Chromium Alloyed Grinding Ball Well Quality and Abrasive Resisitance For Cement Plant

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. The Size and Chemical Composition of Chromium Alloyed Grinding Ball Well Quality and Abrasive Resisitance For Cement Plant

No. | Diameter (mm) | Weight of each (kg) | Pcs/ton |

1 | Ø20 | 0.0322 | 31056 |

2 | Ø25 | 0.063 | 15873 |

3 | Ø30 | 0.11 | 9091 |

4 | Ø40 | 0.257 | 3891 |

5 | Ø50 | 0.50 | 2000 |

6 | Ø60 | 0.867 | 1153 |

7 | Ø70 | 1.37 | 729 |

8 | Ø80 | 2.05 | 487 |

9 | Ø90 | 2.90 | 345 |

10 | Ø100 | 4.00 | 250 |

11 | Ø110 | 5.30 | 188 |

12 | Ø120 | 6.80 | 147 |

13 | Ø125 | 7.75 | 129 |

14 | Ø130 | 8.74 | 114 |

Model | Mechanical properties | Microstructure | |

HRC | Times of falling (3.5m) | ||

Low Chromium | ≥45 | 8000 | P+C |

Medium Chromium | ≥50 | 8000 | P+C |

High Chromium | ≥56 | 8000 | M+C |

Model | Chemical Composition | |||||

C | Si | Mn | Cr | P | S | |

Low Chromium | 2.3-3.4 | ≤1.5 | 0.5-1.5 | 1.0-2.0 | ≤0.1 | ≤0.1 |

Medium Chromium | 2.2-2.8 | 0.5-1.0 | 0.5-0.8 | 10.0-12.0 | ≤0.1 | ≤0.1 |

High Chromium | 2.4-3.2 | 0.5-0.8 | 0.5-0.8 | 16.0-18.0 | ≤0.1 | ≤0.1 |

4. Applied Field of Chromium Alloyed Grinding Ball Well Quality and Abrasive Resisitance For Cement Plant

1) Power Plant, 2) Mineral Processing,

3) Refractory Factory, 4) Cement Plant

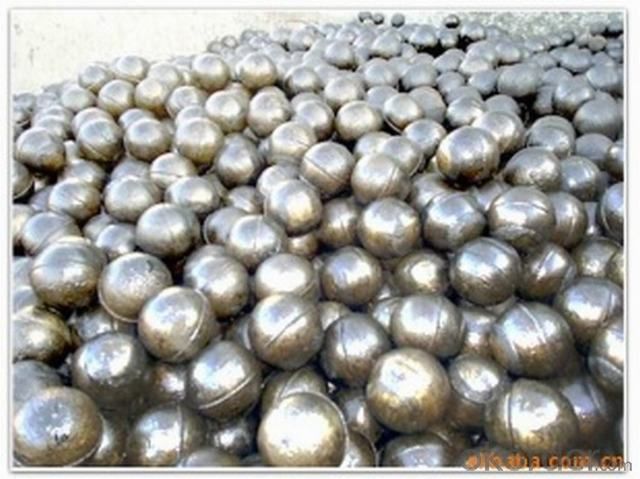

5. Photos of Chromium Alloyed Grinding Ball Well Quality and Abrasive Resisitance For Cement Plant

- Q: Why does the surface of stainless steel casting mirror mirror ripple?

- The surface can be improved by a little more than Xiasha

- Q: What is normalizing, annealing, tempering, quenching? What is the difference between forging parts and casting parts?

- For the nodular cast iron, the hardness, strength and wear resistance are improved, such as used in the manufacture of automobile, tractor, diesel engine crankshaft, connecting rod and other important parts. A normalizing and hypereutectoid ball annealing before, can eliminate the mesh two cementite spheroidizing annealing, to ensure that all spheres of cementite. Annealing is a metal heat treatment process, which means the metal is slowly heated to a certain temperature, sufficient for a long time, and then cooled at an appropriate speed. The purpose is to reduce hardness, improve machinability, eliminate residual stress, stabilize size, reduce deformation and crack tendency, refine grain, adjust microstructure and eliminate tissue defects. Its purpose: (1) reduce hardness and improve machinability; (2) eliminate residual stress, stabilize size, reduce deformation and crack tendency; (3) refine grain, adjust microstructure and eliminate tissue defects. In production, annealing process is widely used.

- Q: What is the ejection angle of the die casting (Tan Gang)?

- Because after the wax, wax parts will have a slight contraction, which is good for demoulding. Many moulds don't do the ejection angle

- Q: How to get rid of casting sand inside casting parts?

- Are you saying that in the sand casting cavity? We use the manual blast, he is like a pipe will be automatic shot out of the grit, into the casting cavity, to remove the internal cavity in the purpose of casting sand!

- Q: What's the density of the cast iron? The density is thin and the density is thin

- Generally cast iron thick place, density is empty, thin place density a little more.

- Q: For example, casting parts contain many holes, inclusions and other defects, the size and the number of holes exceed which limit is not qualified

- For example, the castings shall be in accordance with the requirements of the second types of castings in the technical requirements for aluminum alloy castings of GB/T9438-1999;

- Q: What are the causes of pitting on the surface of a precision casting?

- There is a bump on the mold. Or casting cooling fast.

- Q: We are small castings, the need for surface treatment of shot blasting machine, about how much?

- The choice of shot blasting machine, this is according to the workpiece size, yield, whether can collision, and the working time and other factors considered, while the price of different blasting machine are not the same, but the vast majority of small castings used crawler shot blasting machine, according to the comprehensive consideration of factors such as yield, size of workpiece commonly used on the market the crawler shot blasting machine has Q324, Q326, Q328, Q3210, and each time the amount of their treatment were 125KG, 200KG, 400KG, 600KG, the specific use of what types also need to be determined according to the actual situation

- Q: Younger brother is to do casting valve, precision casting parts, the valve internal sand serious, but the appearance is very standard, this is why, for God answers, thank you!

- Increase the refractoriness and looseness of core sand

- Q: What are the general technical requirements for casting parts?

- According to the national standard GB/T 9438, there are 8 aspects: 1. chemical composition; 2. delivery status; 3. mechanical properties; 4. dimensional tolerances; 5. weight tolerances; 6. appearance quality; 7. internal quality; 8. casting salvage.

1. Manufacturer Overview

| Location | Shandong, China |

| Year Established | 1983 |

| Annual Output Value | Above US$100 Million |

| Main Markets | South Asia, South Asia, Central America, Western Europe, Eastern Asia, Mid East, Oceania, Africa |

| Company Certifications | ISO9001;IS014001 Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao Port |

| Export Percentage | |

| No.of Employees in Trade Department | 3-5 People |

| Language Spoken: | English;Chinese;Japanese;Korean |

| b) Factory Information | |

| Factory Size: | Above 20,000 square meters |

| No. of Production Lines | 8 |

| Contract Manufacturing | Grinding steel balls;Grinding steel cylpebs;Grinding media;Grinding meida ball |

| Product Price Range | Average |

Send your message to us

Chromium Alloyed Grinding Ball Well Quality and Abrasive Resisitance For Cement Plant

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25M.T. m.t.

- Supply Capability:

- 200000M.T./Year m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords