Clean Aluminum Sheets for Circle Cutting in Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium Sheet for Circle Cutting for Cookware Description:

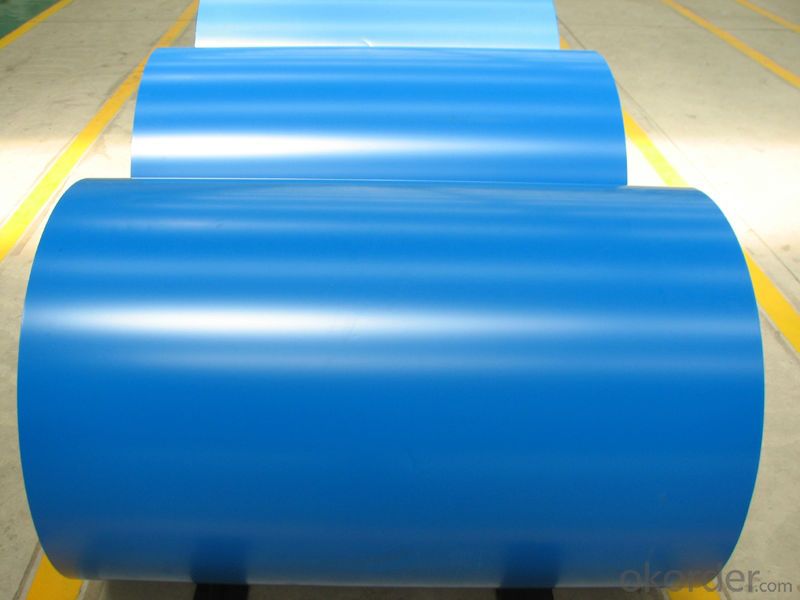

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium Sheet for Circle Cutting for Cookware:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of the Aluminium Sheet for Circle Cutting for Cookware:

Aluminium Sheet for Circle Cutting for Cookware Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: How do aluminum sheets perform in terms of heat reflectivity?

- Aluminum sheets exhibit remarkable heat reflectivity, making them exceedingly efficient. Their ability to effectively deflect heat and light away from surfaces minimizes heat absorption, thus rendering them perfect for scenarios where heat control is paramount, like roofing, insulation, and solar panels. The reflective quality of aluminum sheets aids in curbing energy consumption by preventing excessive heat accumulation, leading to a cooler atmosphere. Moreover, the reflectivity of aluminum also lends itself to a multitude of industrial and scientific applications, including the production of reflectors, heat sinks, and optical mirrors.

- Q: need help choosing an aluminum welder at a descent price also

- i think, welding,,, tig is right machine for aluminum, thank you.

- Q: Is aluminum a metal or a non-metal?

- Aluminum is a metal.

- Q: Can aluminum sheets be used for water tanks?

- Yes, aluminum sheets can be used for water tanks. Aluminum is a lightweight and corrosion-resistant material, making it suitable for storing water. It is commonly used in industries such as aerospace and marine due to its durability and ability to resist rust and corrosion. Aluminum tanks are also easier to transport and install compared to other materials, and they can withstand high pressure and extreme temperatures. However, it is important to ensure that the aluminum sheets used for water tanks are of high quality and meet the necessary standards to ensure the safety and longevity of the tank.

- Q: will it influence powder injection effect after wiping the oil contamination on the surface of aluminum sheet?

- It’s possible, there are several problems: 1, workers won’t wipe it thoroughly and fully, so you can wipe it after soaking. 2, the wiping efficiency is low, and we can use ultrasonic to clean it. 3, the water is poisonous and harmful to environment and workers’ health, so you can use water base to clean it, environmental and non-poisonous. Of course, if you really want to change, you can use detergent special for aluminum materials cleaning of our company, Changlvfeng chemical industry company. a, its PH value is 6.8-7.2 and it is totally an neutral liquid. b, good material applicability, detergent invented for aluminum materials. c, good degreasing ability, it has a good degreasing function for various oil contamination in processing and has no effect on material.

- Q: How do aluminum plates drill?

- There are many drilling equipment for aluminium sheets,First, the engraving machine can be big or small, and can shape strange.Can also be a self tapping screw drill, which can drill.

- Q: This question asks if there are distinctions among various coatings applied to aluminum sheets.

- <p>Yes, there are significant differences between different types of coatings on aluminum sheets. These differences can include the purpose of the coating, such as for corrosion resistance, decorative effects, or enhanced durability. The materials used for the coatings can also vary, with options like anodizing, powder coating, or paint. Each type of coating has unique properties, such as resistance to weather, chemicals, or UV rays, and they can affect the surface appearance, weight, and cost of the aluminum sheet. The choice of coating often depends on the specific application and environmental conditions the aluminum sheet will be subjected to.</p>

- Q: This question asks for methods to ensure a project remains cost-effective when using aluminum sheets.

- <p>To ensure your project is cost-effective using aluminum sheets, first, source high-quality aluminum at competitive prices. Consider buying in bulk to reduce per-unit costs. Second, optimize your design to minimize material usage without compromising strength. Use precise cutting techniques to reduce waste. Third, collaborate with reliable suppliers who can offer cost-effective solutions and may provide discounts for long-term partnerships. Lastly, monitor and control your project's budget closely, and consider the lifecycle costs, including maintenance and potential resale value, to ensure long-term cost-effectiveness.</p>

- Q: which is the best bonding method for aluminum sheet and plastic?

- smear glue, there is a glue special for the bonding of plastic and steel materials.

- Q: Are aluminum sheets suitable for packaging applications?

- Yes, aluminum sheets are highly suitable for packaging applications due to their lightweight, corrosion-resistant, and excellent barrier properties. They can effectively protect products from moisture, light, and oxygen, ensuring longer shelf life and freshness. Additionally, aluminum sheets are easily formable, making them suitable for various packaging formats like cans, foils, and pouches.

Send your message to us

Clean Aluminum Sheets for Circle Cutting in Cookware

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords