastic sheets be used for protective barriers in laboratories?

- Yes, plastic sheets can be used as protective barriers in laboratories. They can provide a physical barrier to protect against chemical splashes, airborne particles, and other potential hazards. Additionally, plastic sheets are often transparent, allowing for visibility and easy monitoring of activities within the laboratory.

- Q: Are plastic sheets transparent?

- Yes, plastic sheets can be transparent.

Send your message to us

Cmax Anti-Fire Cast Acrylic Panel - Plastic Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords