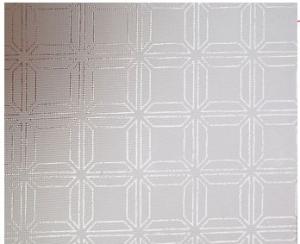

Clear Pattern Glass RH-5

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25T m.t.

- Supply Capability:

- 500 Tons per day m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Model Number: Clear RH-5 Pattern Glass

Function: Acid Etched Glass,Heat Absorbing Glass

Shape: Flat

Structure: Solid

Technique: Clear Glass,Figured Glass,Frosted Glass

Type: Pattern Glass

Product Name: Pattern Glass

Size: 1500*2000mm, 1830*2440mm

Thickness: 3.5mm, 4mm, 5mm

MOQ: 25Tons

Payment Terms: T/T or L/C

Packing: Wooden crates worthy for ocean and land carriage.

Delivery Detail: Within 15 to 25 days after deposit payment or L/C

Features of Pattern Glass

Its wide range of patterns makes it highly suitable for decorative applications. Its surface patterns allow diffused daylight transmission but prevent visibility of activity, thus ensuring privacy.

- Q: Do solar panels use toughened glass, or are some high light transmitting materials good?

- Ultra white glass raw materials imported or made of iron high transmittance (transmission rate of up to 92%), through tempering (heating quenching), so that the strength of the glass increased 3--5 times, broken glass debris particle degree of safety, no harm to human body. The thickness of 2MM, 3MM, 3.2MM 4MM, etc..

- Q: How is glass made? What are the main ingredients?

- Preparation of batch. According to the product, the composition of the mixture is slightly different. For example, ordinary float glass batch (calculated in accordance with 1 weight boxes of 50 kilograms), need to consume 33.55 kg of quartz sand, limestone, dolomite, 2.96 kg 8.57 kg 11.39 kg of soda, Glauber's salt 0.55 kg, 3.45 kg, 0.03 kg of feldspar powder etc..

- Q: Renovation of the house to buy bricks when how to see the quality of good or bad? What kind of good?

- Mosaic is mainly divided into glass mosaic (raw materials for glass) and ceramic mosaic two. Mainly used for decorative wall.

- Q: Long plastic soft glass is a food grade raw materials?

- No, this is the PVC material processing process, there will be plasticizers, etc., although non-toxic, harmless, but the food grade standards or worse.

- Q: What kind of raw material is glass made of?

- Composition of common glass chemical oxides (Na2O, CaO, 6SiO2)Glass is usually divided into oxide, glass, and non oxide glass by major components. Non oxide glass varieties and a small number, mainly sulfur glass and halide glass. Chalcogenide glass anion for sulfur, selenium and tellurium, can stop short wave light by yellow, red, and near infrared light, which has low resistance, switching and memory characteristics. Having low refractive index, low dispersion, and often used as optical glass.

- Q: The practice of acid corrosion in tank

- The construction of excellent anticorrosive paint can in a variety of conditions, including exposure to atmospheric environment, can be conveniently carried out in various forms such as painting, brush painting, and meet the requirement of the design of coating thickness and structure.

- Q: How is glass made, raw material proportioning?

- The manufacturing technology of the use of glass a thousand li a day, increasing by the clock, glass, doors and windows, lamps, such as high-tech electronic components and space technology, are indispensable glass. Our daily contact with most of the "flat glass is" thick to thin for doors and windows, clocks and the use of medical tests, the manufacturing method is that the furnace in the glass slurry level or traction method (also called float) and vertical traction method. After the dissolution of soluble traction after furnace also has the cooling system, cooling after the completion into a "flat glass, flat glass thickness mainly depends on the speed of traction, traction faster, can be manufactured and thinner. Although the ordinary flat glass from the front appears bright transparent, but from the side near the edge is slightly blue, because the amount of glass color depends on the main raw material in the manufacture of glass - quartz sand and iron content of purity. Generally, the thin glass used in the watch industry is superior in quality but expensive in value, mainly because the material used in quartz sand is superior and the iron content is very low (usually under 3/10000)

- Q: Will toughened glass break naturally?

- This is because of containing nickel sulfide crystal glass raw material, manufacturing technology in the world is any existing can not be completely avoided, only reduce the exploding probability through control of the purity of raw materials and processing technology to a.

- Q: What is the raw material of glass?.

- Glass material is complex, but can be divided into main raw materials and auxiliary raw materials according to its function. The main material constitutes the main body of the glass, and determines the main physical and chemical properties of the glass. The auxiliary material endows the glass with special properties and facilitates the manufacturing process.

- Q: What are the production processes and raw materials of float glass?

- The qualified mixture is then sent to a glass furnace, and in the range of temperature, a uniform glass solution is obtained by melting, clarification, homogenizing and cooling. The glass liquid through the flow passage and launder into the tin bath filled with protective gas of nitrogen and hydrogen, floating on the surface of molten tin, complete glass liquid natural tree, thin, flat show polishing, after cooling, with glass transition roller table hold left into the annealing annealing and tin bath. The annealed glass band can be taken as a product after cutting, checking and packing.

1. Manufacturer Overview

| Location | Shandong,China (Mainland) |

| Year Established | 2001 |

| Annual Output Value | Above US$100 Million |

| Main Markets | North America5 South America 22 Eastern Europe 4 Southeast Asia 7 Africa 25 Oceania 6 Mid East 25 South Asia 6 |

| Company Certifications | AS/NZS2208:1996 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao,Tianjin,Dalian |

| Export Percentage | |

| No.of Employees in Trade Department | 11-20 People |

| Language Spoken: | English, Chinese, Spanish, Portuguese, Arabic, French, Russian |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | 6 |

| Contract Manufacturing | OEM Service Offered Design Service Offered Buyer Label Offered |

| Product Price Range | Low and/or Average |

Send your message to us

Clear Pattern Glass RH-5

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25T m.t.

- Supply Capability:

- 500 Tons per day m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches