Scotch Super Strength Packaging Cloth Tape Synthetic Rubber Customized 70Mesh

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

·World Top 500 Enterprises

·Resistance to cold, heat and aging

·Best quality and competitive price

·SGS&ISO9001

Description

The Cloth Tape is of polyethylene cloth as the carrier, coating with hot melt adhesive, synthetic rubber adhesive or nature rubber. It is excellent in flame retardant, high temperature stability, and anti-aging. It provides well insulation to various products.

The thickness of the tape can be customized.

General purpose of Cloth Tape: widely used for pipe wrapping, gaffers and book binding etc.

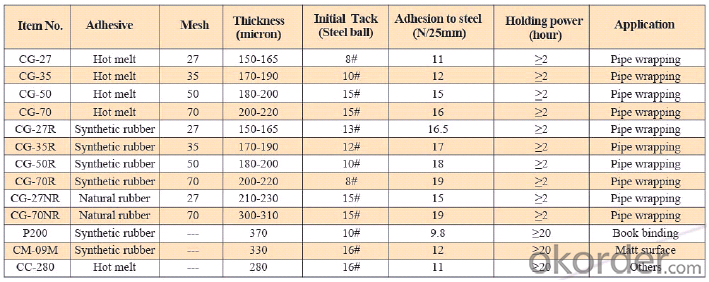

Typical Physical Reports of Cloth Tape:

The thickness of the tape can be customized.

Log Roll: Length 1000mm; width 1060mm.

Cut Roll: As per customer’s requirements

FAQ of Double Sided Tissue Tape

Q1. How about your company?

CNBM International Corporation (CNBM International) is a state-owned company and we have sound business relations with clients from over 120 countries. Currently, we have wholly-owned overseas subsidiaries and branches in 5 countries with a view to realize localization, which also represents an essential progress in our globalization target. We have over twenty years experiences.

Q2. What kind of service we can provide for you?

Sample of Cloth Tape is available.

Your inquiry will be replied within 12 hours.

24 hours service for you

Well-trained & experienced sales representative are ready to answer you.

Q3. How long can you receive the product?

Within 7-15 working days after receiving your deposit

Welcome to contact us and visit the factory!

- Q: How to adjust the tightness of belt pulley in belt sealing machine?

- Full automatic sealing machine, pneumatic sealing machine, folding lid sealing machine, corner sealing machine,

- Q: Is packaging tape easy to write on?

- Packaging tape is not particularly easy to write on. The smooth and glossy surface of the tape makes it challenging for most writing tools to adhere properly. Regular pens or markers may smudge or fade quickly, resulting in illegible writing. Additionally, the adhesive nature of packaging tape can cause ink to bleed, making it difficult to achieve clean and precise writing. Therefore, if you need to write on packaging tape, it is advisable to use a permanent marker or a specialized pen designed for writing on non-porous surfaces like plastic. These writing tools typically provide better results and ensure that your writing remains visible and intact.

- Q: Can packaging tape be used for sealing retail or product packaging?

- Yes, packaging tape can be used for sealing retail or product packaging.

- Q: Can packaging tape be used for outdoor applications?

- Outdoor applications can indeed make use of packaging tape. However, it is vital to recognize that not all packaging tapes are designed for outdoor use. Regular packaging tapes may not endure extreme weather conditions or UV ray exposure, leading to deterioration or loss of adhesive properties. To guarantee the durability and efficiency of packaging tape for outdoor applications, it is advisable to opt for specialized outdoor or weather-resistant packaging tapes. These tapes are engineered with stronger adhesives and materials that can withstand outdoor elements like rain, heat, cold, and sunlight. They are often composed of materials such as acrylic or rubber, which offer superior resistance to moisture, temperature changes, and UV rays. When selecting packaging tape for outdoor applications, it is crucial to take into account the specific requirements of the intended use. This may involve factors like the duration of exposure to outdoor conditions, the weight and size of the package, and the surface to which the tape will be applied. By choosing the appropriate outdoor packaging tape, you can ensure that your packages remain securely sealed and protected, even when subjected to outdoor environments.

- Q: Can packaging tape be used for shipping packages internationally?

- Yes, packaging tape can be used for shipping packages internationally. It is a common and reliable adhesive used to secure packages during transit, ensuring their safety and preventing any damage.

- Q: Is packaging tape resistant to chemicals or solvents?

- Generally, chemicals and solvents do not pose a threat to packaging tape. Packaging tapes are typically composed of materials like polypropylene or polyvinyl chloride (PVC), which possess excellent chemical resistance. These materials are specifically engineered to endure exposure to a broad array of chemicals and solvents commonly found in industrial or commercial settings. Nevertheless, it is crucial to acknowledge that the resistance of packaging tape may differ depending on factors such as the brand, type, and quality of the tape. Consequently, it is advisable to review the product specifications or seek guidance from the manufacturer to obtain detailed information regarding the chemical resistance of a particular tape.

- Q: Can packaging tape be used for securing shipments during transit?

- Absolutely, packaging tape is perfect for securing shipments while they are being transported. It is specifically engineered to create a sturdy and dependable seal for packages, guaranteeing their safety and preservation throughout transportation. It is commonly employed to seal cardboard boxes, fasten bubble wrap or other protective materials around items, and reinforce package closures. Packaging tape is long-lasting, user-friendly, and creates a strong adhesive connection, making it the ideal option for securing shipments in transit.

- Q: Can packaging tape be used for sealing packages with medical or pharmaceutical products?

- Indeed, packaging tape can certainly serve as a means to seal packages containing medical or pharmaceutical items. Nonetheless, it is crucial to take into account the precise requirements and regulations pertaining to packaging within the medical and pharmaceutical sectors. Such industries often uphold rigorous standards concerning packaging materials, aiming to guarantee the safety, soundness, and adherence to regulatory guidelines of the products. Consequently, it is advisable to opt for packaging tape specifically formulated and authorized for use in medical or pharmaceutical contexts. These tapes are typically composed of moisture-resistant and tamper-proof materials, ensuring a robust seal to safeguard the package's contents. By utilizing approved packaging tape, the quality and integrity of medical or pharmaceutical products can be preserved throughout storage and transportation.

- Q: How does packaging tape perform in freezing temperatures?

- Packaging tape performs differently in freezing temperatures compared to normal room temperatures. The performance of packaging tape can be affected by the extreme cold as it can become less adhesive and less pliable. The adhesive on the tape may become brittle and lose its ability to stick effectively to surfaces, resulting in the tape not adhering properly. Additionally, the tape itself may become more rigid and difficult to handle, making it harder to tear or cut. This can lead to challenges when sealing packages or boxes in freezing temperatures. Therefore, it is recommended to use specialized packaging tapes that are designed to withstand low temperatures if you need to package items in freezing conditions.

- Q: What are the different types of packaging tape available?

- There is a wide range of packaging tape options to choose from, each tailor-made for specific purposes and applications. Here are a few commonly used varieties: 1. Transparent packaging tape: This is the most commonly employed type of packaging tape due to its versatility. It is transparent and boasts a strong adhesive bond, making it ideal for sealing boxes and packages. 2. Brown packaging tape: Also referred to as "brown tape" or "packing tape," this tape is typically constructed from brown or tan-colored material and reinforced with fiberglass. It offers exceptional strength and durability for securing heavy or bulky packages. 3. Masking tape: Although not specifically designed for packaging, masking tape can be used for light-duty sealing or labeling needs. It is easily removable and leaves no residue, making it suitable for temporary applications. 4. Duct tape: Renowned for its strength and versatility, duct tape is not primarily intended for packaging purposes but can be utilized in certain situations. It possesses a powerful adhesive bond and is known for its ability to stick to various surfaces, including uneven or rough ones. 5. Filament tape: This tape is fortified with fiberglass filaments, providing incredible strength and resistance. Filament tape is commonly used for bundling or reinforcing heavy or irregularly shaped items. 6. Double-sided tape: Unlike other packaging tapes, double-sided tape has adhesive on both sides and is employed for a variety of applications, such as bonding two surfaces together or mounting objects. 7. Kraft paper tape: Crafted from a renewable resource, kraft paper tape serves as an eco-friendly alternative to plastic tapes. It requires moistening before application as it is water-activated. Kraft paper tape delivers a robust seal and is often utilized for sealing cartons or packages that contain valuable or fragile items. 8. Colored packaging tape: This tape comes in a range of colors and is commonly used for color-coding packages, labeling, or enhancing the aesthetic appeal of packages. These represent just a few of the packaging tape options available in the market. Each type possesses its own distinct characteristics and is suitable for specific packaging requirements. When selecting the appropriate tape, it is crucial to consider factors such as the weight and nature of the package, the environment it will be exposed to, and any specific regulations or requirements that may be applicable.

Send your message to us

Scotch Super Strength Packaging Cloth Tape Synthetic Rubber Customized 70Mesh

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 20000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords