CHINESE HIGHT QUANLITY LOW CARBON FERRO CHROME WITH BEST PRICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Ferro Chrome

Chrome is always used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized.Micro-Carbon ferro chorme is applied to making stainless, acid-resistant steel and heat resistant steel.

Chrome is mainly used to improve the antioxidation and corrosion resistance of steel to make the surface of steel after it is oxidized to form strong adhension oxide film. Then it stops being oxidized or decelerates being oxidized. Micro-carbon ferro chrome is applied to making stainless steel, acid-resistant steel and heat resistant steel.

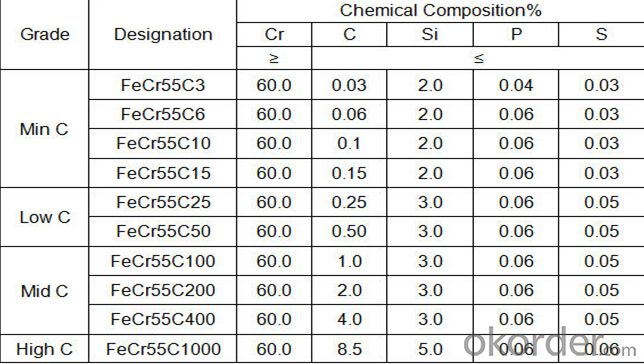

Specifications

Low Carbon Ferro Chrome

1. Original manufacturer

2. The stability of the shipments

3. Free samples

4. Relatively lower cost

Products information

1. It can be used to produce FerroChrome and Chrome metal in metallurgy industrial.

2. As a kind of steel addition,it is used to produce various special steels with high strength,corrosion resistance,anti-friction,thermostability and anti-oxydic.such as stainless steel,acid-resistant steel,heat-resistant steel,spring steel,tool steel and so on.

3. Chromite is used to produce Chrome brick,,Chrome-magnesium brick and other special refractories in fireproofing.

Specifications

1. Ferro chrome

1).Type;HC MC LC

2).Brand:FeCr67C6.0,FeCr55C600,etc

3).strict quality control

4).Factory price

2. High Carbon Ferro Chrome

Ferro Chrome

FeCr

1).ChemicalCompositions:Fe,Cr,C,Si,P,S

2).Type:High,Medium,low,MicroCarbon

3).FeCr67C6.0,FeCr55C600,etc

4).Improve antioxidation.

Packaging & Delivery

Packaging Detail: | 1MT/BAG |

Delivery Detail: | 15-30days |

- Q: MIG and TIG welding of cobalt base carbide and medium low carbon steel, respectively, using copper wire and stainless steel wire. What kind of corrosive liquid should be used in the welding seam to be metallographic?MIG+ copper welding wire, MIG+ stainless steel wire, TIG+ stainless steel wire

- According to the usage, the cobalt based alloy can be divided into cobalt base alloy wear, high temperature resistant cobalt and cobalt base alloy abrasion and corrosion of the alloy in aqueous solution. The general condition is both wear resistant or wear resistant and corrosion resistant performance, some conditions may also require high temperature wear resistance and corrosion resistance, and more in this complex condition, the more it can reflect the advantage of cobalt base alloy.

- Q: What is called cemented carbide?

- Hard alloy with high hardness, strength and toughness, good wear resistance, heat resistance, corrosion resistance and a series of excellent performance, especially high hardness and wear resistance of it, even at a temperature of 500 DEG C also remained unchanged, at 1000 degrees C still have high hardness. Hard alloy are widely used as tool materials. Such as turning, milling, planing, drilling, boring, used for cutting cast iron, non-ferrous metals, plastics, chemical fiber, graphite, glass, stone and steel, can also be used for cutting steel, stainless steel, high manganese steel, tool steel and other hard processing materials. Hundreds of times now cutting speed of new carbide tool is carbon steel.Carbide can also be used to make rock drilling tools, mining tools, drilling tools, measuring tools, wear-resistant parts, metal abrasives, cylinder liner, precision bearings, nozzles and so onIn the past twenty years, coated carbide also come out in Sweden.1969 in the successful development of titanium carbide coated tools, the tool is a matrix of tungsten carbide titanium carbide cobalt alloy or cobalt tungsten carbide, titanium carbide surface coating thickness of only a few microns, but with the same grade alloy tool compared to prolong the service life of 3 times, cutting to increase the speed of 25% ~ 50%.20 in 70s has been fourth generation coating tools, can be used for cutting hard processing materials.

- Q: What are the standard units of measurement for carbide inserts?

- It used to be priced by KG, and now it's on a tablet basis

- Q: I am 985 material girls graduated, looking for a job, want to know about

- There's such a funny thing.... Are you a small master or an undergraduate? I sign the hard line, my roommate in Xiamen tungsten gol-egret, 12 years has just signed, are made of hard alloy (oh, because we are the master of Science in powder metallurgy). Small master just entry, Xiamen tungsten and hard line treatment almost (Internship: hard line 3500, Xiamen tungsten Heron 3700; we are not 985, ha ha), Xiamen tungsten boys to shift the hard line, anyway, learning materials do not shift.

- Q: What are the parameters of the wear resistance of cemented carbides in addition to their hardness?

- Even the best knives in the world, if not1, reasonable processing parameters;2 、 proper installation and use;3 、 timely maintenanceAnd so on, it will turn into a scrap of iron in a short time.

- Q: Carbide and carbon steel

- Hard alloy knife, cutting knife, carbon steel is the food, so simple.

- Q: What are the fields of nano WC Cemented Carbides applied?

- (4) medical application. The drill is a fine medical instrument, the incision must be sharp, but also has good abrasion resistance and toughness, application of ultrafine grain WC hard alloy with high strength, high toughness and wear resistance in this field widely. (5) other applications. Nanocrystalline WC hard alloy because of its fine grain, as the cutting tool can grind the cutting edge radius and high precision, sharp nose arc; because of its high strength can be used for making fine tool rake angle, feed rate and small amount of snacks knife, such as small diameter cutter, reamer etc. because of its high elasticity; modulus and friction wear properties, can be used for the production of high precision mould, punch etc.; also can be used for the production of high wear resistance, erosion resistance, such as high-pressure nozzle, valve, high-pressure gun, glass cutter, cutter and textile tape, tape cutter etc.. In addition, scientists are developing circular tools, rock drilling tools and nano WC-Co based reinforced composites. Therefore, the development of nano WC cemented carbide and the search for wider applications become the focus of development, and the key technology of preparation is the preparation of nano powder and the subsequent sintering process. Particle size is to improve the performance of WC-Co hard alloy (strength, hardness and wear resistance of the Jun effective way, therefore the development of nano cemented carbide is the development focus of the next phase of the study, it will greatly broaden the application field of WC-Co hard alloy, and thus lead to a variety of precision instruments, mold, tool and electronic communication technology rapid development.

- Q: What are the common kinds of cemented carbides?

- The grade by "YW" ("hard", "million" Pinyin prefix) and sequence number, such as YW1. (2) grade, composition, performance and application of commonly used hard alloy (see table below) categories of chemical composition of W/% grade performance scope of tungsten cobalt alloy YG3X 96.5 - < 0.53 for cast iron, nonferrous metals and alloy fine boring, fine car, can also be used for fine machining of alloy steel, Quenched steel and tungsten and molybdenum materials; high tungsten carbide content, binder content is low, its high hardness, flexural strength is low; therefore, YG3 is suitable for finishing; whereas the YG15 can bear larger load, suitable for roughing. Suitable for cast iron, nonferrous metals and alloys and non metallic materials roughing during continuous cutting, interrupted cutting of the semi refined car, fine car for percussive rotary drilling machine drilling hard rock, containing coal cutter teeth, hard rock drill, well drilling hard rock percussion drill bit, stamping die, planer and knife for percussive rotary drilling machine and other chisel hard and extremely hard rock, in the epidermis processing great work under stress perforation and stamping tools tungsten titanium cobalt alloy YT5 855 - 10 for carbon steel, alloy steel, forging, stamping, casting, uneven section, rough turning, discontinuous cutting the rough plane semi finishing.

- Q: I've seen a lot of classification, what tools, hardware, machinery, machinery, metallurgy, minerals, etc.,But I always don't know what the hard alloy belongs to. What can I do for you?

- Cemented carbide is a powder metallurgy product, mainly used in cutting tools, belonging to the tool industry. Other powder metallurgy products should belong to the machinery manufacturing industry.

- Q: What materials are hard alloys used to process?

- YT hard alloy, resistant to impact, high temperature, processing steel, aluminum and so on.

Send your message to us

CHINESE HIGHT QUANLITY LOW CARBON FERRO CHROME WITH BEST PRICE

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches